Content .. 1189 1190 1191 1192 ..

Nissan Leaf. Manual - part 1191

P0A2D DRIVE MOTOR A TEMP SENSOR

TMS-45

< DTC/CIRCUIT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

TMS

N

O

P

NO

>> Repair or replace damaged parts.

4.

CHECK TRACTION MOTOR TEMPERATURE SENSOR CIRCUIT

1. Disconnect the traction motor harness connector.

2. Check the resistance between traction motor inverter vehicle side harness connector terminals and trac-

tion motor vehicle side harness connector terminals.

3. Check the harness for short.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace damaged parts.

5.

CHECK TRACTION MOTOR TEMPERATURE SENSOR

Check the traction motor temperature sensor. Refer to

TMS-45, "Component Inspection (Traction Motor Tem-

.

Is the inspection result normal?

YES

>> Replace the traction motor inverter. Refer to

TMS-103, "Removal and Installation"

.

NO

>> Replace the traction motor. Refer to

TMS-109, "Removal and Installation"

Component Inspection (Traction Motor Temperature Sensor)

INFOID:0000000010120929

1.

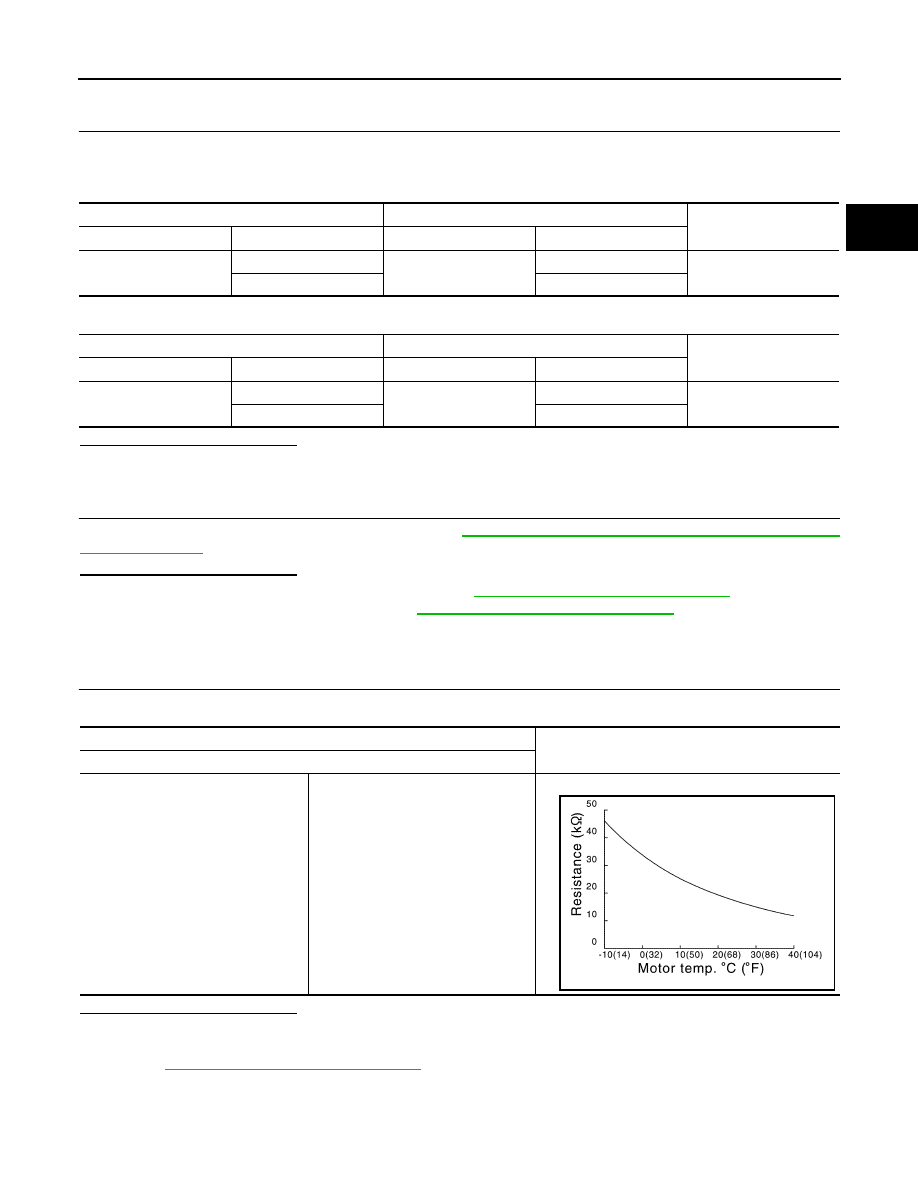

CHECK TRACTION MOTOR TEMPERATURE SENSOR

Check the resistance between traction motor connector terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace the traction motor due to malfunction in the traction motor temperature sensor. Refer to

TMS-109, "Removal and Installation"

.

Traction motor inverter

Traction motor

Resistance

Connector

Terminal

Connector

Terminal

F13

44

F14

4

1

Ω or less

45

3

Traction motor inverter

Traction motor

Resistance

Connector

Terminal

Connector

Terminal

F13

44

F14

3

100 k

Ω or more

45

4

Traction motor connector

Resistance

Terminal

3

4

Within

± 50% of temperature characteristics diagram

JPCIA0030GB