Nissan Frontier D22. Manual - part 387

TROUBLE DIAGNOSIS

EC-651

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

9.

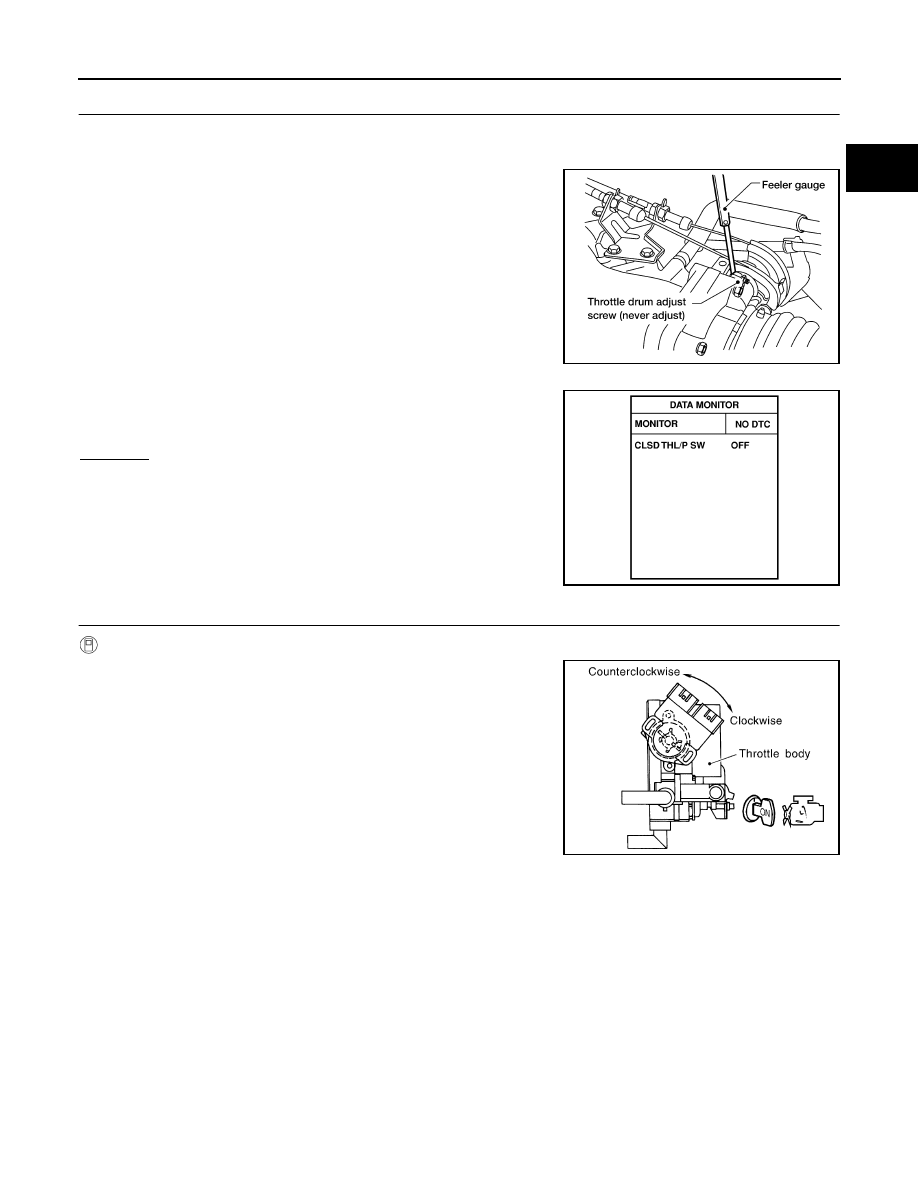

ADJUSTMENT CLOSED THROTTLE POSITION SWITCH IDLE POSITION-II

1.

Turn ignition switch ON.

2.

Select “TP SW/TP SEN IDLE POSI ADJ” in “WORK SUPPORT” mode.

3.

Insert 0.35 mm (0.0138 in) feeler gauge between throttle adjust

screw and throttle drum as shown in the figure.

4.

Open throttle valve and then close.

5.

Check “CLSD THL/P SW” signal.

“CLSD THL/P SW” signal should remain “OFF” when the

throttle valve is closed.

OK or NG

OK

>> GO TO 11.

NG

>> GO TO 10.

10.

ADJUSTMENT THROTTLE POSITION SWITCH IDLE POSITION-III

With CONSULT-II

Turn throttle position sensor body counterclockwise until “CLSD

THL/P SW” signal switches to “OFF”.

>> GO TO 11.

BBIA0419E

SEF305Y

SEF689W