Nissan Frontier D22. Manual - part 795

MA-34

ENGINE MAINTENANCE (VG33E AND VG33ER)

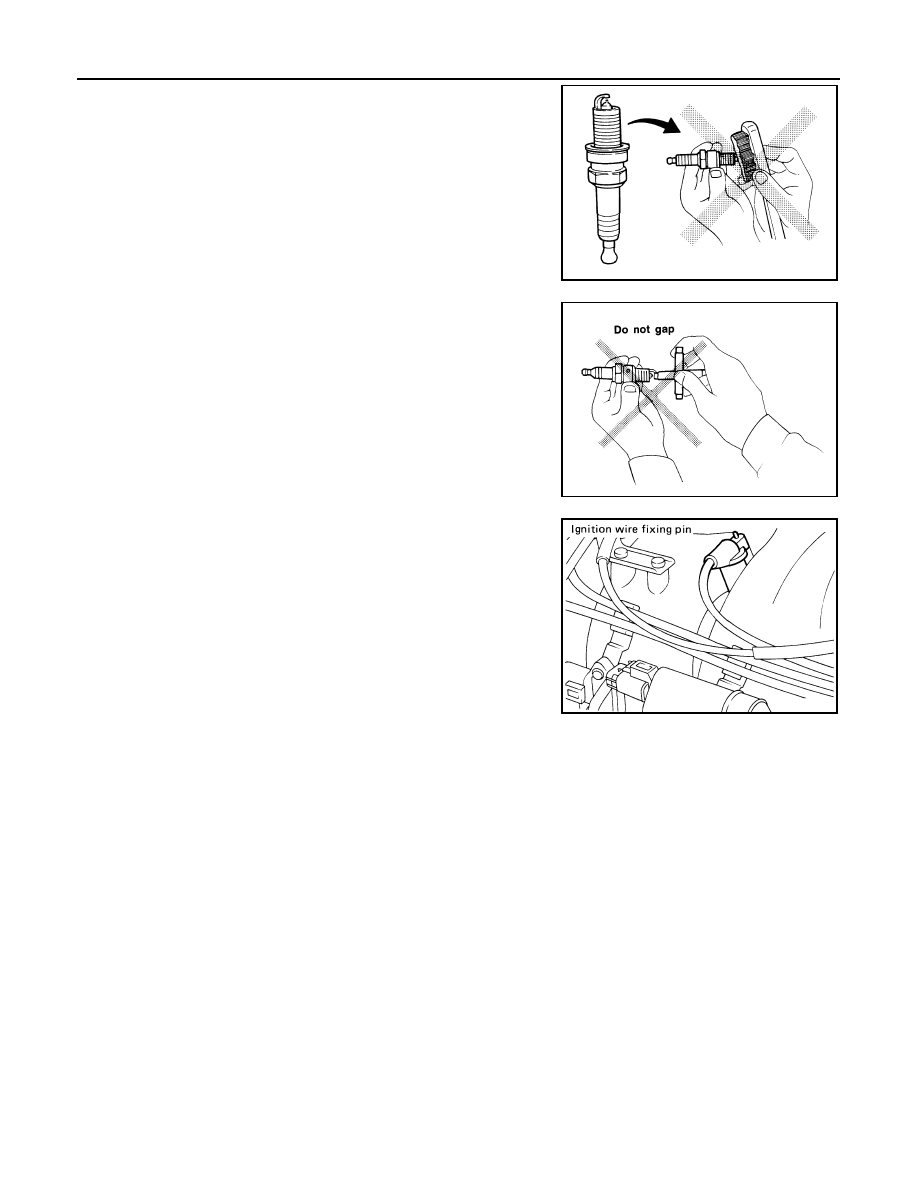

Do not use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between spark

plug change intervals.

When installing spark plugs to No. 2 and 4 cylinders, securely fit

each ignition wire mounting hole onto the ignition wire fixing pin.

Cleaner air pressure

Less than 588 kPa (6 kg/cm

2

, 85 psi)

Cleaning time

Less than 20 seconds

SMA773C

Spark plug gap (nominal)

1.1 mm (0.043 in)

SMA806C

Spark plug

: 20 - 29 N·m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

SMA213C