Nissan Frontier D22. Manual - part 411

DTC P0121 TP SENSOR

EC-747

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than the ECM terminals, such as the ground.

Diagnostic Procedure

UBS00DGZ

1.

INSPECTION START

Which malfunction (A or B) is duplicated?

A or B

A

>> GO TO 4.

B

>> GO TO 2.

2.

ADJUST THROTTLE POSITION SENSOR

Check the following items. Refer to

>> GO TO 3.

3.

CHECK INTAKE SYSTEM.

1.

Turn ignition switch OFF.

2.

Check the following for connection.

–

Air duct

–

Vacuum hoses

–

Intake air passage between air duct to intake manifold collector

OK or NG

OK

>> GO TO 4.

NG

>> Reconnect the parts.

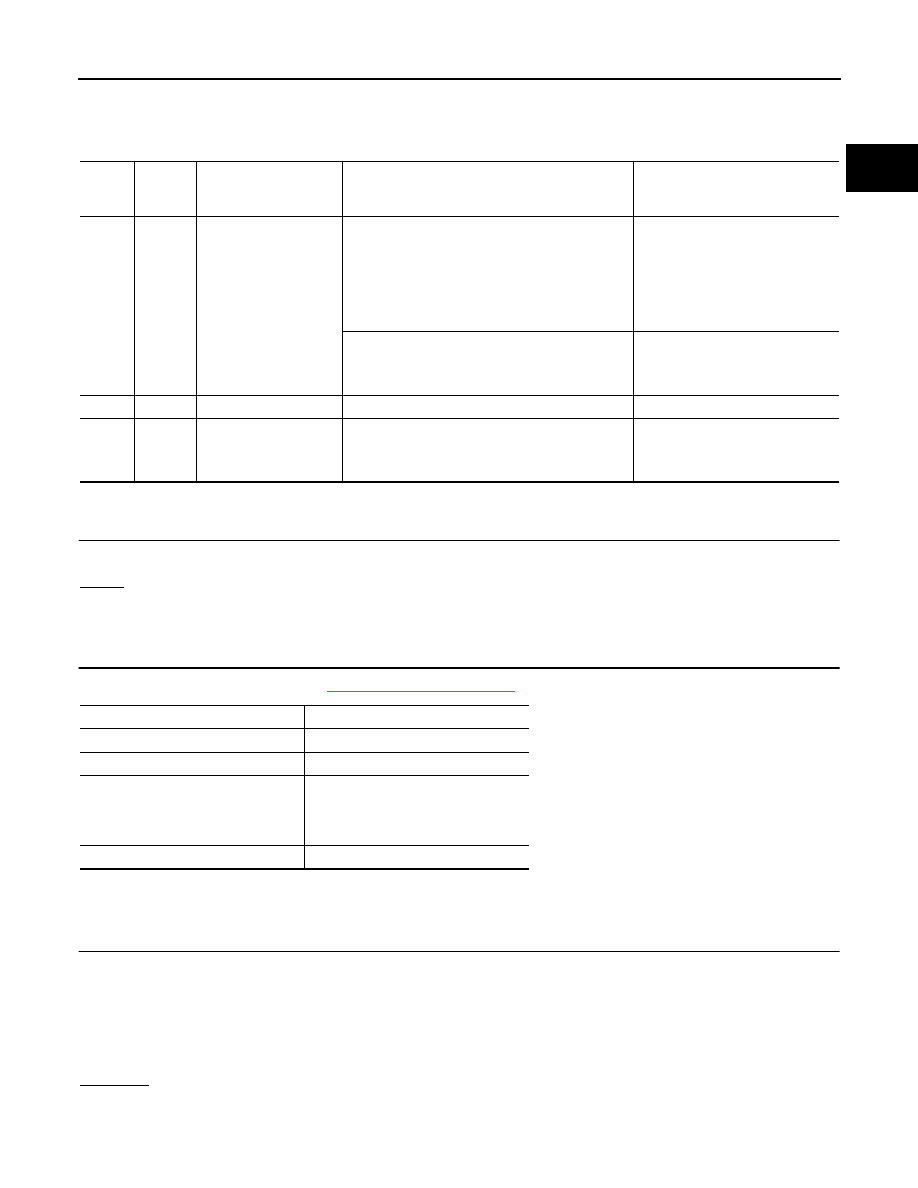

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

23

L

Throttle position sensor

[Engine is running]

●

Warm-up condition

●

More than -40.0 kpa (-300 mmHg, -11.81 inHg)

of vacuum is applied to the throttle opener with

a hand vacuum pump

●

Accelerator pedal is fully released

0.15 - 0.85V

[Ignition switch: ON]

●

Engine stopped

●

Accelerator pedal is fully depressed

3.5 - 4.7V

42

B/W

Sensor power supply

[Ignition switch: ON]

Approximately 5V

43

BR

Sensor ground

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 0V

Items

Specifications

Ignitions timing

10

± 5° BTDC

Base idle speed

700

± 50 rpm (in P or N position)

Closed throttle position switch idle

position adjustment

Feeler gauge thickness and switch

condition

0.3 mm (0.012 in): ON

0.4 mm (0.016 in): OFF

Target idle speed

750

± 50 rpm (in P or N position)