Nissan Frontier D22. Manual - part 209

PRECAUTIONS

CO-19

[VG33E and VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

CO

Precautions for Liquid Gasket

EBS00GVP

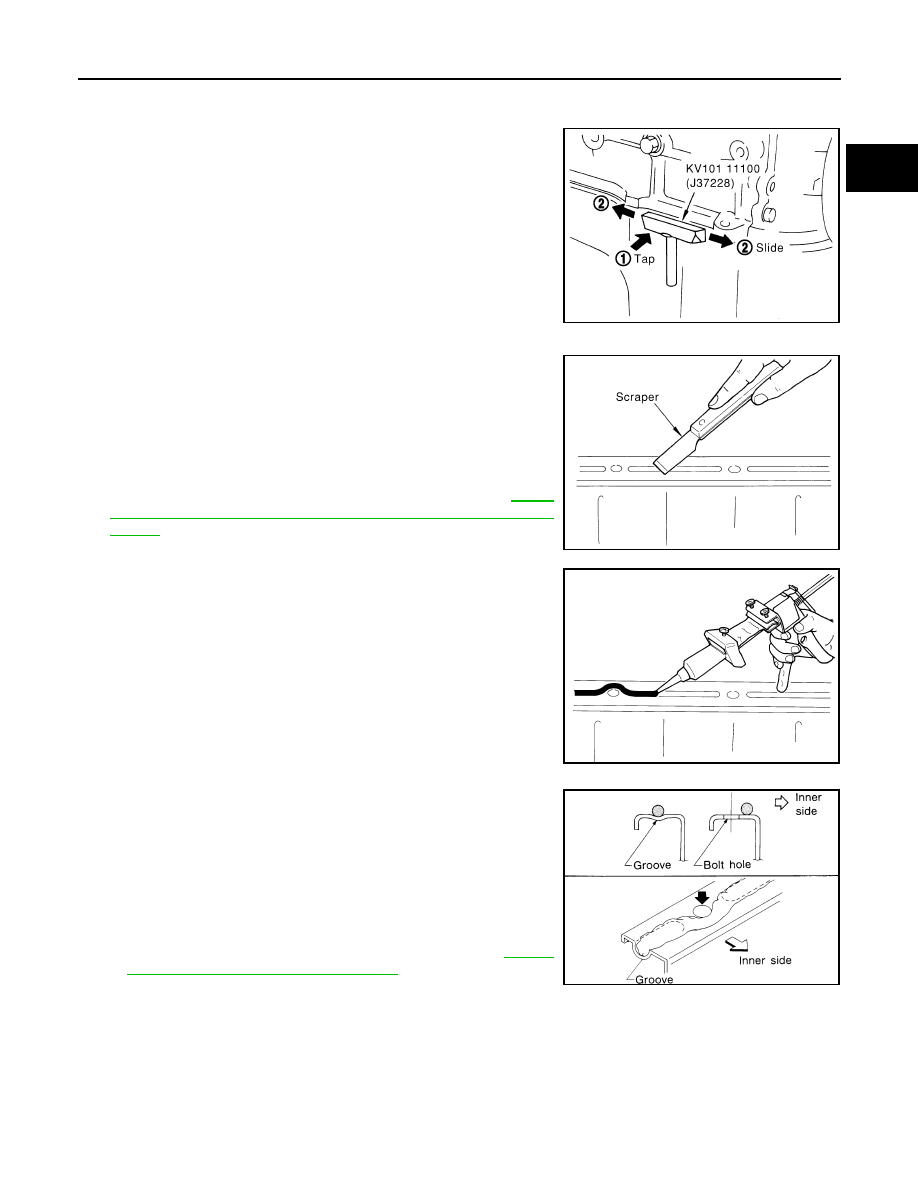

REMOVAL OF LIQUID GASKET

●

After removing the mounting bolts and nuts, separate the mating

surface using a seal cutter and remove the sealant.

CAUTION:

Be careful not to damage the mating surfaces.

●

In areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the sealant is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1.

Using a scraper, remove the old sealant adhering to the mating

surface.

●

Remove the sealant completely from the groove, mounting

bolts, and bolt holes.

2.

Clean the mating surface thoroughly to remove adhering mois-

ture, grease and foreign materials.

3.

Install the sealant tube into the tube presser.

Use Genuine Silicone RTV or equivalent. Refer to

"RECOMMENDED CHEMICAL PRODUCTS AND SEAL-

ANTS"

4.

Apply the sealant without breaks to the specified area with the

specified dimensions.

●

If there is a groove for the sealant application, apply the seal-

ant to the groove.

●

As for the bolt holes, normally apply the sealant inside the

holes. If specified, it should be applied outside the holes.

Make sure to read the instructions in this manual.

●

Within five minutes of sealant application, install the mating

component.

●

If the sealant protrudes, wipe it off immediately.

●

Do not retighten after the installation.

●

After 30 minutes or more have passed from the installation, fill

the engine with the correct oil and coolant. Refer to

"Recommended Fluids and Lubricants"

CAUTION:

If there are specific instructions in the service manual, observe them.

PBIC0002E

PBIC0003E

EMA0622D

SEM159F