Nissan March K13. Manual - part 219

SYSTEM

EC-337

< SYSTEM DESCRIPTION >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

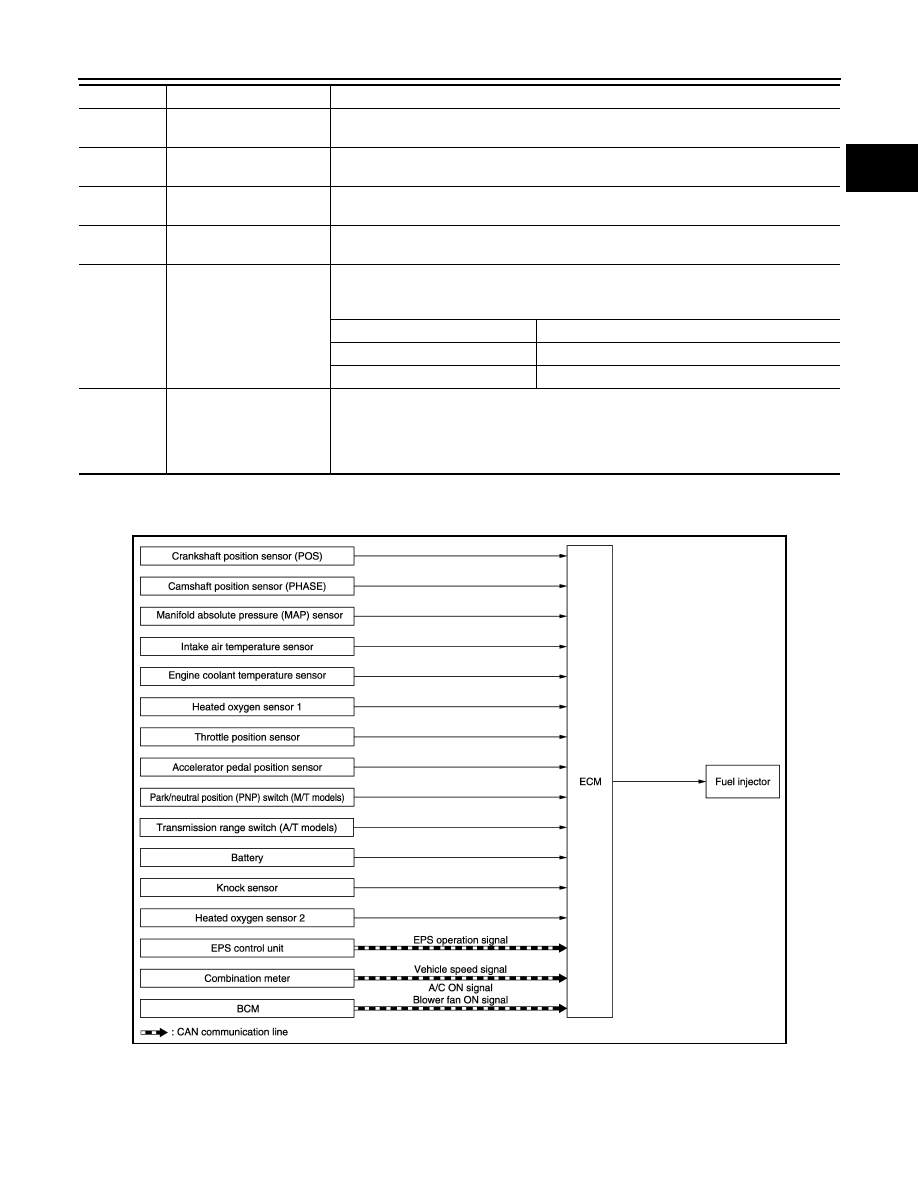

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM : System Diagram

INFOID:0000000006036809

MULTIPORT FUEL INJECTION SYSTEM : System Description

INFOID:0000000006036810

INPUT/OUTPUT SIGNAL CHART

P1124

P1126

Throttle control motor relay

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1128

Throttle control motor

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1171

Intake air

When accelerator pedal is depressed, engine speed will not rise more than 2,500 rpm due

to fuel cut.

P1229

Sensor power supply

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1805

Brake switch

ECM controls the electric throttle control actuator by regulating the throttle opening to a

small range.

Therefore, acceleration will be poor.

Vehicle condition

Driving condition

When engine is idling

Normal

When accelerating

Poor acceleration

P2122

P2123

P2127

P2128

P2138

Accelerator pedal position

sensor

The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

DTC No.

Detected items

Engine operating condition in fail safe mode

JSBIA0434GB