Nissan Frontier D22. Manual - part 319

DTC P0460 FUEL LEVEL SENSOR

EC-379

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Diagnostic Procedure

UBS00D8F

1.

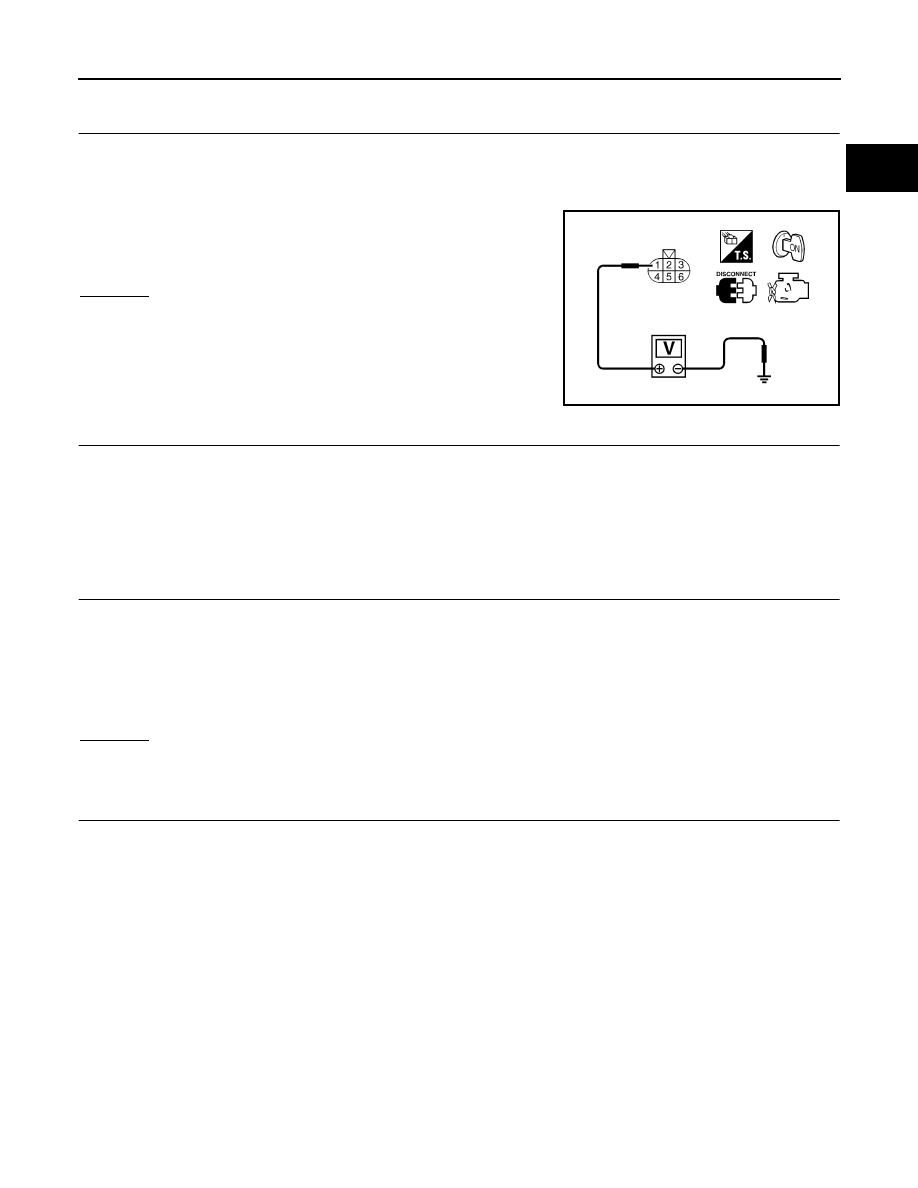

CHECK FUEL LEVEL SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect fuel level sensor unit and fuel pump harness connector.

3.

Turn ignition switch ON.

4.

Check voltage between fuel level sensor unit and fuel pump ter-

minal 1 and ground with CONSULT-II or a tester.

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 2.

2.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors M67, C1

●

Harness for open or short between combination meter and fuel level sensor until and fuel pump

>> Repair or replace harness or connectors.

3.

CHECK FUEL LEVEL SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Check harness continuity between fuel level sensor unit terminal 4 and body ground.

Refer to Wiring Diagram.

3.

Also check harness for short to power.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors M67, C1

●

Harness for open or short between fuel level sensor and body ground

>> Repair open circuit or short to power in harness or connectors.

Voltage

: Battery voltage

SEF863Z

Continuity should exist.