Nissan March K13. Manual - part 453

MA-18

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

CAUTION:

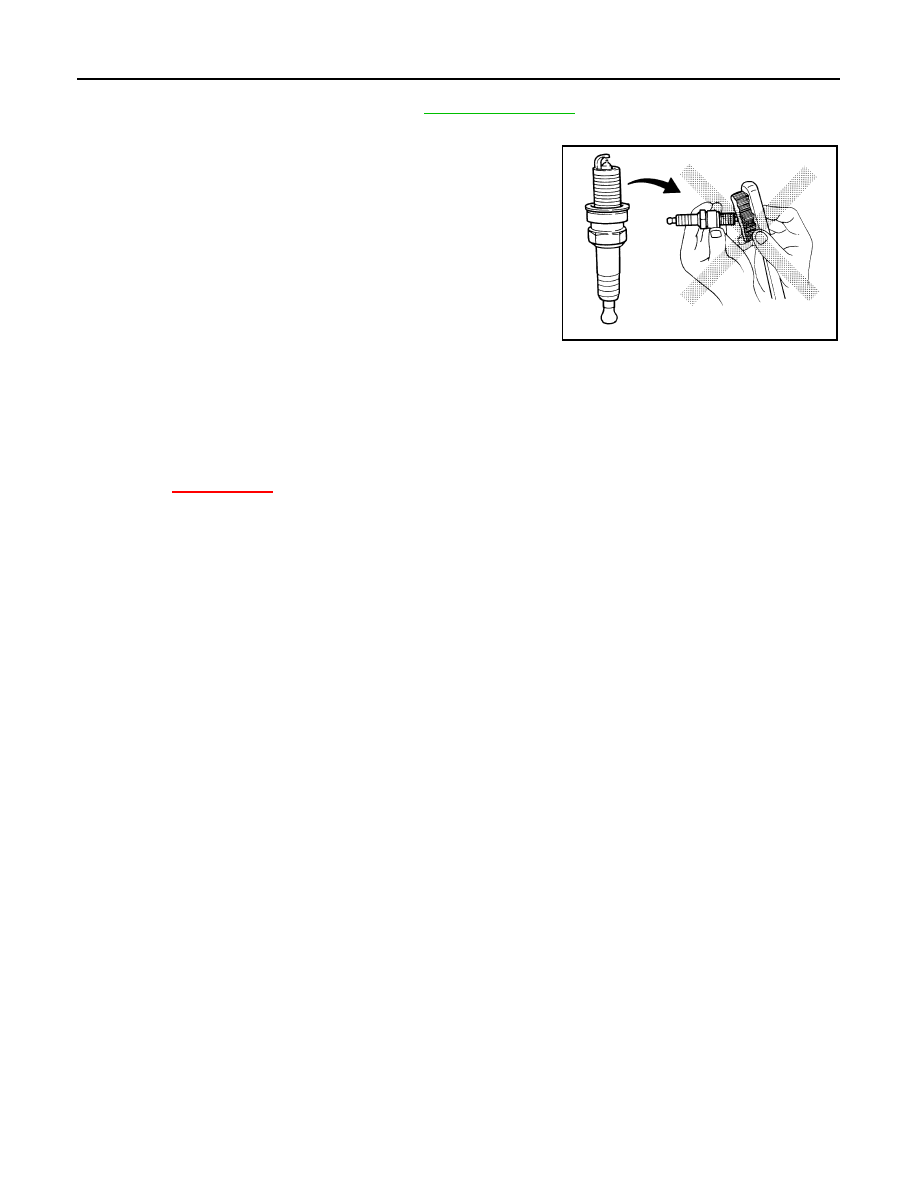

• Never drop or shock spark plug.

• Never use a wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be

used.

EVAP VAPOR LINES

EVAP VAPOR LINES : Inspection

INFOID:0000000005943112

1.

Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2.

Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to

XX-XX, "*****"

.

Spark plug (Standard type)

: Refer to

Cleaner air pressure

: Less than 588 kPa (6 kg/cm

2

,

85 psi)

Cleaning time

: Less than 20 seconds

SMA773C