Nissan Leaf. Manual - part 469

P33EE BATTERY HEATER CONTROL SYSTEM

EVB-159

< DTC/CIRCUIT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

Check resistance of Li-ion battery heater.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace applicable Li-ion battery heater. Refer to

EVB-215, "LI-ION BATTERY HEATER : Disas-

.

5.

CHECK CONTINUITY OF LI-ION BATTERY HEATER AND BATTERY JUNCTION BOX

1. Disconnect Li-ion battery heater and battery junction box harness connector.

2. Check continuity Li-ion battery heater and battery junction box harness connector.

Is the inspection result normal?

YES

>> GO TO 6

NO

>> Repair harness or connector.

6.

CHECK CONTINUITY OF LI-ION BATTERY HEATER AND HEATER RELAY UNIT

1. Disconnect Li-ion battery heater and heater relay unit harness connector harness connector.

2. Check continuity Li-ion battery heater and heater relay unit harness connector harness connector.

Is the inspection result normal?

YES

>> Replace heater relay unit. Refer to

EVB-221, "LI-ION BATTERY HEATER RELAY UNIT : Disas-

.

NO

>> Repair harness or connector.

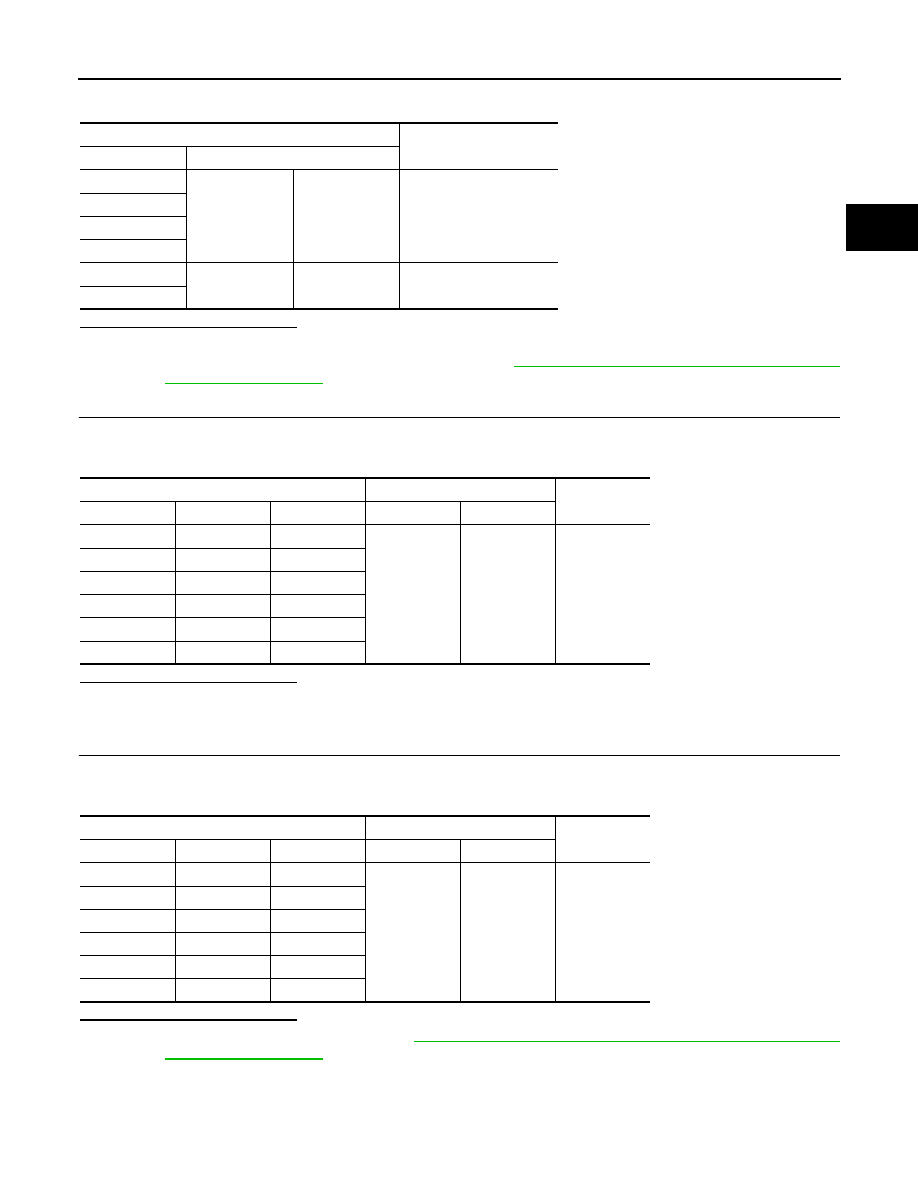

Li-ion battery heater

Resistance

Item

Terminal

LH 1

1

2

Less than 5,269

Ω

LH 2

RH 1

RH 2

RR 1

1

2

Less than 1,265

Ω

RR 2

Li-ion battery heater

Battery junction box

Continuity

Item

Connector

Terminal

Connector

Terminal

LH 1

LB19

2

LB25

15

Existed

LH 2

LB20

2

RH 1

LB23

2

RH 2

LB24

2

RR 1

LB21

2

RR 2

LB22

2

Li-ion battery heater

Heater relay unit

Continuity

Item

Connector

Terminal

Connector

Terminal

LH 1

LB19

1

LB18

11

Existed

LH 2

LB20

1

RH 1

LB23

1

RH 2

LB24

1

RR 1

LB21

1

RR 2

LB22

1