Content .. 1168 1169 1170 1171 ..

Nissan Leaf. Manual - part 1170

TM-86

< DTC/CIRCUIT DIAGNOSIS >

[ELECTRIC SHIFT]

P1897 ENCODER ERROR

P1897 ENCODER ERROR

DTC Logic

INFOID:0000000010119595

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, power switch OFF and wait for at least

10 seconds, then perform the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Set the vehicle to READY.

2. Shift the selector lever to N position and wait for 10 seconds or more.

3. Press the P position switch to shift to P position and wait for 10 seconds or more.

4. Check DTC.

Is “P1897” detected?

YES

>> Go to

NO-1 >> To check malfunction symptom before repair: Refer to

GI-53, "Intermittent Incident"

.

NO-2 >> Confirmation after repair: INSPECTION END

Diagnosis Procedure

INFOID:0000000010119596

1.

CHECK ENCODER POWER SUPPLY CIRCUIT

1. Power switch OFF.

2. Disconnect the parking actuator connector.

3. Check the voltage between parking actuator vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 4.

2.

CHECK HARNESS BETWEEN VCM AND ENCODER

1. Power switch OFF.

2. Disconnect the VCM connector.

3. Check the continuity between VCM vehicle side harness connector terminals and parking actuator vehicle

side harness connector terminals.

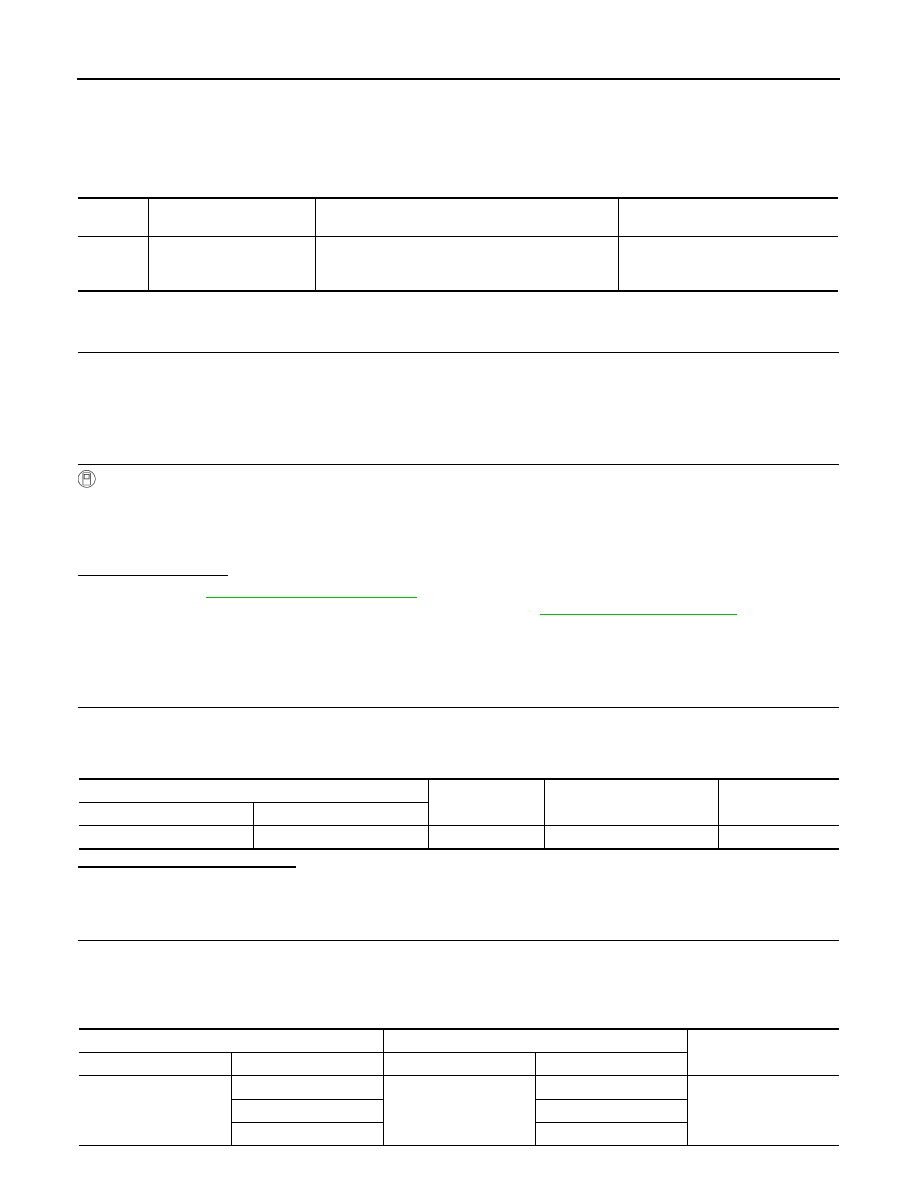

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible cause

P1897

ENCODER ERROR

(Encoder Error)

Encoder signals are not transmitted despite the ac-

tuation of parking actuator by the electric shift control

module.

• Encoder (Parking actuator)

• Harness or connectors

(Each circuit is open or shorted.)

Parking actuator

Ground

Condition

Voltage

(Approx.)

Connector

Terminal

F4

9

Ground

Power switch ON

5 V

VCM

Parking actuator

Continuity

Connector

Terminal

Connector

Terminal

E61

44

F4

3

Existed

45

5

56

8