Nissan Frontier D22. Manual - part 647

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

EC-1691

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

3.

CHECK VACUUM CUT VALVE BYPASS VALVE OPERATION

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Remove vacuum cut valve and vacuum cut valve bypass valve as an assembly.

3.

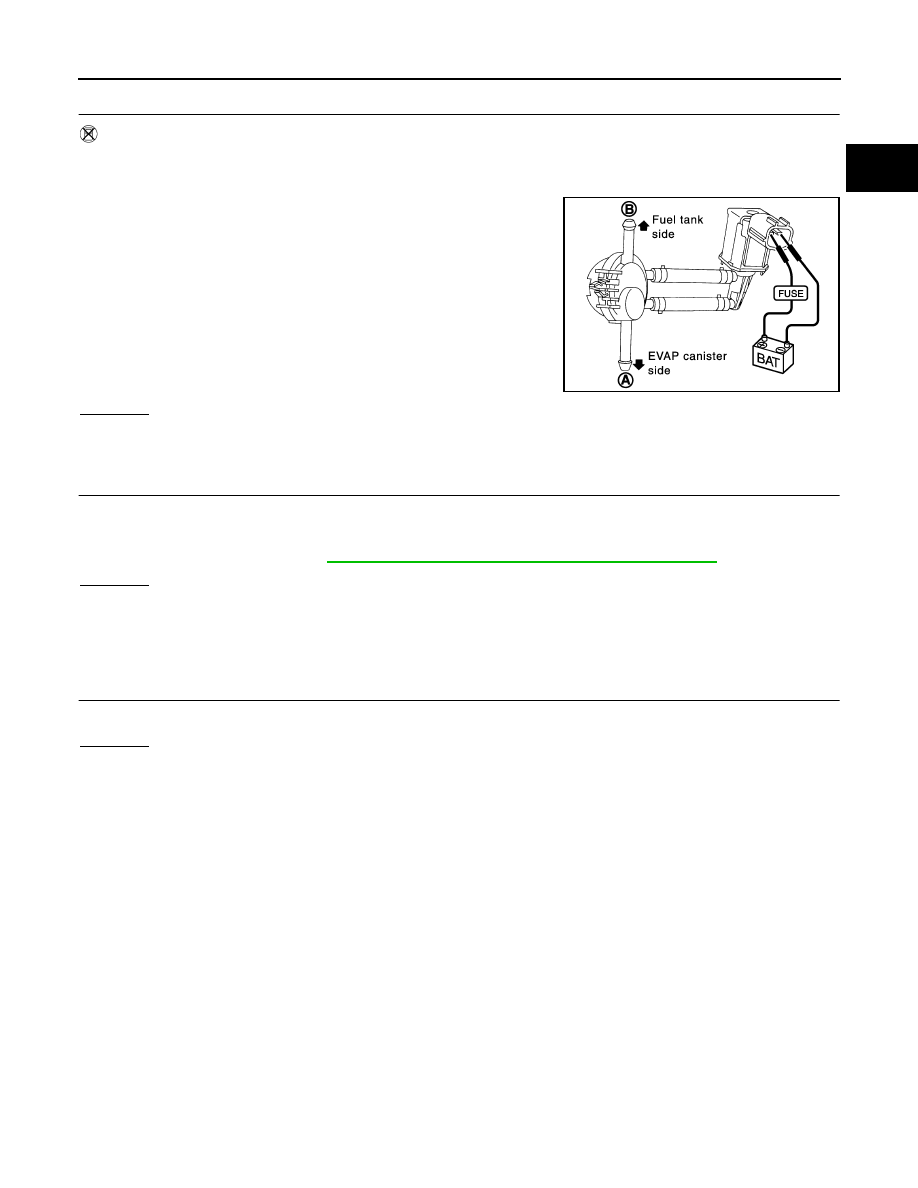

Apply vacuum to port A and check that there is no suction from

port B.

4.

Apply vacuum to port B and check that there is suction from port

A.

5.

Blow air in port B and check that there is a resistance to flow out

of port A.

6.

Disconnect vacuum cut valve bypass valve harness connector.

7.

Supply battery voltage to the terminal.

8.

Blow air in port A and check that air flows freely out of port B.

9.

Blow air in port B and check that air flows freely out of port A.

OK or NG

OK

>> GO TO 4.

NG

>> GO TO 5.

4.

CHECK EVAP PURGE LINE

1.

Check EVAP purge line between EVAP canister and fuel tank for clogging or disconnection.

2.

Check EVAP purge port of fuel tank for clogging.

3.

Check EVAP canister. Refer to

EC-1741, "EVAPORATIVE EMISSION LINE DRAWING"

.

OK or NG

OK

>> GO TO 8.

NG (Step 1)>>Repair it.

NG (Step 2)>>Clean EVAP purge port.

NG (Step 3)>>Replace EVAP canister.

5.

CHECK BYPASS HOSE

Check bypass hoses for clogging.

OK or NG

OK

>> GO TO 6.

NG

>> Repair or replace hoses.

PBIB0635E