Nissan March K13. Manual - part 428

IP-22

< REMOVAL AND INSTALLATION >

CENTER CONSOLE ASSEMBLY

4.

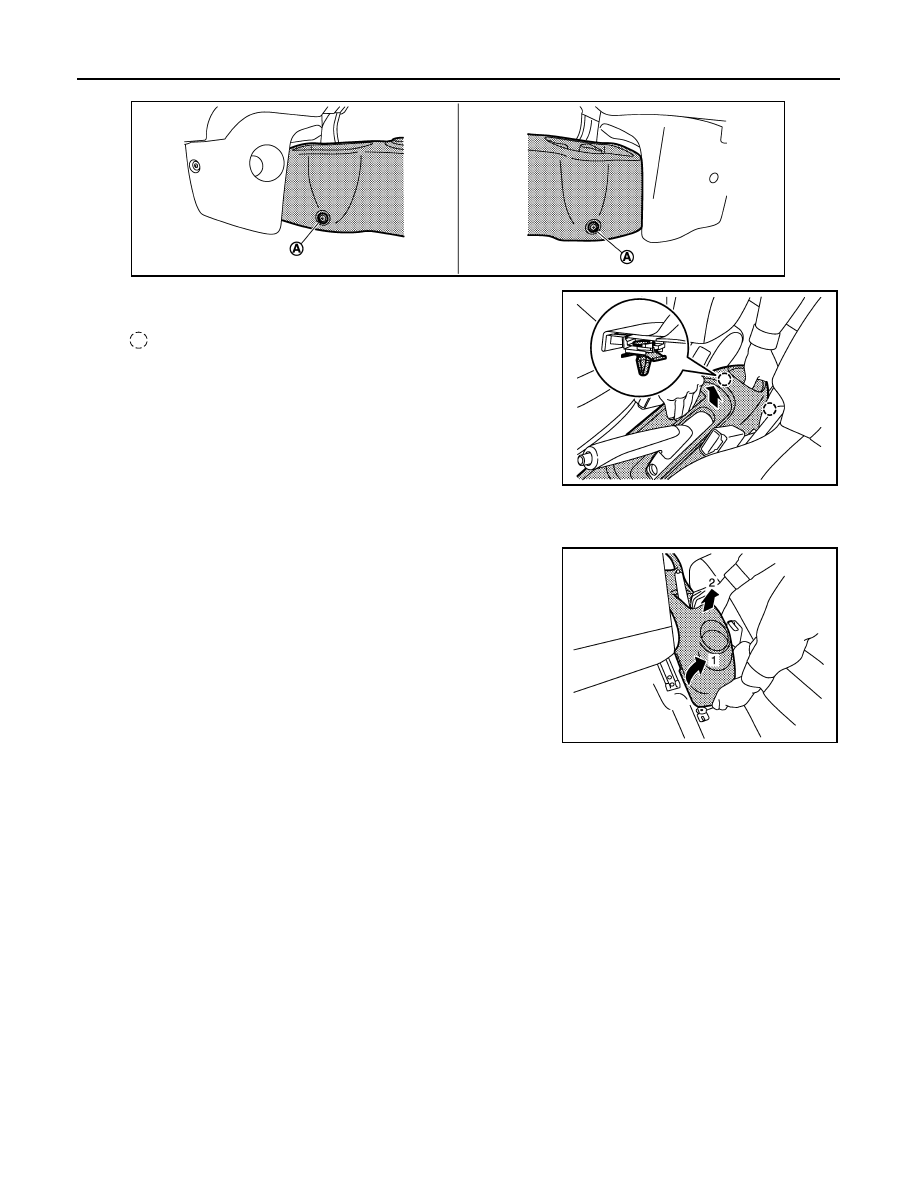

Remove center console assembly fixing clips (A).

5.

Pull up center console assembly to disengage the clips.

6.

Disconnect harness connectors. (with Switches)

7.

Slide front seat RH to the rearmost position and operate to the fully reclining status.

8.

Slide front seat LH to the frontmost position and tilt seatback to the fully forward status.

9.

Lift up rear portion of center console assembly while rotating

and remove center console assembly.

INSTALLATION

Install in the reverse order of removal.

JMJIA3981ZZ

: Clip

JMJIA3982ZZ

JMJIA4077ZZ