Nissan Leaf. Manual - part 491

LI-ION BATTERY

EVB-247

< UNIT DISASSEMBLY AND ASSEMBLY >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

WARNING:

To prevent electric shock, wear insulated protective gear.

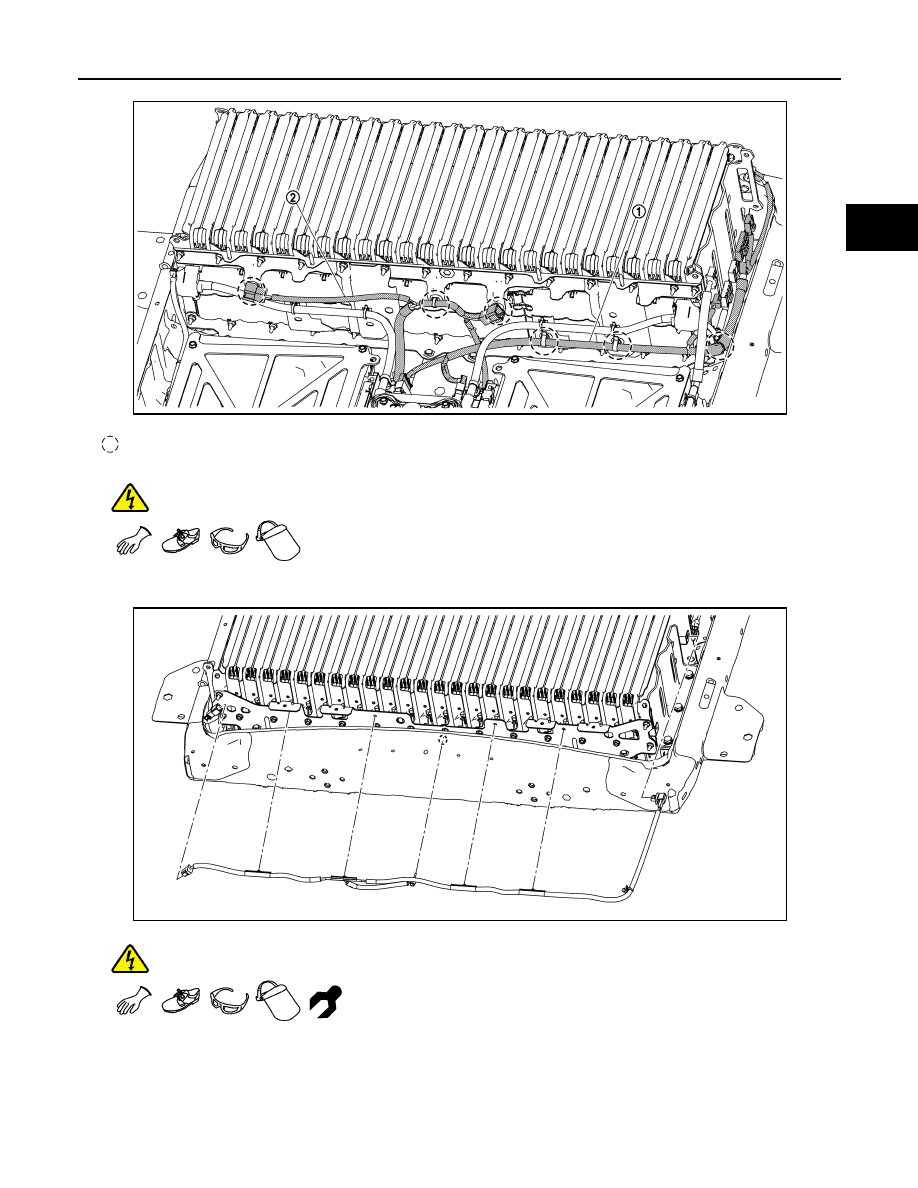

6. Install the battery temperature sensor harness (rear).

WARNING:

To prevent electric shock, wear insulated protective gear and use insulated tools.

NOTE:

Install the battery temperature sensor onto module No. MD12.

: Harness clip

JSCIA0769ZZ

JSCIA0647ZZ