Nissan Frontier D22. Manual - part 175

TROUBLE DIAGNOSIS

BRC-31

[ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

–:Not applicable

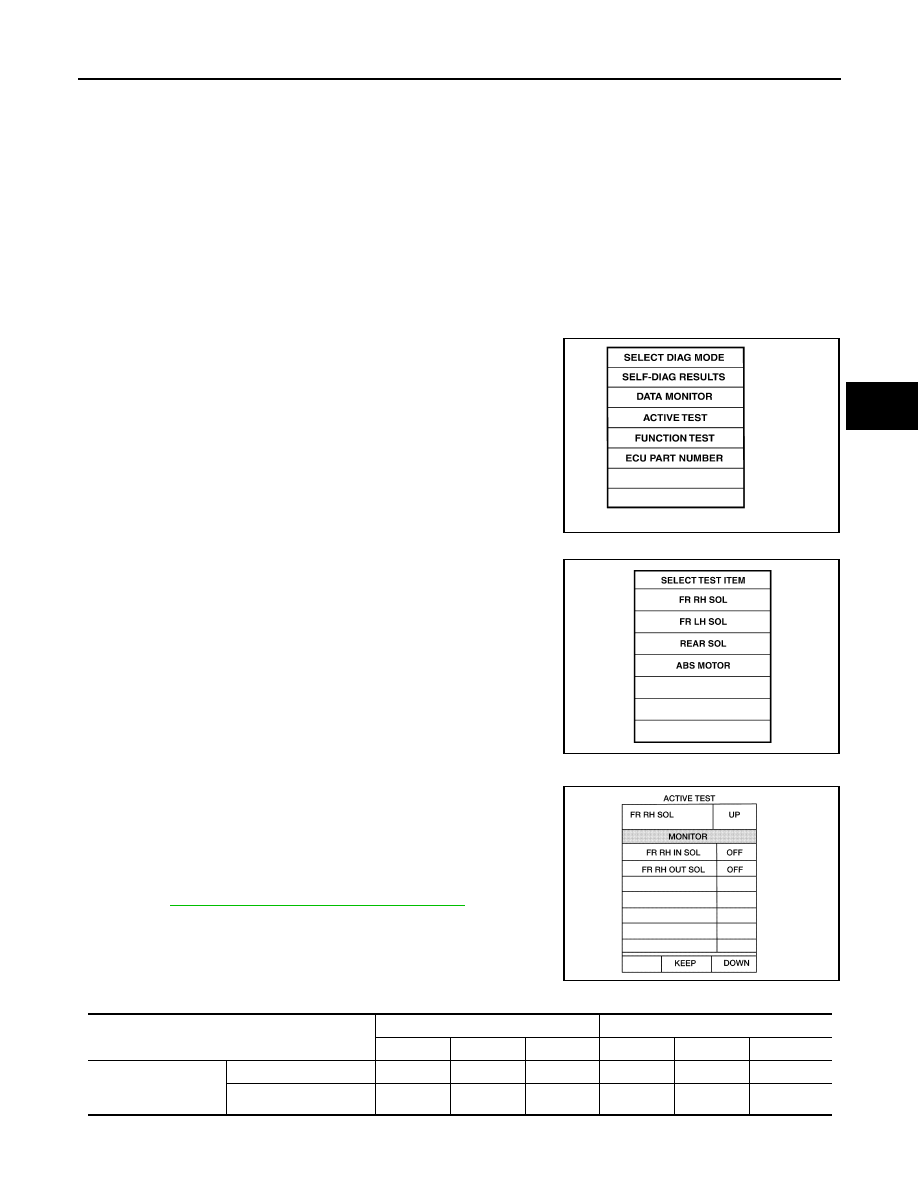

ACTIVE TEST

Operation Procedure

CAUTION:

●

Do not perform active test while driving the vehicle.

●

Make sure to completely bleed air from brake system.

●

Active test cannot be performed when ABS warning lamp is on.

1.

Connect the CONSULT-II connector to the data link connector and start the engine.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

2.

Touch

″START″ on the display.

3.

Touch

″ABS″ and ″ACTIVE TEST″.

4.

Test item selection screen is displayed.

5.

Touch necessary test item.

6.

Touch

″START″.

7.

Carry out the active test by touching screen key.

Solenoid Valve

1.

To perform active test of ABS functions, select major items for

each test item.

2.

For ABS solenoid valve, touch “UP”, “KEEP” and “DOWN”. For

ABS solenoid valve (ACT), touch “UP,” “ACTUATOR UP” and

“ACTUATOR KEEP”. Use screen monitor to check that solenoid

valve operates as shown in Solenoid Valve Operation Chart.

Refer to

BRC-88, "Solenoid Valve Operation Chart"

.

Solenoid Valve Operation Chart

WFIA0043E

LBR379

LFIA0180E

Operation

ABS solenoid valve

ABS solenoid valve (ACT)

UP

KEEP

DOWN

UP

ACT UP

ACT KEEP

FR RH SOL

FR RH ABS SOLE-

NOID (ACT)

FR RH IN SOL

OFF

ON

ON

OFF

OFF

OFF

FR RH OUT SOL

OFF

OFF

ON*

OFF

OFF

OFF