Content .. 1219 1220 1221 1222 ..

Nissan Leaf. Manual - part 1221

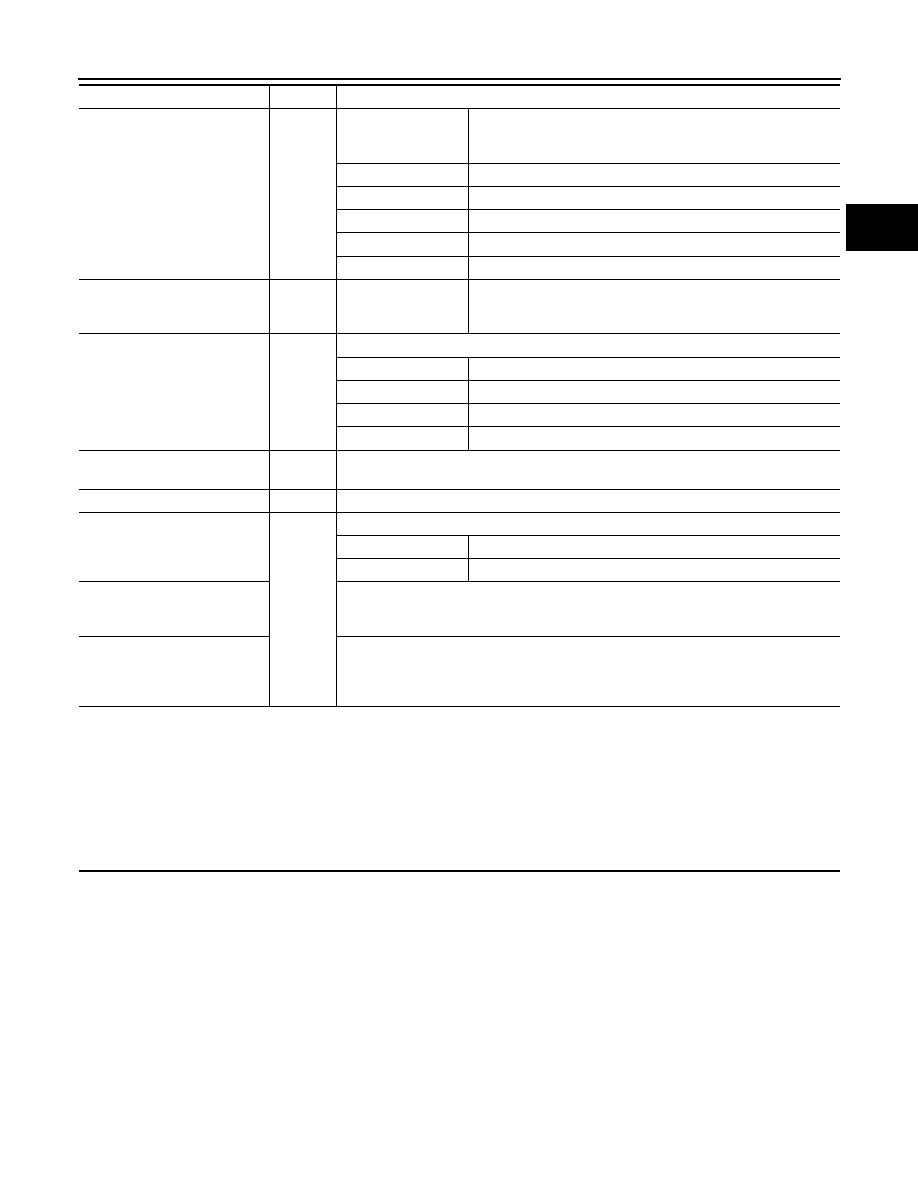

DIAGNOSIS AND REPAIR WORK FLOW

VC-51

< BASIC INSPECTION >

D

E

F

G

H

I

J

K

L

M

A

B

VC

N

O

P

Quick charger

Q

Quick charger maker

Not applicable

Applicable

(

)

Location

Model number

Serial number

Setting

Others

EVSE

N

Manufacturer

Genuine

Other

(

)

Wall outlet

N

Not applicable Applicable

Location

Voltage

V

Breaker

A

Other information

Li-ion battery remaining energy

Q/N/O

Not applicable Applicable

(

)

Shift position/operation

R

P R N D ECO When operating (

⇒

)

Weather condition

R/Q/N/O

Not applicable Applicable

Weather

Temperature

°C (or °F)

Occurrence frequency

All the time Once Sometimes ( times in the past)

Others

(

)

Timing of recovery from mal-

function

POWER OFF Removal of 12V battery terminal Shift lever operation

During driving READY

Others

(

)

Question

Group

Information from the customer