Nissan Xterra. Manual - part 114

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

BRC-113

< UNIT REMOVAL AND INSTALLATION >

[TYPE 1]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

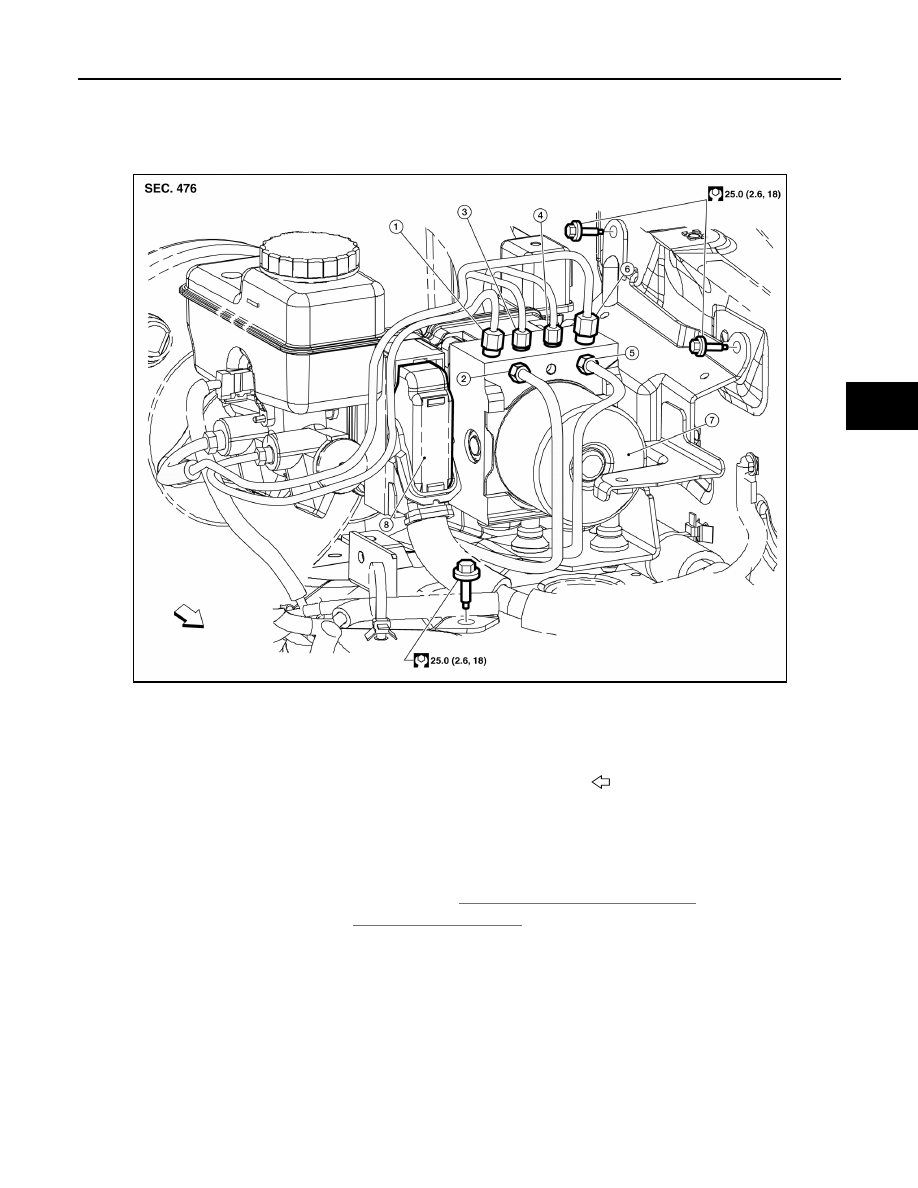

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and Installation

INFOID:0000000009482707

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Disconnect the negative battery terminal. Refer to

PG-72, "Removal and Installation"

2. Remove air cleaner case. Refer to

.

3. Disconnect the harness connector from the ABS actuator and electric unit (control unit).

4. Disconnect the brake tubes.

CAUTION:

• To remove the brake tubes, use a flare nut wrench to prevent the flare nuts and brake tubes from

being damaged.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

5. Remove three bolts, then remove the ABS actuator and electric unit (control unit) and bracket.

6. Remove the bolt and remove the bracket from the ABS actuator and electric unit (control unit).

INSTALLATION

1.

From master cylinder secondary side

18.2 N·m (1.9 kg-m, 13 ft-lb)

2.

To rear right disc brake

13.0 N·m (1.3 kg-m, 10 ft-lb)

3.

To rear left disc brake

13.0 N·m (1.3 kg-m, 10 ft-lb)

4.

To front right disc brake

13.0 N·m (1.3 kg-m, 10 ft-lb)

5.

To front left disc brake

13.0 N·m (1.3 kg-m, 10 ft-lb)

6.

From master cylinder primary side

18.2 N·m (1.9 kg-m, 13 ft-lb)

7.

ABS actuator and electric unit (control unit) 8.

Harness connector

Front

AWFIA0743GB