Nissan March K13. Manual - part 256

FUEL PUMP

EC-485

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

FUEL PUMP

Component Function Check

INFOID:0000000006046395

1.

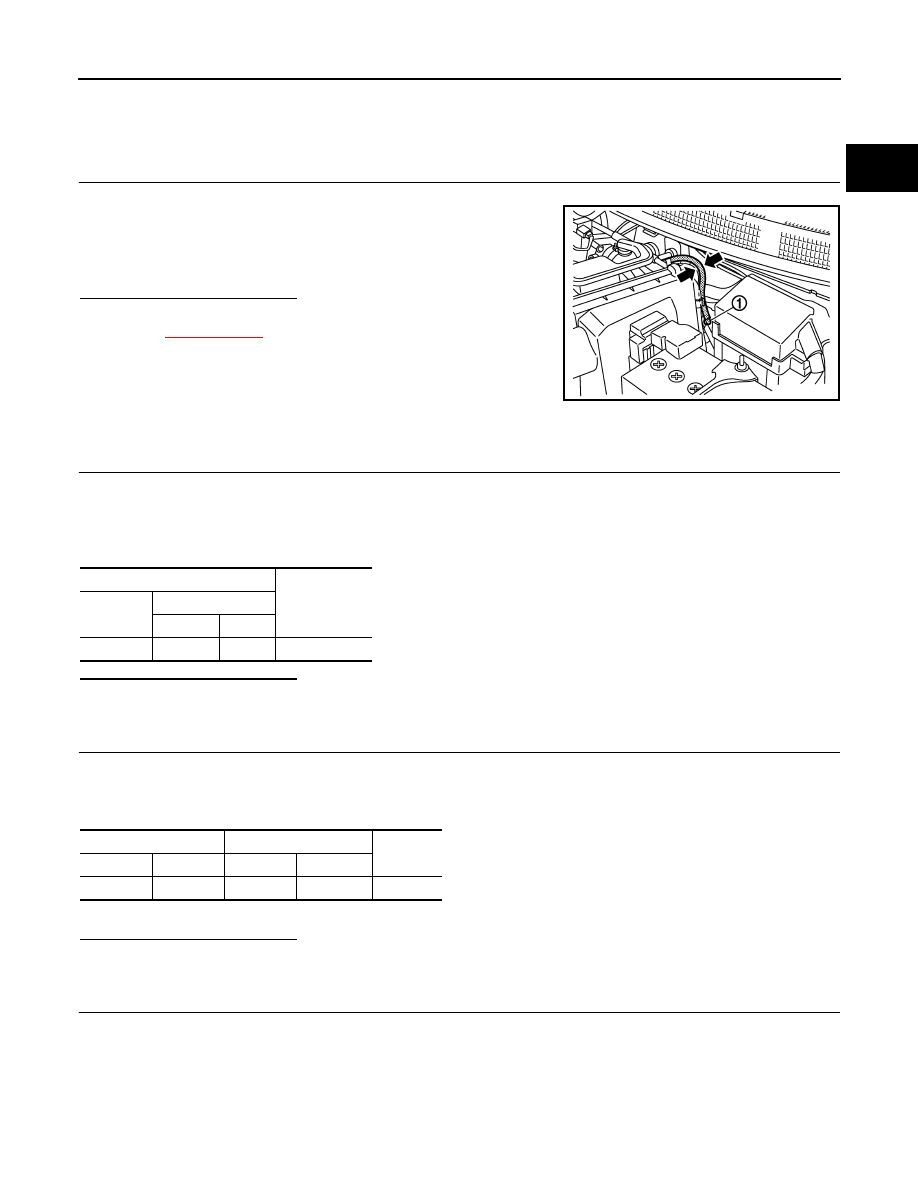

CHECK FUEL PUMP FUNCTION

1.

Turn ignition switch ON.

2.

Pinch fuel feed hose (1) with two fingers.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>>

XX-XX, "*****"

.

Diagnosis Procedure

INFOID:0000000006037615

1.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-I

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 2.

2.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R harness connector.

3.

Check the continuity between IPDM E/R harness connector and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 3.

3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E6, F1

• IPDM E/R connector E12

• Harness for open or short to ground and short power

>> Repair open circuit or short to ground or short to power in harness or connectors.

Fuel pressure pulsation should be felt on the fuel feed

hose for 1 second after ignition switch is turned ON.

JSBIA0377ZZ

ECM

Voltage

Connector

Terminal

+

−

F7

23

108

Battery voltage

ECM

IPDM E/R

Continuity

Connector

Terminal

Connector

Terminal

F7

23

E12

31

Existed