Nissan Leaf. Manual - part 478

LI-ION BATTERY

EVB-195

< UNIT DISASSEMBLY AND ASSEMBLY >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

• If adhesive cutting particles enter the battery pack, clean (use of air blow is prohibited) when

assembling so that no particles remain on the battery module, bus bar, and high-voltage har-

ness.

• Operation must be performed by 2 persons. Be careful that the battery pack upper case does not

contact the battery module.

INSTALLATION

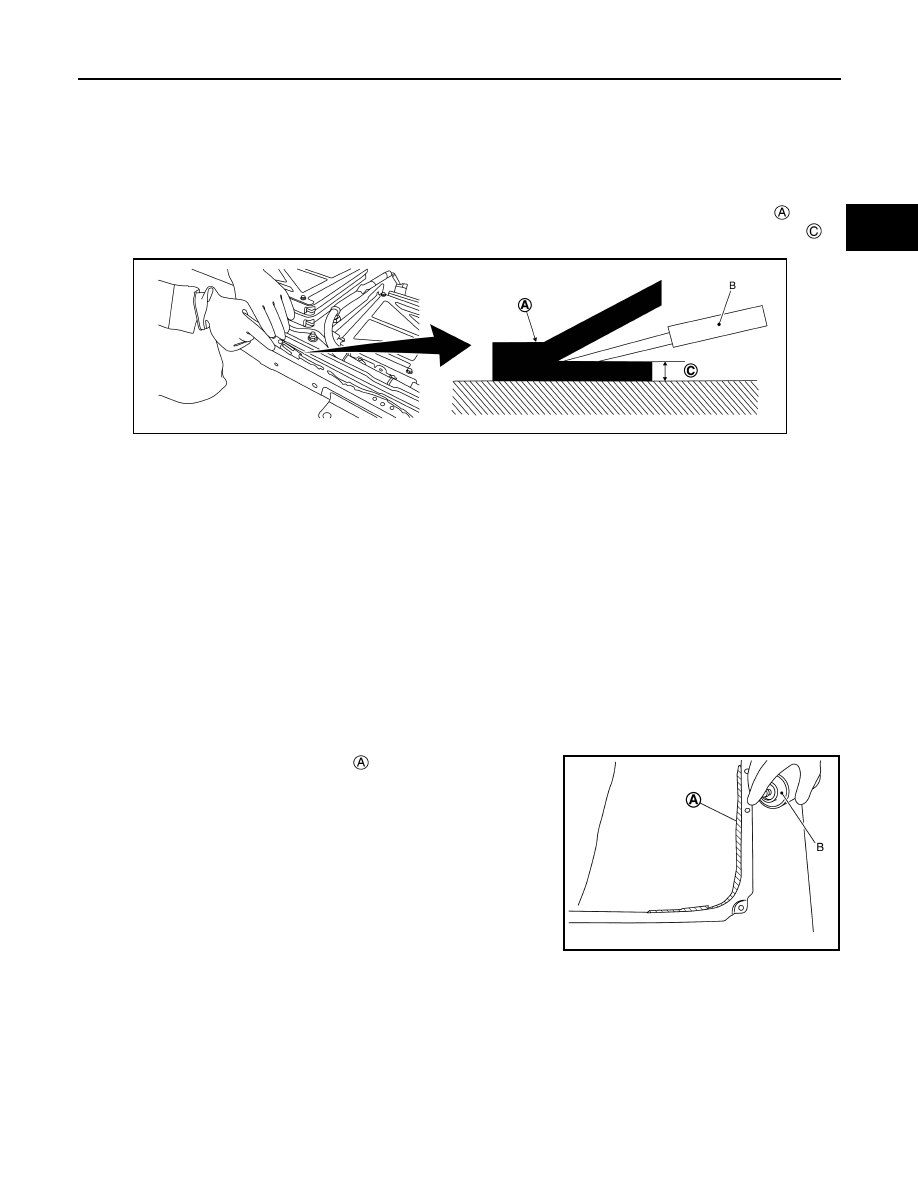

1. To remove remaining adhesive on the battery pack upper case and battery pack lower case , use a

scraper (B), and cut so that the surface is smooth, leaving approximately 1 – 2 mm (0.04 – 0.08 in) of

adhesive behind.

CAUTION:

• Because airtightness leakage is likely to occur, cut the seal in such a way that burrs are not pro-

duced.

• Be careful not to damage the paint sealant.

- If the paint sealant on a straight section is damaged in excess of the limit, the battery pack lower

case must be replaced. If the paint sealant damage is less than the limit, repair by applying

primer (adhesive primer: 999MP-43533PP).

- If the paint sealant damage on a corner is damaged, repair by applying primer (adhesive primer:

999MP-43533PP).

NOTE:

• Leave 1 – 2 mm (0.04 – 0.08 in) of adhesive so that the battery pack coating surface and paint sealant

are not damaged.

• Sharpen the blade of the scraper.

2. Repair scratches to the battery pack upper case by the following procedure.

a. Protect the seal with masking tape .

NOTE:

If primer surfacer (anti-corrosion primer) contacts the seal, the

adhesive strength is reduced.

b. Spray primer surfacer (anti-corrosion primer) (B) into the cracks

in the battery pack upper case.

Paint sealant damage limit:

Continuous length of undamaged section:

: 210 mm (8.27 in) or more

JSCIA0576ZZ

JSCIA0577ZZ