Nissan Xterra. Manual - part 371

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

ENGINE UNIT

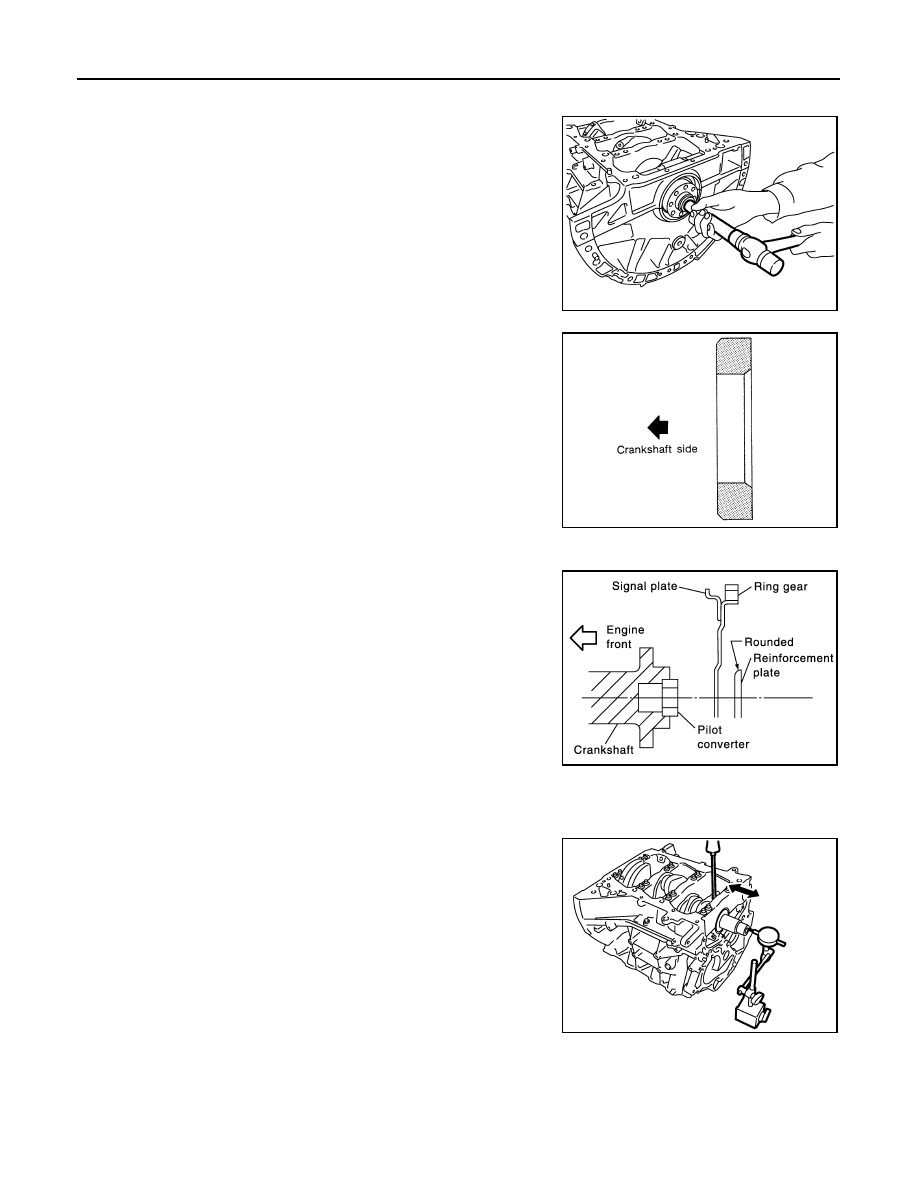

Pilot converter (A/T models)

• Install pilot converter.

• With drift of the following outer diameter, press-fit as far as it

will go.

• Press-fit pilot converter with its chamfer facing crankshaft as

shown.

Drive plate (A/T models)

• Install drive plate and reinforcement plate as shown.

• Hold ring gear using Ring Gear Stopper Tool.

• Tighten bolts crosswise over several times.

Inspection After Disassembly

INFOID:0000000009484493

CRANKSHAFT END PLAY

• Measure the clearance between thrust bearings and crankshaft

arm when crankshaft is moved fully forward or backward with dial

indicator.

• If the measured value exceeds the limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE

Pilot converter

: Approximately 33 mm

(1.30 in)

PBIC2947E

SEM537E

Tool number

: KV11105210 (J-44716)

PBIC0910E

Standard

: 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Limit

: 0.30 mm (0.0118 in)

PBIC2953E