Nissan March K13. Manual - part 341

GI-12

< HOW TO USE THIS MANUAL >

HOW TO READ WIRING DIAGRAMS

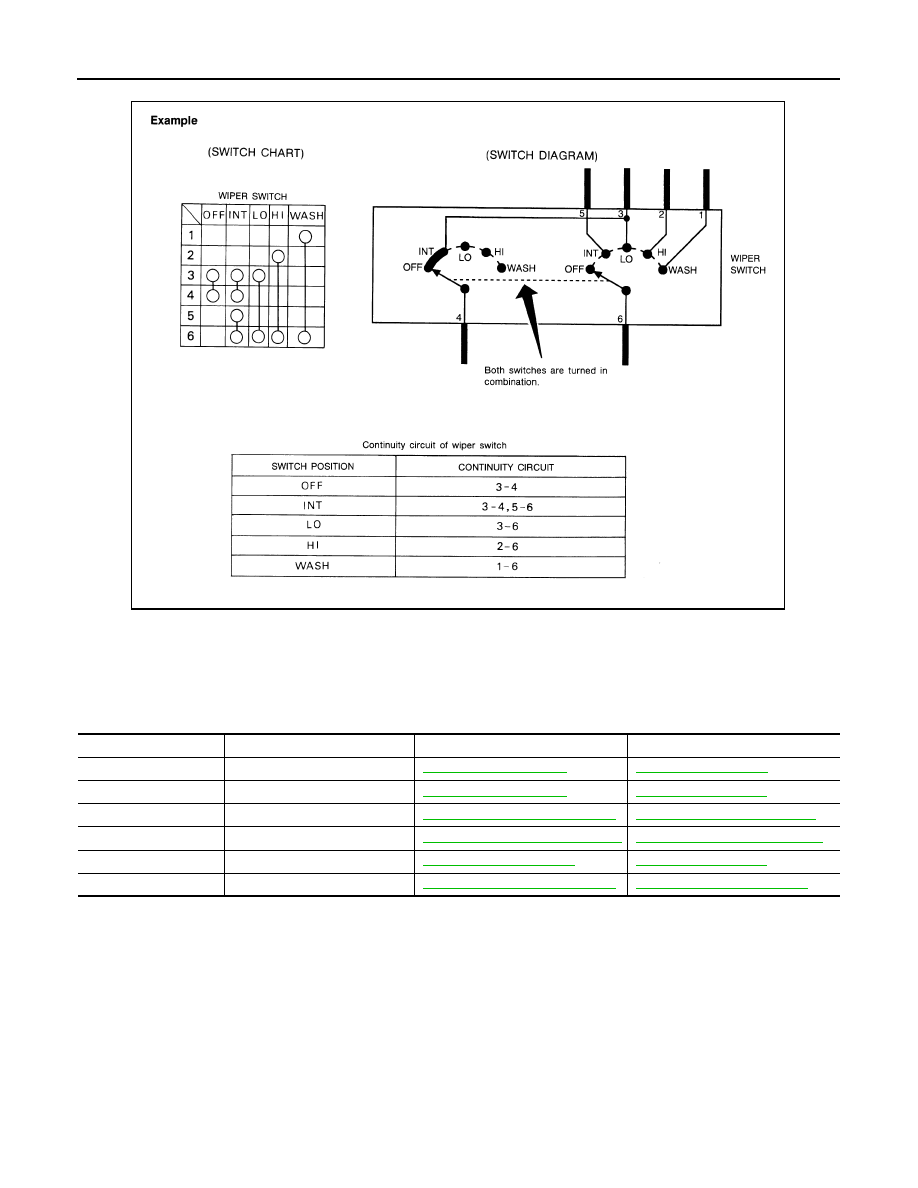

• The switch diagram is used in wiring diagrams.

Connector Information

INFOID:0000000006034280

CONNECTOR LIST

Connector information and harness layout are described in “POWER SUPPLY, GROUND & CIRCUIT ELE-

MENTS” Section.

JSAIA0017GB

Connector No.

Harness

Connector Information

Harness Layout

B

Body harness

D

Door harness

E

Engine room harness

PG-83, "E Engine Room Harness"

F

Engine control harness

PG-96, "F Engine Control Harness"

PG-38, "Engine Control Harness"

M

Main harness

R

Room lamp harness