Nissan March K13. Manual - part 254

COOLING FAN

EC-477

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK COOLING FAN MOTOR

EC-477, "Component Inspection"

YES or NO

YES

>> GO TO 5.

NO

>> Replace cooling fan motor.

5.

CHECK INTERMITTENT INCIDENT

Perform

XX-XX, "*****"

.

YES or NO

YES

>> Replace IPDM E/R. Refer to

XX-XX, "*****"

(WITH I-KEY) or

XX-XX, "*****"

(WITHOUT I-KEY).

NO

>> Repair or replace harness or connector.

Component Inspection

INFOID:0000000006037458

1.

CHECK COOLING FAN MOTOR

1.

Turn ignition switch OFF.

2.

Disconnect cooling fan motor harness connector.

3.

Supply cooling fan motor terminals with battery voltage and check operation.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace cooling fan motor.

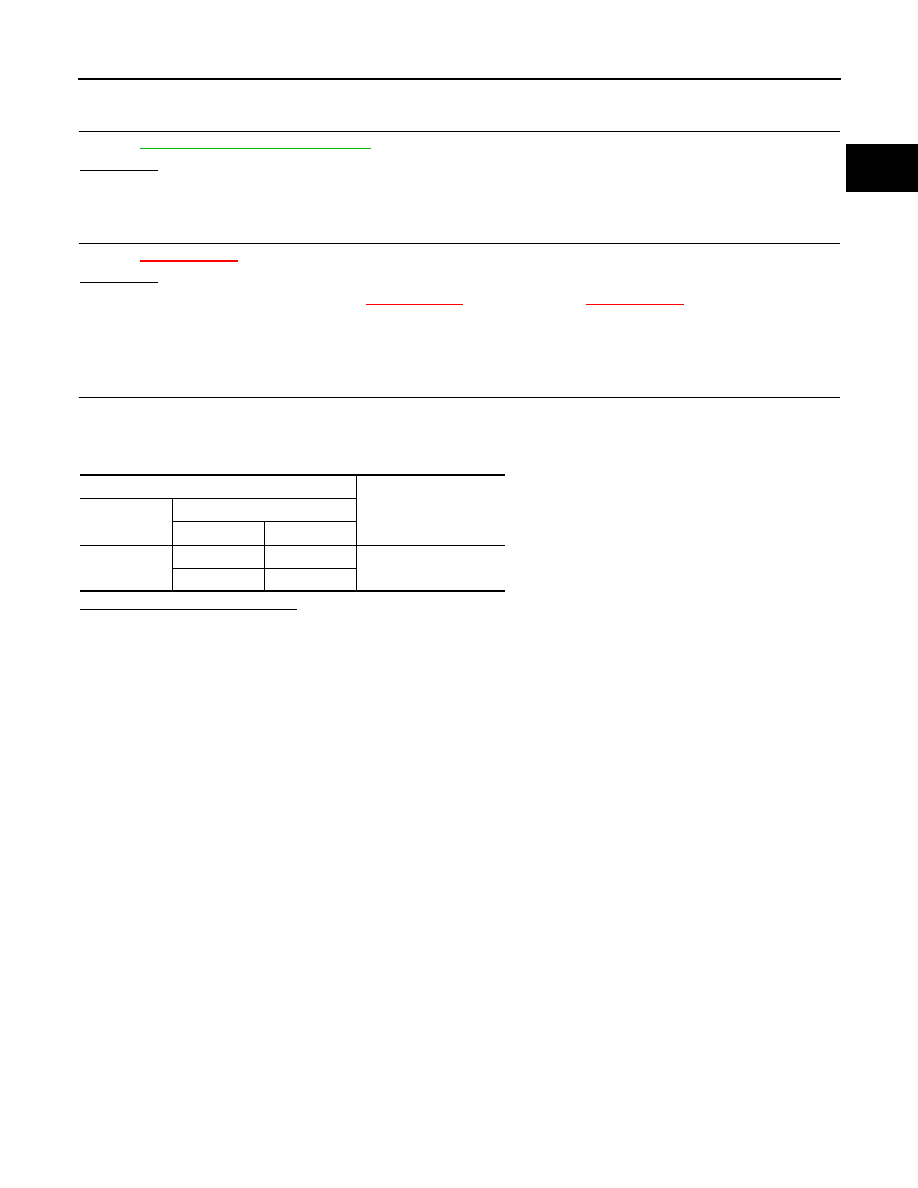

Cooling fan motor

Operation

Connector

terminals

(+)

(

−

)

E62

1

4

Cooling fan operates.

2

3