Nissan Frontier D22. Manual - part 490

DTC P1402 EGR FUNCTION

EC-1063

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Diagnostic Procedure

UBS00DOH

1.

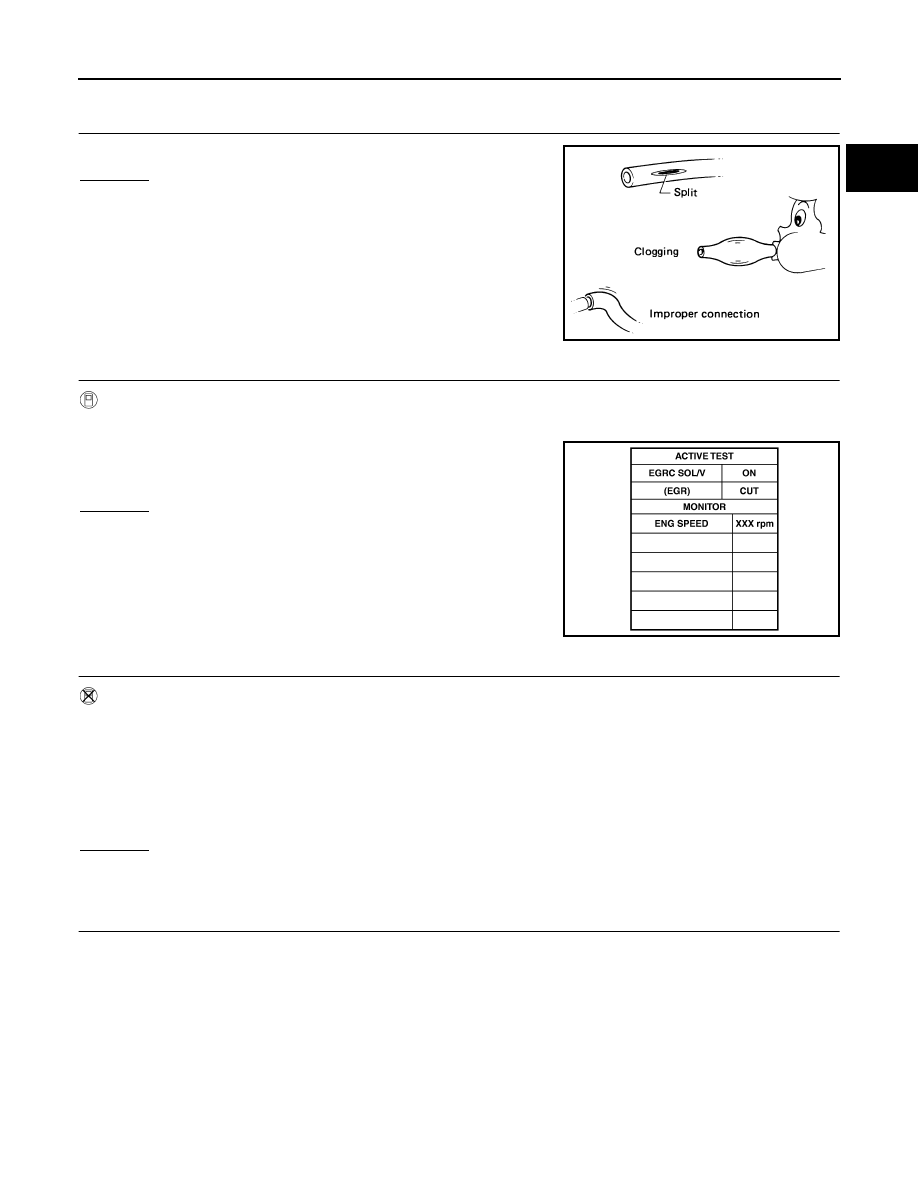

CHECK VACUUM HOSE

Check vacuum hose for clogging, cracks or improper connection.

OK or NG

OK (With CONSULT-II)>>GO TO 2.

OK (Without CONSULT-II)>>GO TO 3.

NG

>> Repair or replace vacuum hose.

2.

CHECK EGRC-SOLENOID VALVE CIRCUIT

With CONSULT-II

1.

Turn ignition switch ON.

2.

Turn EGRC-solenoid valve “ON” and “OFF” in “ACTIVE TEST”

mode with CONSULT-II and check operating sound.

Clicking noise should be heard.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

3.

CHECK EGRC-SOLENOID VALVE CIRCUIT

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Disconnect EGRC-solenoid valve harness connector.

3.

Turn ignition switch ON.

4.

Check operating sound of the solenoid valve when disconnecting and reconnecting EGRC-solenoid valve

harness connector. (The DTC or the 1st trip DTC for the EGRC-solenoid valve will be displayed, however,

ignore it.)

OK or NG

OK

>> GO TO 6.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors E43, M65

●

Harness connectors M59, F27

●

Fuse block (J/B) connector E49

●

10A fuse

●

Harness for open or short between fuse and EGRC-solenoid valve

●

Harness for open or short between ECM and EGRC-solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

SEF109L

SEF716Z