Nissan Leaf. Manual - part 493

LI-ION BATTERY

EVB-255

< UNIT DISASSEMBLY AND ASSEMBLY >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

b. Use an insulated torque driver (A) and tighten the voltage detec-

tion terminal mounting screws to the prescribed torque.

DANGER:

•

There is the danger of electric shock caused by

contact with the terminals. Be sure to wear insulated pro-

tective gear and use insulated tools.

•

This work must not be performed by multiple opera-

tors because there is a risk of electric shock if the operators contact one another.

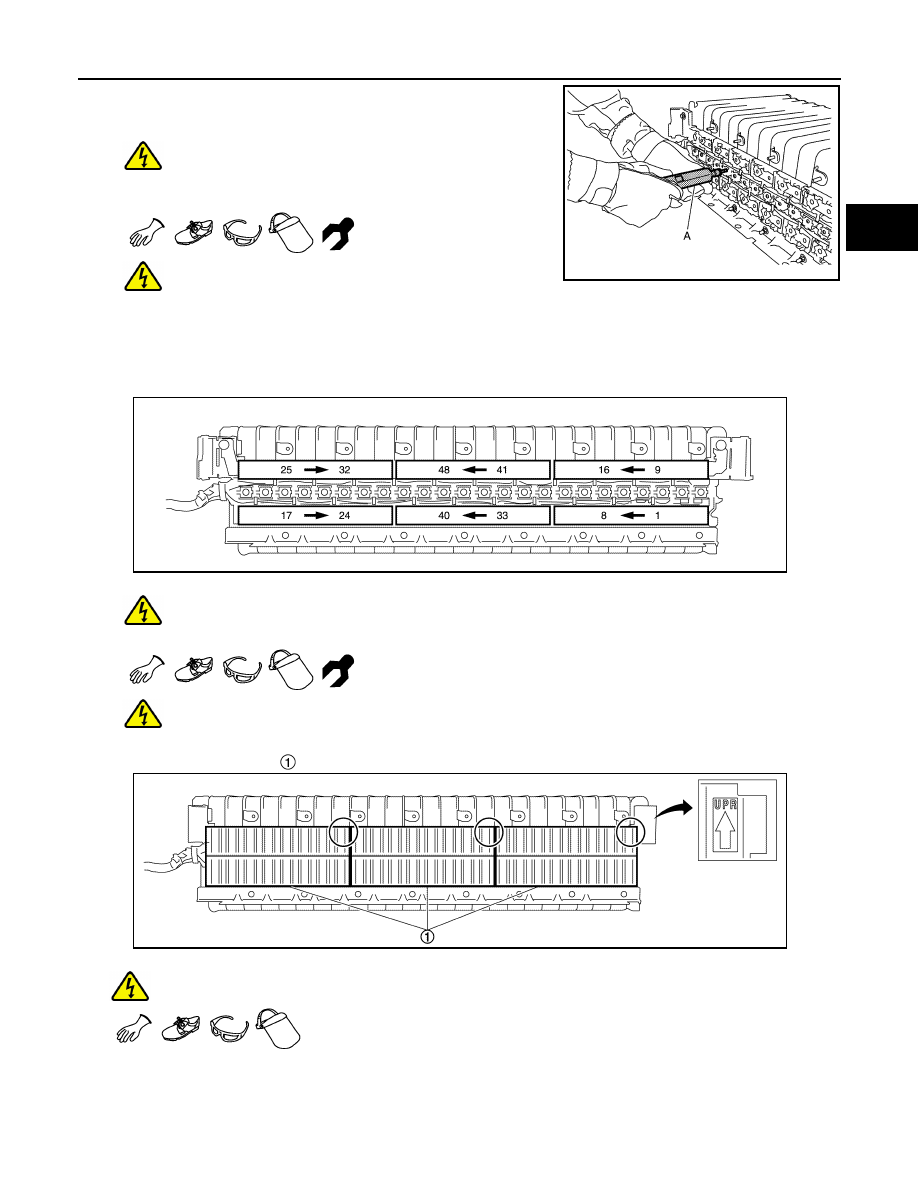

c. Tighten the module terminal mounting bolts in numerical order as shown in the figure.

• When tightening of 1 – 16 is completed, install the left-side bus bar cover.

• When tightening of 17 – 32 is completed, install the right-side bus bar cover.

• When tightening of 33 – 48 is completed, install the center bus bar cover.

DANGER:

•

There is the danger of electric shock caused by contact with the terminals. Be sure to wear

insulated protective gear and use insulated tools.

•

This work must not be performed by multiple operators because there is a risk of electric

shock if the operators contact one another.

d. Install the bus bar cover .

WARNING:

To prevent electric shock, wear insulated protective gear.

CAUTION:

• Be careful not to install with the top and bottom facing in the wrong directions.

• After installation, check that the mating is not skewed.

JPCIA0135ZZ

JPCIA0136ZZ

JPCIA0137ZZ