Nissan Frontier D22. Manual - part 244

TROUBLE DIAGNOSIS

EC-79

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

10.

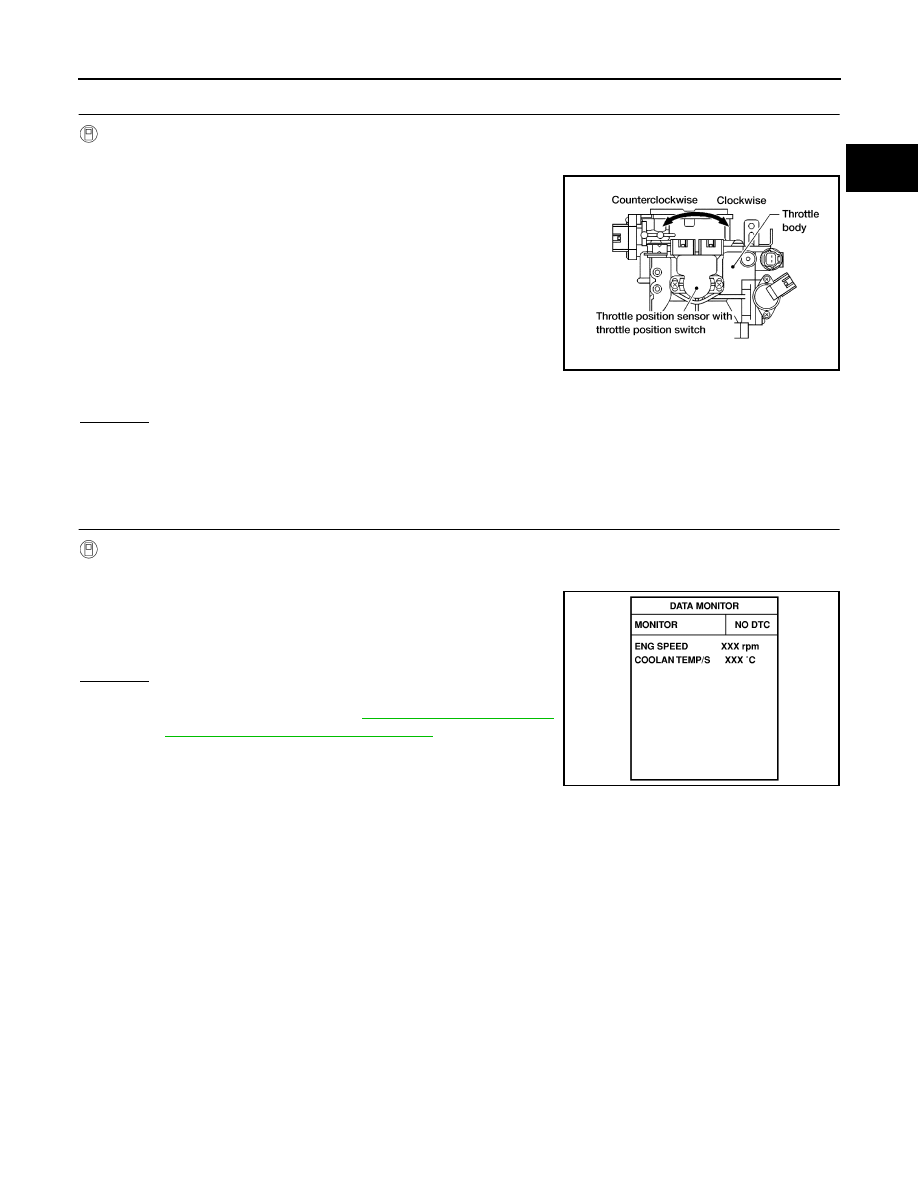

ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION-3

With CONSULT-II

1.

Temporarily tighten sensor body fixing bolts as follows.

–

Gradually move the sensor body clockwise and stop it

when “CLSD THL/P SW” signal switches from “OFF” to

“ON” when tightening sensor body fixing bolts.

2.

Make sure two or three times that the signal is “ON” when the

throttle valve is closed and “OFF” when it is opened.

3.

Remove 0.1 mm (0.004 in) feeler gauge then insert 0.3 mm

(0.012 in) feeler gauge.

4.

Make sure two or three times that the signal remains “OFF”

when the throttle valve is closed.

5.

Tighten throttle position sensor.

6.

Check “CLSD THL/P SW” signal again.

The signal remains “OFF” while closing throttle valve.

OK or NG

OK

>> 1. Remove 0.3 mm (0.012 in) feeler gauge.

2. GO TO 11.

NG

>> GO TO 8.

11.

CHECK TARGET IDLE SPEED

With CONSULT-II

1.

Start engine and warm it up to normal operating temperature.

2.

Select “ENG SPEED” in “DATA MONITOR” mode.

3.

Check idle speed.

OK or NG

OK

>> INSPECTION END

NG

>> Adjust idle speed. Refer to

Timing/Idle Mixture Ratio Adjustment"

. Inspection end

after adjust idle speed.

AEC872A

800

±50 rpm (in P or N position)

SEF174Y