Nissan Xterra. Manual - part 171

CL-18

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

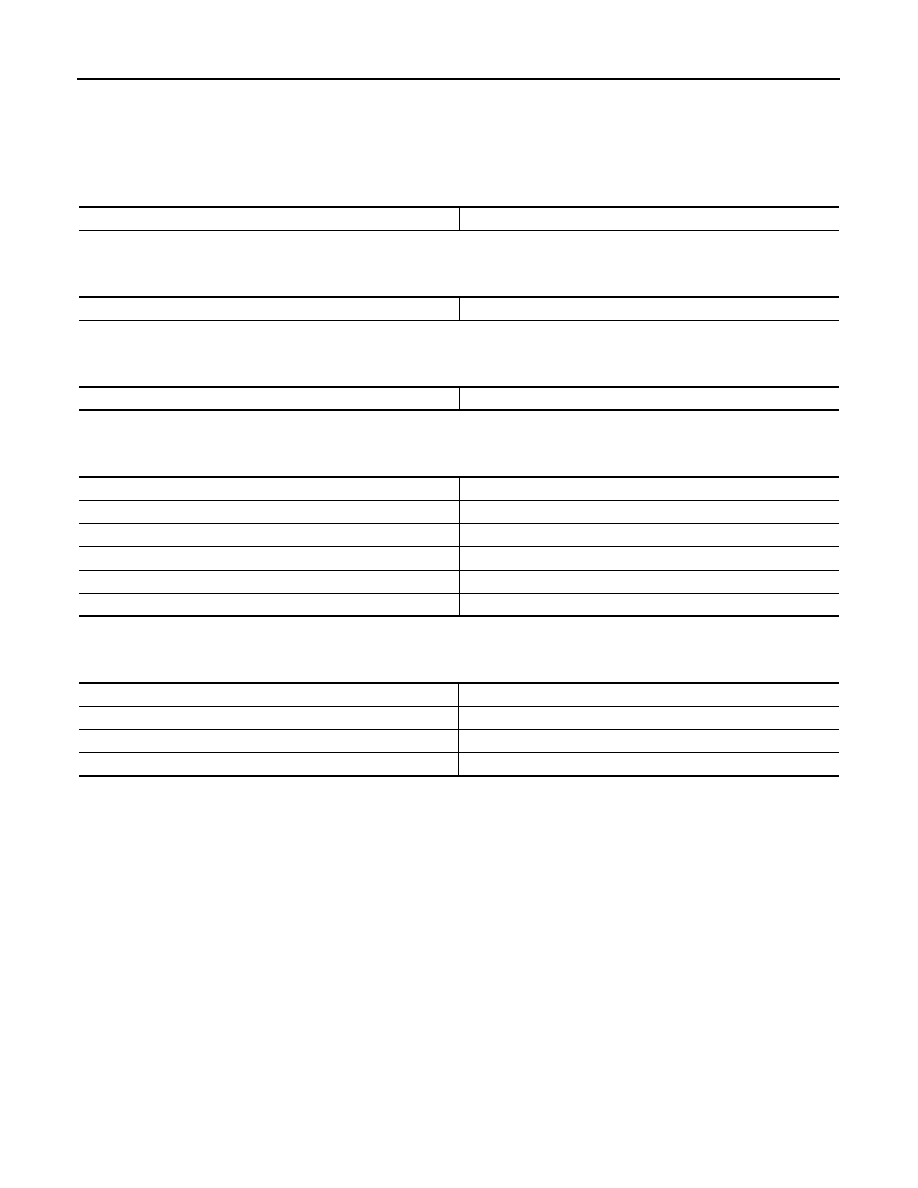

Clutch Control System

INFOID:0000000009483552

Clutch Master Cylinder

INFOID:0000000009483553

Unit: mm (in)

Clutch Operating Cylinder

INFOID:0000000009483554

Unit: mm (in)

Clutch Disc

INFOID:0000000009483555

Unit: mm (in)

Clutch Cover

INFOID:0000000009483556

Unit: mm (in)

Type of clutch control

Hydraulic

Inner diameter

15.87 (5/8)

Inner diameter

19.05 (3/4)

Engine model

VQ40DE

Model

260

Facing size (Outer dia.

× inner dia. × thickness)

260

× 190 × 3.2 (10.24 × 7.48 × 0.126)

Wear limit (depth to rivet head)

0.3 (0.012)

Runout limit/diameter of the area to be measured

1.0 (0.039) or less/250 (9.84) dia.

Maximum backlash of spline (at outer disc edge)

1.0 (0.039)

Engine model

VQ40DE

Set-load

8340 N (850 kg, 1875 lb)

Diaphragm spring lever height

44.0 - 46.0 (1.732 - 1.811)

Uneven limit of diaphragm spring toe height

0.7 (0.028)