Nissan Xterra. Manual - part 174

ENGINE COOLANT

CO-11

< PERIODIC MAINTENANCE >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

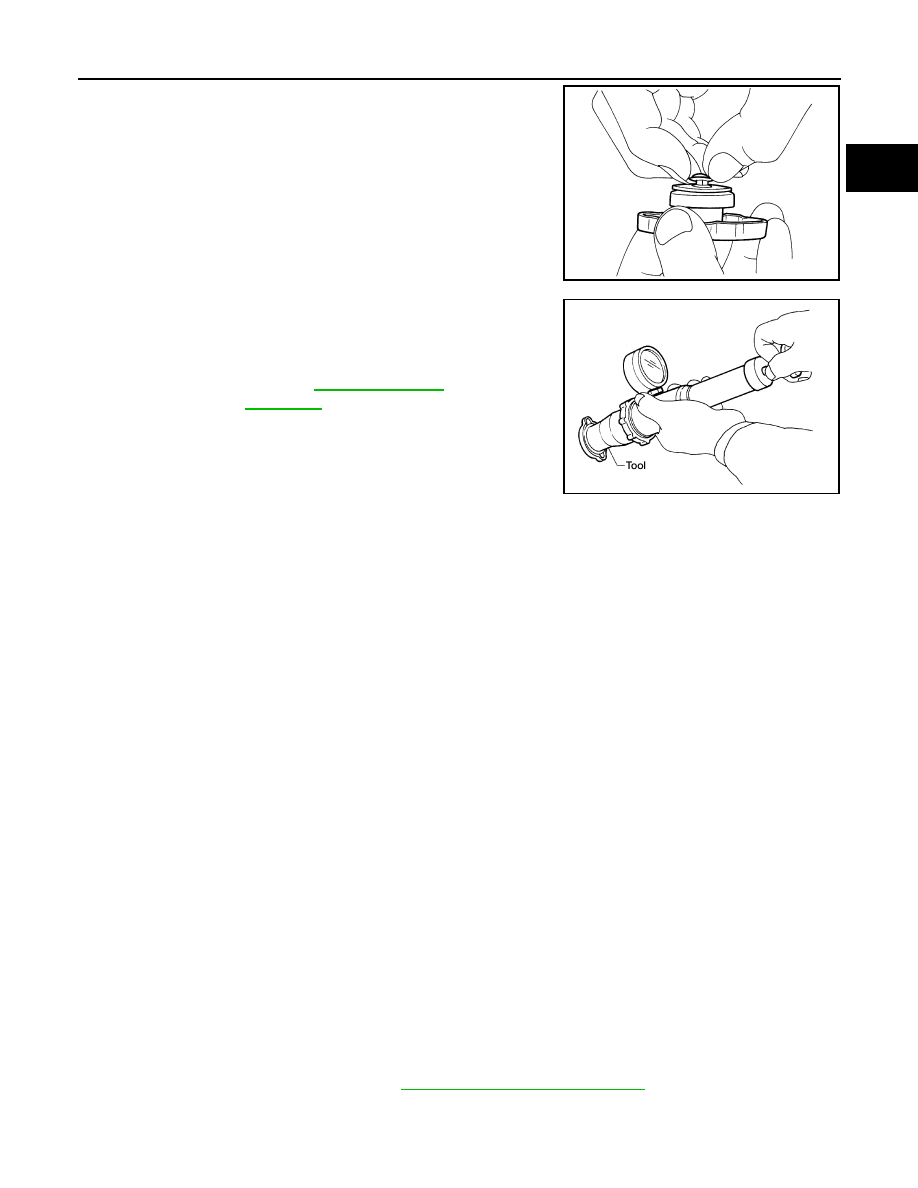

2. Pull the negative-pressure valve to open it and check that it

closes completely when released.

• Check that there is no dirt or damage on the valve seat of the

reservoir cap negative-pressure valve.

• Check that there are no abnormalities in the opening and clos-

ing conditions of the negative-pressure valve.

3. Check reservoir cap relief pressure using suitable tool and Tool.

NOTE:

• Apply engine coolant to the cap seal surface.

• Replace the reservoir cap if there is any damage in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the limit.

CHECKING RADIATOR CAP

Inspect the radiator cap.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

• Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or the

metal retainer.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

CAUTION:

• Be careful not to bend or damage the radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan shroud

and horns. Then tape the harness connectors to prevent water from entering.

1. Spray water to the back side of the radiator core using a side to side motion from the top down.

2. Stop spraying when debris no longer flows from radiator core.

3. Blow air into the back side of radiator core using a side to side motion from the top down.

• Use compressed air lower than 490 kPa (5 kg/cm

2

, 71 psi) and keep distance more than 30 cm (11.8 in).

4. Continue to blow air until no water sprays out.

5. Check for coolant leaks. Repair as necessary.

Changing Engine Coolant

INFOID:0000000009484582

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the radiator cap. Slowly turn it a

quarter of a turn to release built-up pressure. Carefully remove radiator cap by turning it all the way.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine under cover. Refer to

EXT-15, "Removal and Installation"

.

SMA967B

Tool number

: EG17650301 (J-33984-A)

Standard

: Refer to

.

WBIA0570E