Nissan Xterra. Manual - part 427

EXT-26

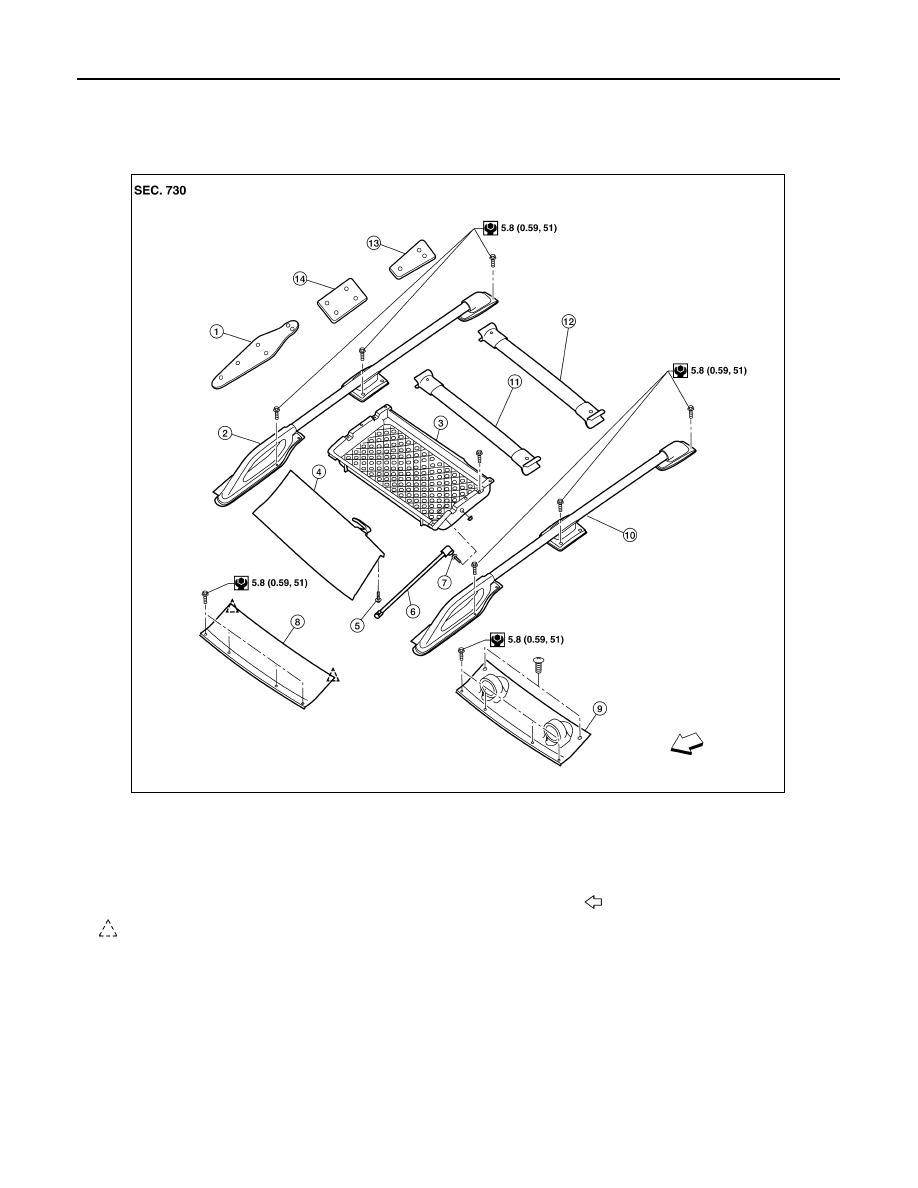

< REMOVAL AND INSTALLATION >

ROOF RACK

ROOF RACK

Removal and Installation

INFOID:0000000009483707

REMOVAL

1. Remove the front cover.

2. Remove storage bin and trim board as an assembly.

3. Remove front and rear crossbars (if equipped).

4. Remove side rails (LH/RH).

5. Remove front, center and rear stanchion gaskets.

INSTALLATION

Installation is in the reverse order of removal.

1.

Front stanchion gasket

2.

Side rail (RH)

3.

Storage bin (if equipped)

4.

Trim board

5.

Ball stud assembly

6.

Roof rack stay

7.

Ball stud assembly

8.

Front cover (except off-road)

9.

Front cover (off-road)

10. Side rail (LH)

11. Front crossbar (if equipped)

12. Rear crossbar (if equipped)

13. Rear stanchion gasket

14. Center stanchion gasket

Front

Clip C101

AWKIA1494GB