Nissan Frontier D22. Manual - part 305

DTC P0442 EVAP CONTROL SYSTEM

EC-323

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

18.

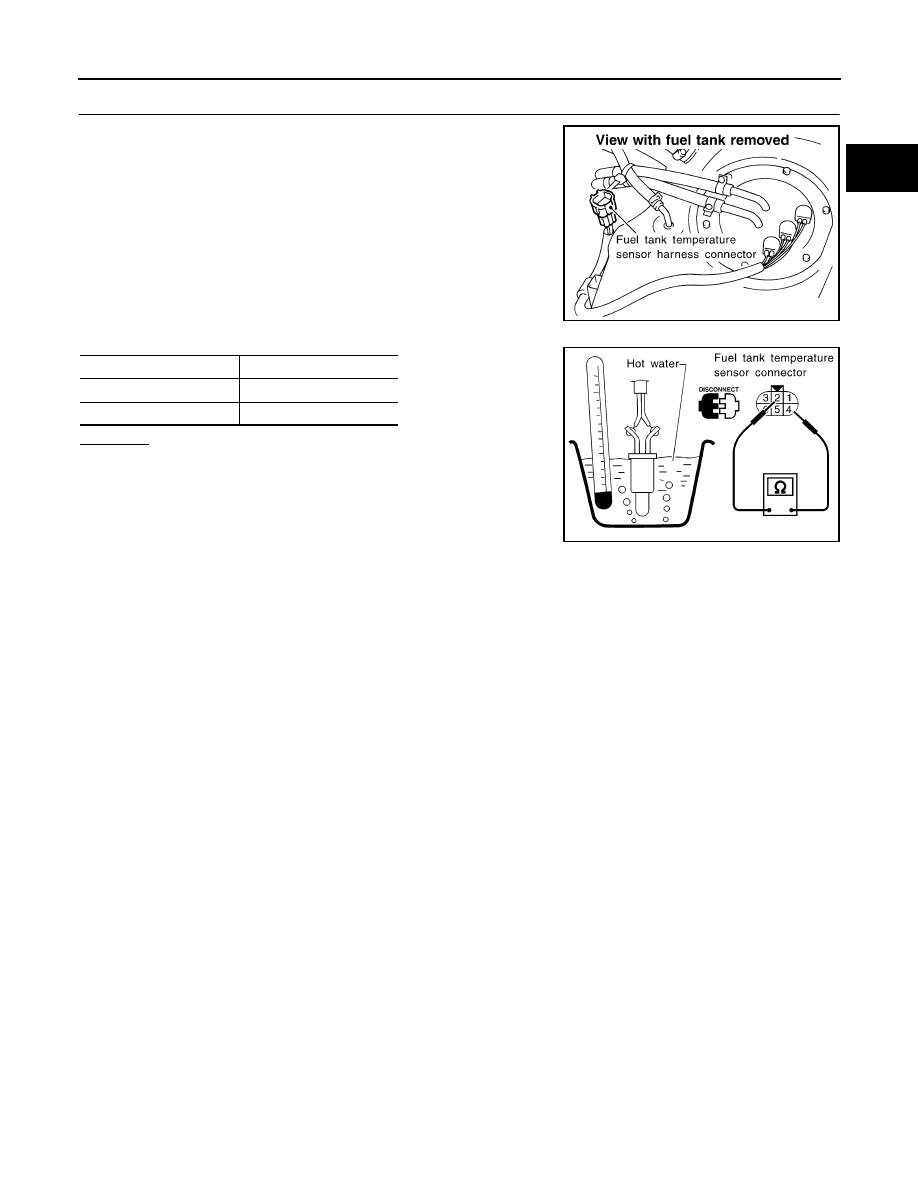

CHECK FUEL TANK TEMPERATURE SENSOR

Check resistance by heating with hot water or heat gun as shown in

the figure.

OK or NG

OK

>> GO TO 19.

NG

>> Replace fuel tank temperature sensor.

SEF334VA

Temperature

°C (°F)

Resistance k

Ω

20 (68)

2.3 - 2.7

50 (122)

0.79 - 0.90

SEF852Z