Nissan March K13. Manual - part 554

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RSU-3

< SYMPTOM DIAGNOSIS >

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

SYMPTOM DIAGNOSIS

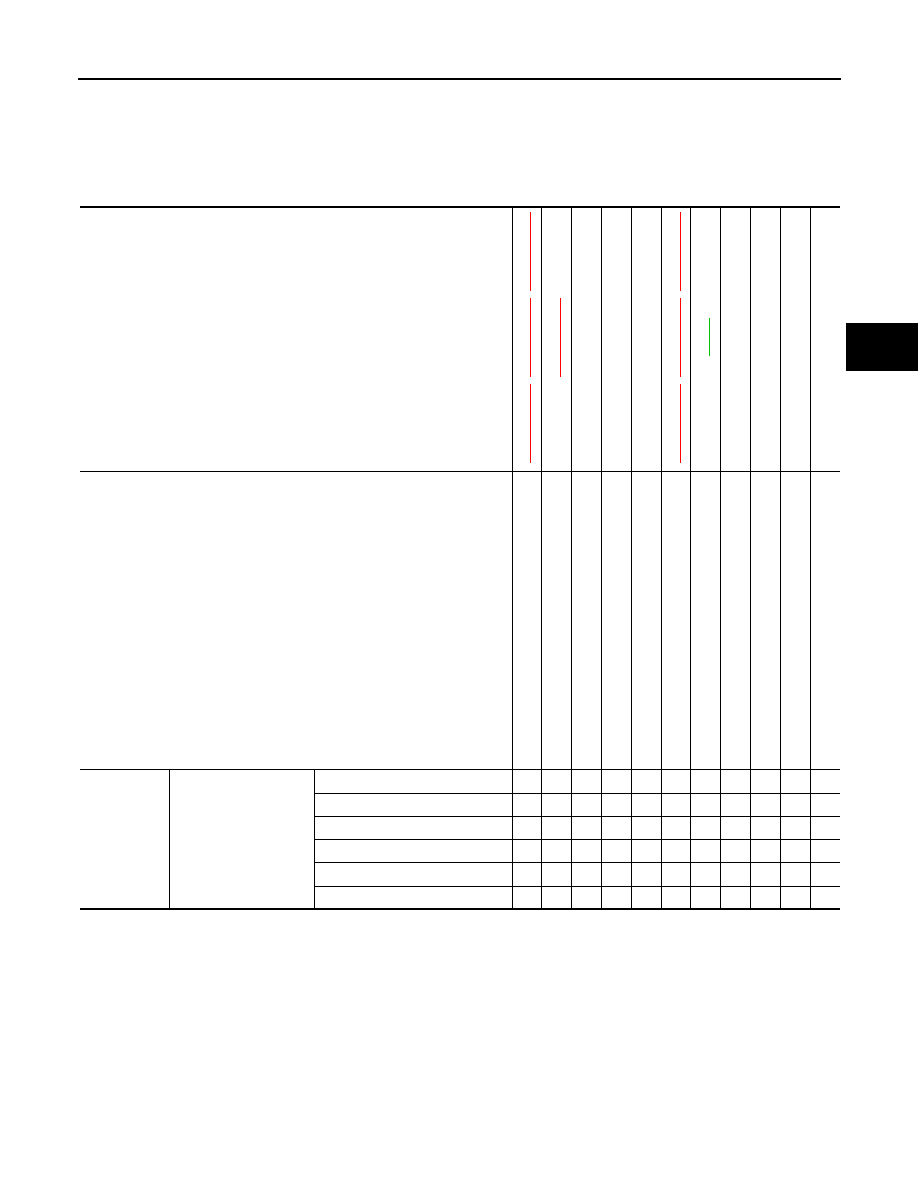

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

INFOID:0000000006044849

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

XX-XX, "****

*"

,

XX-XX

, "*****"

,

XX

-XX, "*****"

XX-XX

, "*****"

—

—

—

XX-XX, "****

*"

,

XX-XX

, "*****"

,

XX

-XX, "*****"

NVH in RAX and RSU sections

NVH in

WT section

NVH in

WT section

NVH in BR

section

Possible cause and SUSPECTED PARTS

Im

prop

er ins

ta

lla

ti

on,

lo

os

en

es

s

Sh

oc

k ab

so

rbe

r de

fo

rma

tio

n,

da

ma

ge

or de

fl

e

c

ti

on

Bu

sh

in

g o

r

m

o

u

n

ti

ng

de

te

ri

ora

ti

o

n

Part

s interference

S

p

ring

fa

tig

u

e

Su

sp

en

si

on

lo

os

en

es

s

Inc

o

rre

c

t whe

e

l al

ig

nm

en

t

REAR AXLE AND REA

R

SUSPENSI

ON

TIRE

ROA

D

WHEEL

BRAKE

Symptom

REAR SUSPENSION

Noise

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

×

Poor quality ride or handling

×

×

×

×

×

×

×

×

×