Nissan Leaf. Manual - part 352

BRM-32

< REMOVAL AND INSTALLATION >

BODY CONSTRUCTION

Rear Fender Hemming Process

INFOID:0000000010121696

1. A wheel arch is to be installed and hemmed over the left and right outer wheel houses.

2. In order to hem the wheel arch, it is necessary to repair any damaged or defaced parts around outer

wheel house.

CAUTION:

Ensure that the area that is to be glued around the outer wheelhouse is undamaged or defaced.

PROCEDURE OF THE HEMMING PROCESS

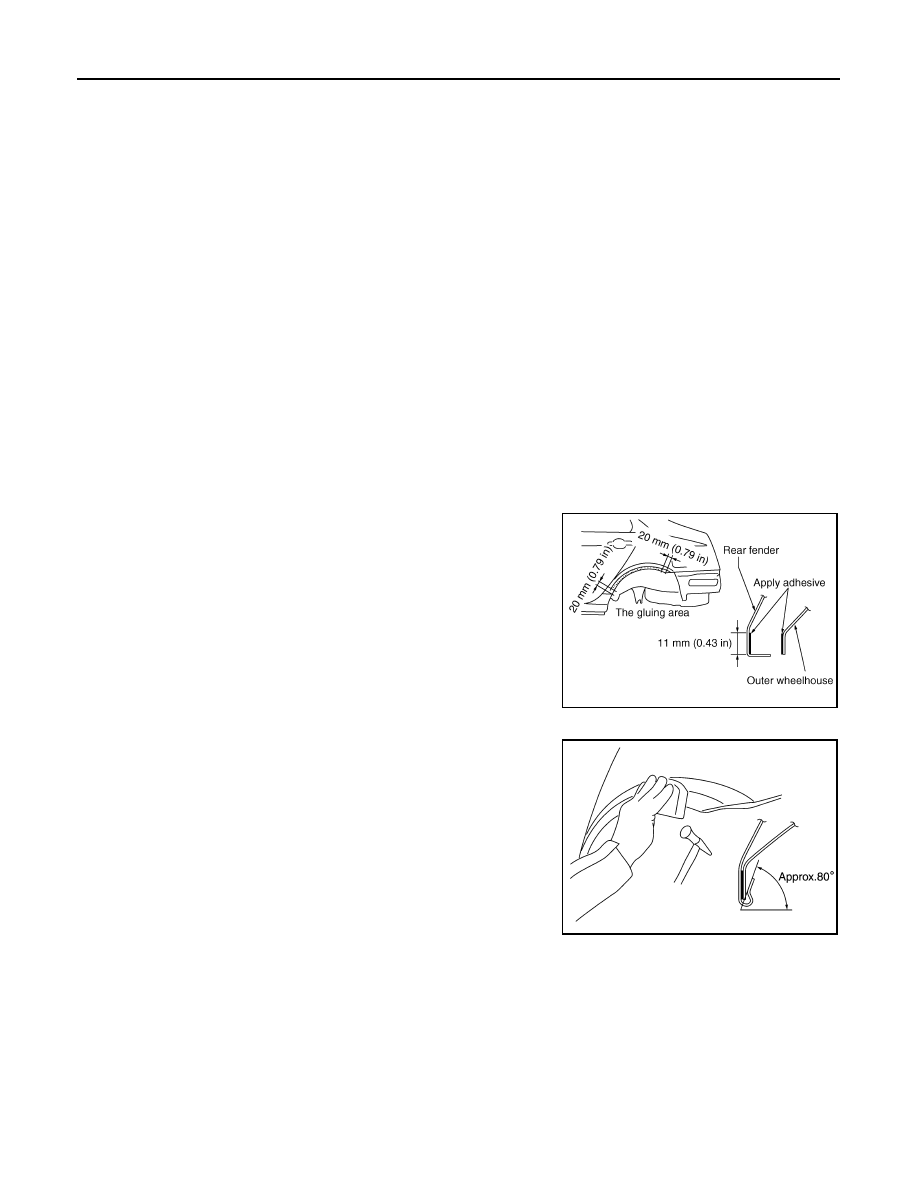

• Peel off old bonding material on the surface of the outer wheel-

house and clean thoroughly.

• Peel off a primer coat in the specified area where new adhesive is

to be applied on rear fender (the replacing part).

• Apply new adhesive to both specified areas of the outer wheel-

house and rear fender.

• Attach rear fender to the body of the car, and weld the required

part except the hemming part.

• Bend the welded part starting from the center of the wheel arch

gradually with a hammer and a dolly. (Also hem the end of the

flange.)

• Hemming with a hammer is conducted to an approximate angle of

80 degrees.

10. Lower dash

11. Lower front pillar hinge brace

12. Lower hinge plate

13. Inner front sill reinforcement

14. Inner sill

15. Front side member extension center

16. Front side member closing plate

17. Front outrigger

18. Front floor front

19. Lower front pillar reinforcement

20. Outer sill reinforcement

21. Outer sill brace

22. Front side member extension rear

23. Floor member extension

24. Center sill reinforcement

25. Roof

26. Center roof reinforcement

27. Roof member reinforcement

28. Inner center pillar

29. Center pillar seat belt anchor

30. Center pillar reinforcement

31. Center pillar hinge brace

32. Outer side roof rail

33. Front floor side

34. Rear side member closing plate

35. Rear side member reinforcement

36. Rear side member

37. Inner sill extension

38. Inner rear sill reinforcement

39. Outer rear wheelhouse extension

40. Inner rear wheelhouse

41. Outer rear wheelhouse

42. Rear fender extension

43. Back door stay bracket

44. Inner rear pillar

45. Rear roof rail brace

46. Inner rear pillar reinforcement

47. Rear pillar seat belt anchor

<Adhesive> 3M™ Automix™ Panel Bonding Adhe-

sive 08115 or equivalent

JSKIA0136GB

SIIA2245E