Nissan Leaf. Manual - part 323

BRC-82

< DTC/CIRCUIT DIAGNOSIS >

[WITH VDC]

C1111 ABS MOTOR, MOTOR RELAY SYSTEM

C1111 ABS MOTOR, MOTOR RELAY SYSTEM

DTC Logic

INFOID:0000000010120062

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn power switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1. Turn the power switch OFF

→ ON, and wait 30 seconds.

2. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

3. Stop the vehicle.

4. Turn the power switch OFF

→ ON.

CAUTION:

• Be sure to wait of 10 seconds after turning power switch OFF or ON.

• Set the vehicle to READY.

5. Repeat step 4 two or more times.

6. Perform “Self Diagnostic Result” of “ABS”.

Is DTC “C1111” detected?

YES

>> Proceed to

.

NO

>> Inspection End.

Diagnosis Procedure

INFOID:0000000010120063

Regarding Wiring Diagram information. Refer to

.

1.

CHECK CONNECTOR

1. Turn the power switch OFF.

2. Check the ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace error-detected parts, securely lock the connector, and GO TO 2.

2.

PERFORM SELF DIAGNOSTIC

With CONSULT

1. Turn the power switch OFF

→ ON, and wait 30 seconds.

2. Drive the vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

3. Stop the vehicle.

4. Turn the power switch OFF

→ ON.

CAUTION:

• Be sure to wait of 10 seconds after turning power switch OFF or ON.

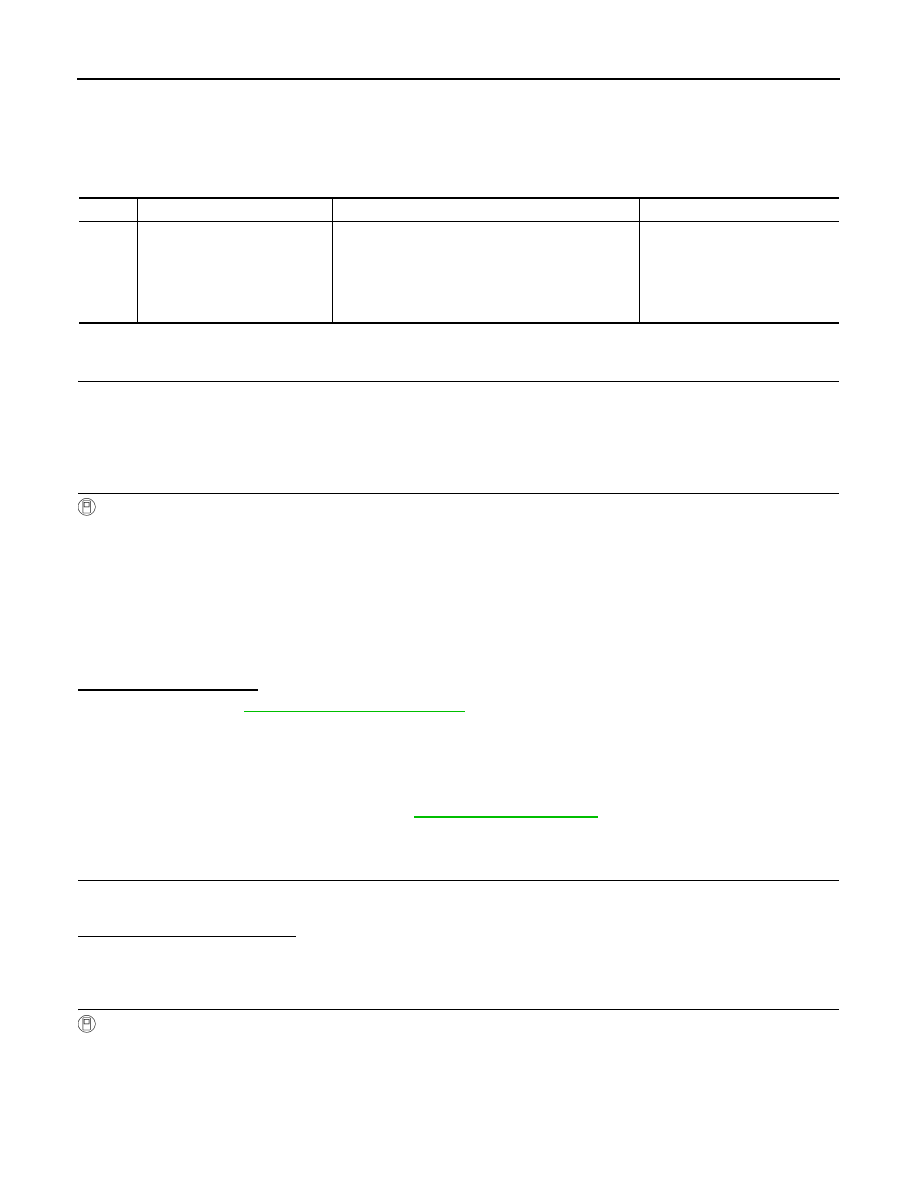

DTC

Display Item

Malfunction detected condition

Possible causes

C1111

PUMP MOTOR

When a malfunction is detected in motor or motor re-

lay.

• Harness or connector

• ABS actuator and electric unit

(control unit)

• Fusible link

• 12V battery power supply sys-

tem