Nissan Frontier D22. Manual - part 608

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-1535

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

8.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

1.

Disconnect ECM harness connector.

2.

Check harness continuity between ECM terminal 62 and EVAP control system pressure sensor terminal

2.

Refer to Wiring Diagram.

3.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO

TO

10.

NG

>> GO TO 9.

9.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors C1, M67

●

Harness connectors M59, F27

●

Harness for open or short between ECM and EVAP control system pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.

CHECK EVAP CANISTER VENT CONTROL VALVE

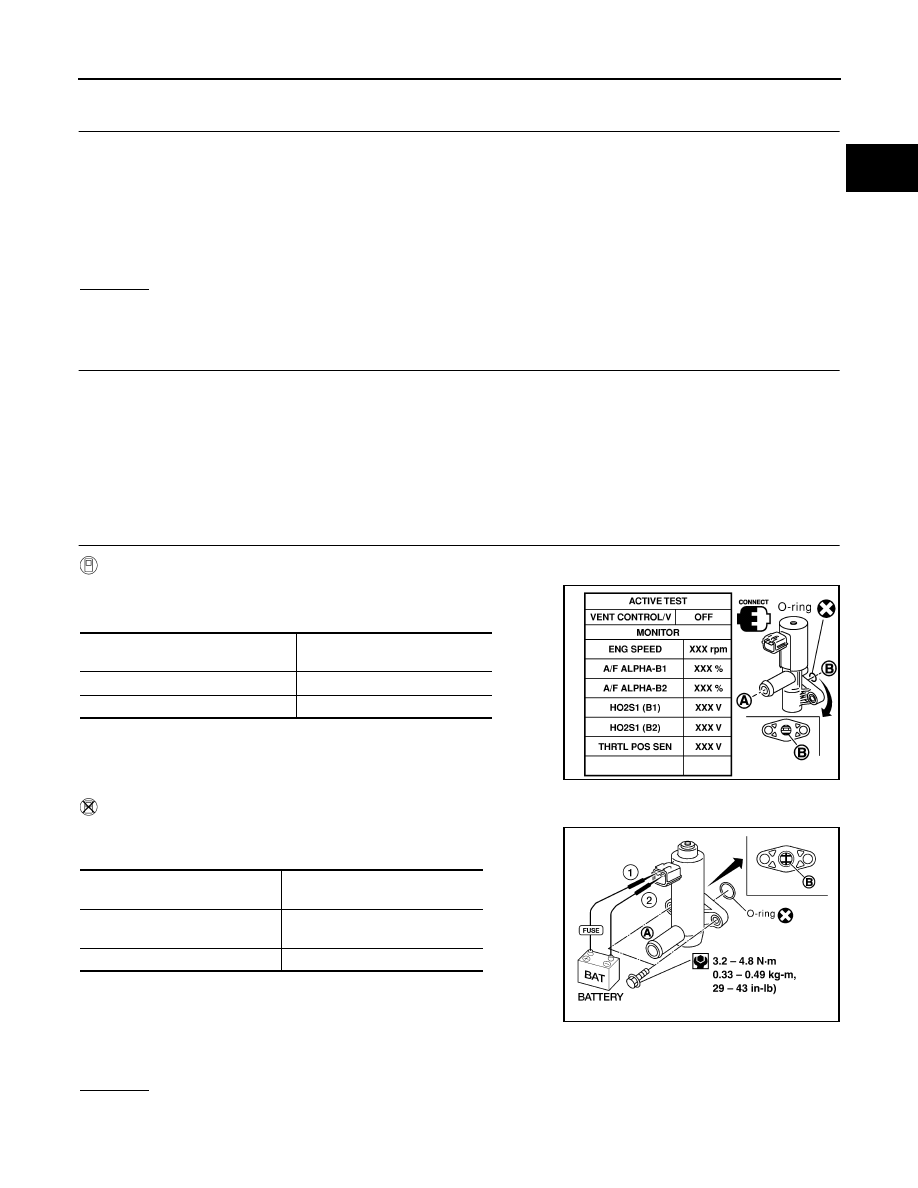

With CONSULT-II

1.

Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

2.

Check air passage continuity and operation delay time.

Operation takes less than 1second.

Without CONSULT-II

1.

Check air passage continuity and operation delay time under the

following condition.

Operation takes less than 1 second.

If NG or operation takes more than 1 second, clean valve using air

blower or replace as necessary.

If portion B is rusted, replace control valve.

Make sure new O-ring is installed properly.

OK or NG

OK

>> GO TO 11.

NG

>> Replace EVAP canister vent control valve.

Continuity should exist.

Condition VENT CONTROL/V

Air passage continuity between

A and B

ON

No

OFF

Yes

SEF013Z

Condition

Air passage continuity between A

and B

12V direct current supply

between terminals 1 and 2

No

OFF

Yes

BBIA0309E