Content .. 1289 1290 1291 1292 ..

Nissan Leaf. Manual - part 1291

ROAD WHEEL

WT-43

< PERIODIC MAINTENANCE >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

PERIODIC MAINTENANCE

ROAD WHEEL

Inspection

INFOID:0000000010120210

APPEARANCE

Check the road wheel for bend, damage, crack or wear.

Wheel Balance Adjustment

INFOID:0000000010120211

BALANCING WHEELS (ADHESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the road wheel. Using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean all traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

CAUTION:

• DO NOT use center hole cone-type clamping machines to hold the wheel assembly during tire

removal/installation or balancing or damage to the wheel paint, cladding or chrome may result. Use

only rim-type or universal lug-type clamping machines to hold the wheel assembly during servicing.

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and

skip Step 2 below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the center hole as a guide. Start the balancer machine.

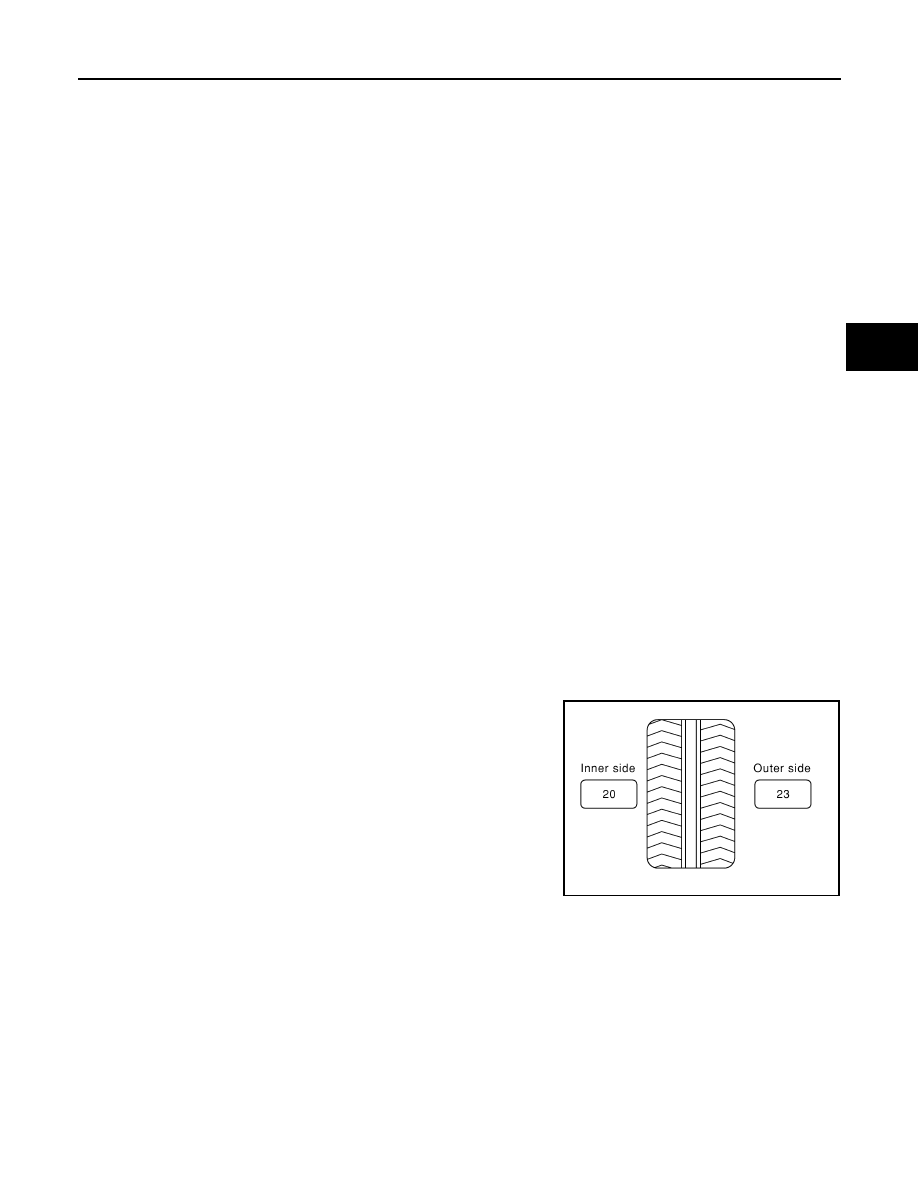

2. For balancer machines that only have a clip-on (rim flange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of or at the designated angle in relation to the road wheel.

a. Indicated imbalance value

× 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz)

× 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4

⇒ 35 g (1.23 oz)

37.5

⇒ 40 g (1.41 oz)

SMA054D