Nissan March K13. Manual - part 144

SYSTEM

EC-37

< SYSTEM DESCRIPTION >

[HR12DE (TYPE 1)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

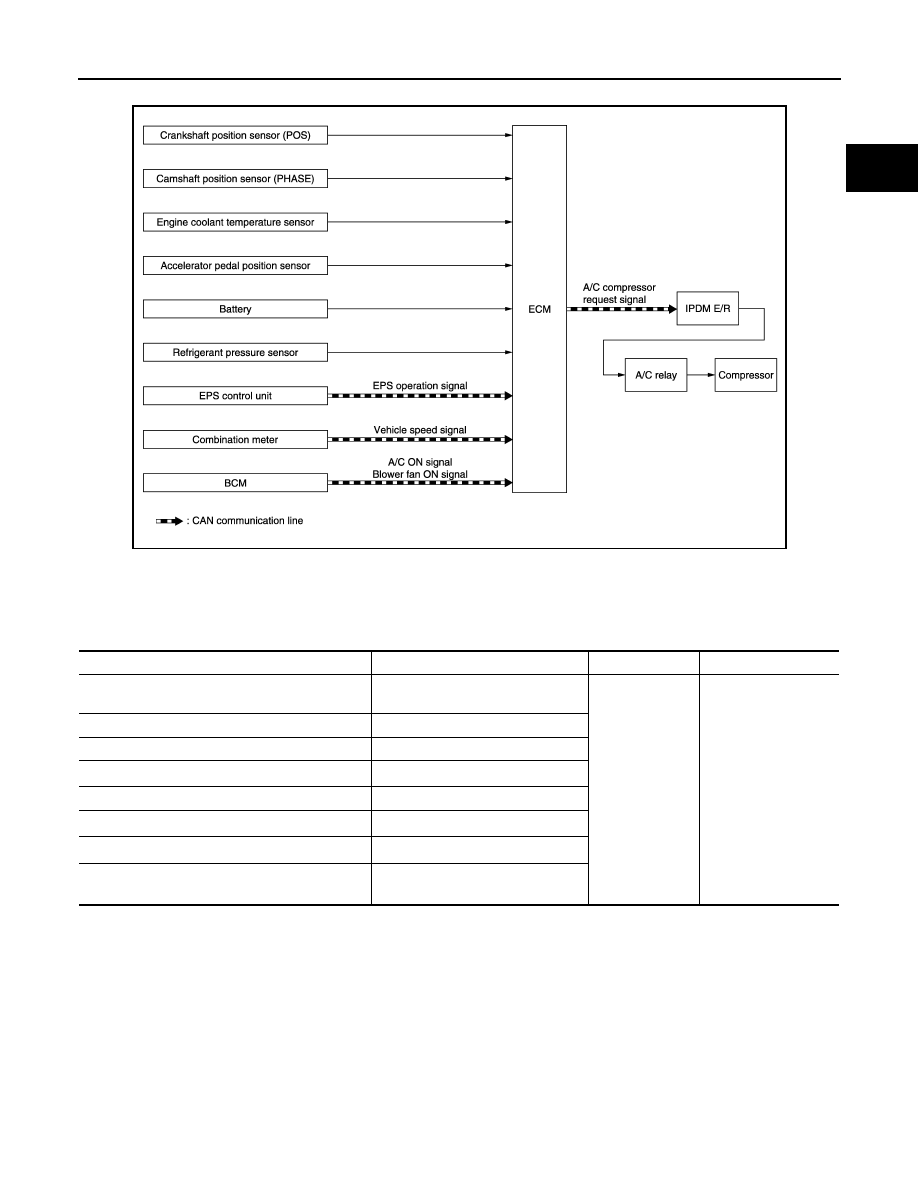

AIR CONDITIONING CUT CONTROL : System Diagram

INFOID:0000000005995404

AIR CONDITIONING CUT CONTROL : System Description

INFOID:0000000005995405

INPUT/OUTPUT SIGNAL CHART

*1: ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

JSBIA0320GB

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)

Engine speed

*1

A/C compressor

repuest signal

IPDM E/R

↓

Air conditioner relay

↓

Compressor

Engine coolant temperature sensor

Engine coolant temperature

Accelerator pedal position sensor

Accelerator pedal position

Battery

Battery voltage

*1

Refrigerant pressure sensor

Refrigerant pressure

EPS control unit

EPS operation signal

*2

Combination meter

Vehicle speed signal

*2

BCM

A/C ON signal

*2

Blower fan ON signal