Nissan Xterra. Manual - part 685

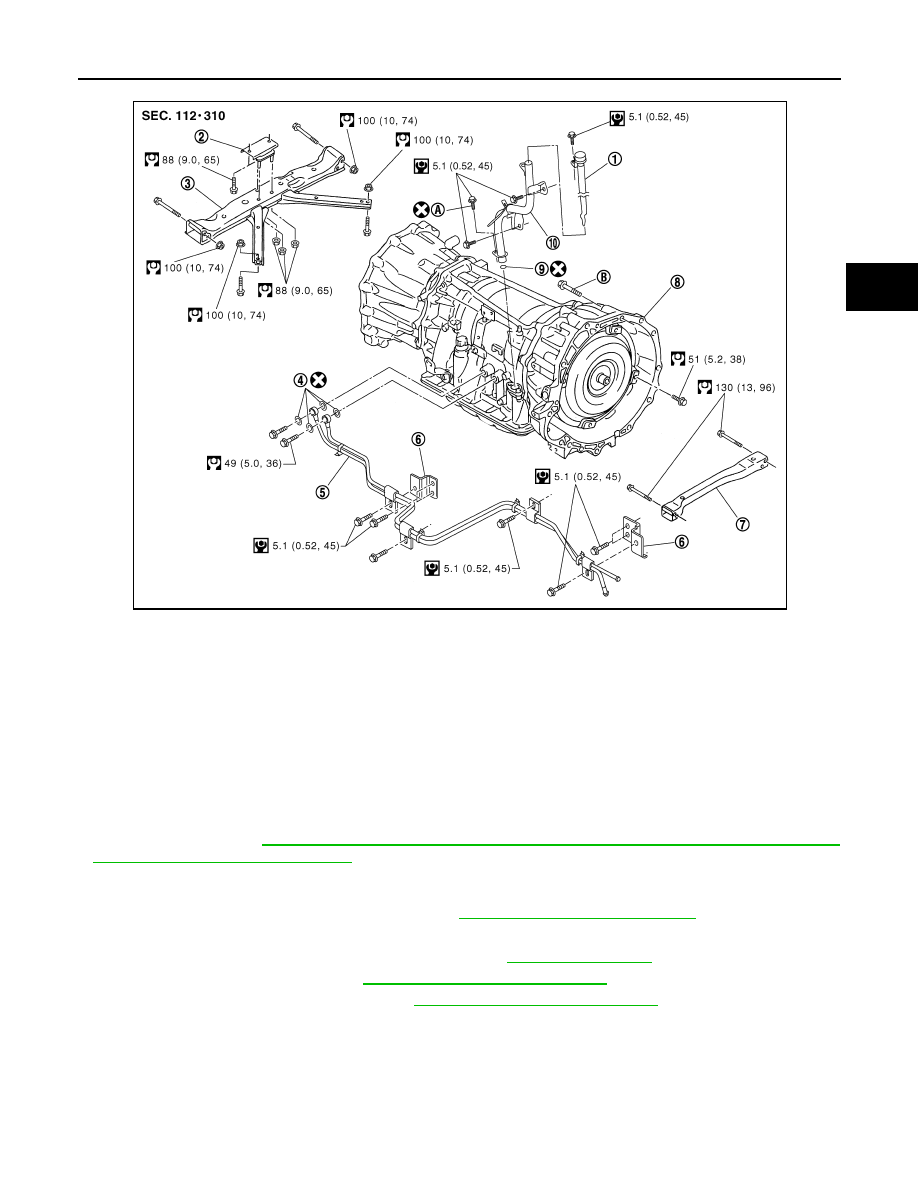

TRANSMISSION ASSEMBLY

TM-253

< UNIT REMOVAL AND INSTALLATION >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

CAUTION:

• Before replacing transmission assembly, perform "ADDITIONAL SERVICE WHEN TRANSMISSION

ASSEMBLY". Refer to

TM-77, "ADDITIONAL SERVICE WHEN REPLACING TRANSMISSION ASSEM-

BLY : Special Repair Requirement"

.

• When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS)

from the A/T assembly.

1. Disconnect the negative battery terminal. Refer to

PG-72, "Removal and Installation"

2. Remove the A/T fluid level gauge.

3. Remove the front wheel and tire assembly (LH). Refer to

4. Remove the mud flap (LH). Refer to

EXT-24, "Removal and Installation"

5. Remove the fender protector (LH). Refer to

EXT-22, "Removal and Installation"

1.

A/T fluid level gauge

2.

Insulator

3.

A/T crossmember

4.

Copper sealing washers

5.

A/T fluid cooler tube

6.

Bracket

7.

Front crossmember

8.

Transmission assembly

9.

O-ring

10. A/T fluid charging pipe

A. Self-sealing bolt

B. Refer to installation.

WCIA0574E