Nissan March K13. Manual - part 57

CL-12

< REMOVAL AND INSTALLATION >

CLUTCH MASTER CYLINDER

CLUTCH MASTER CYLINDER

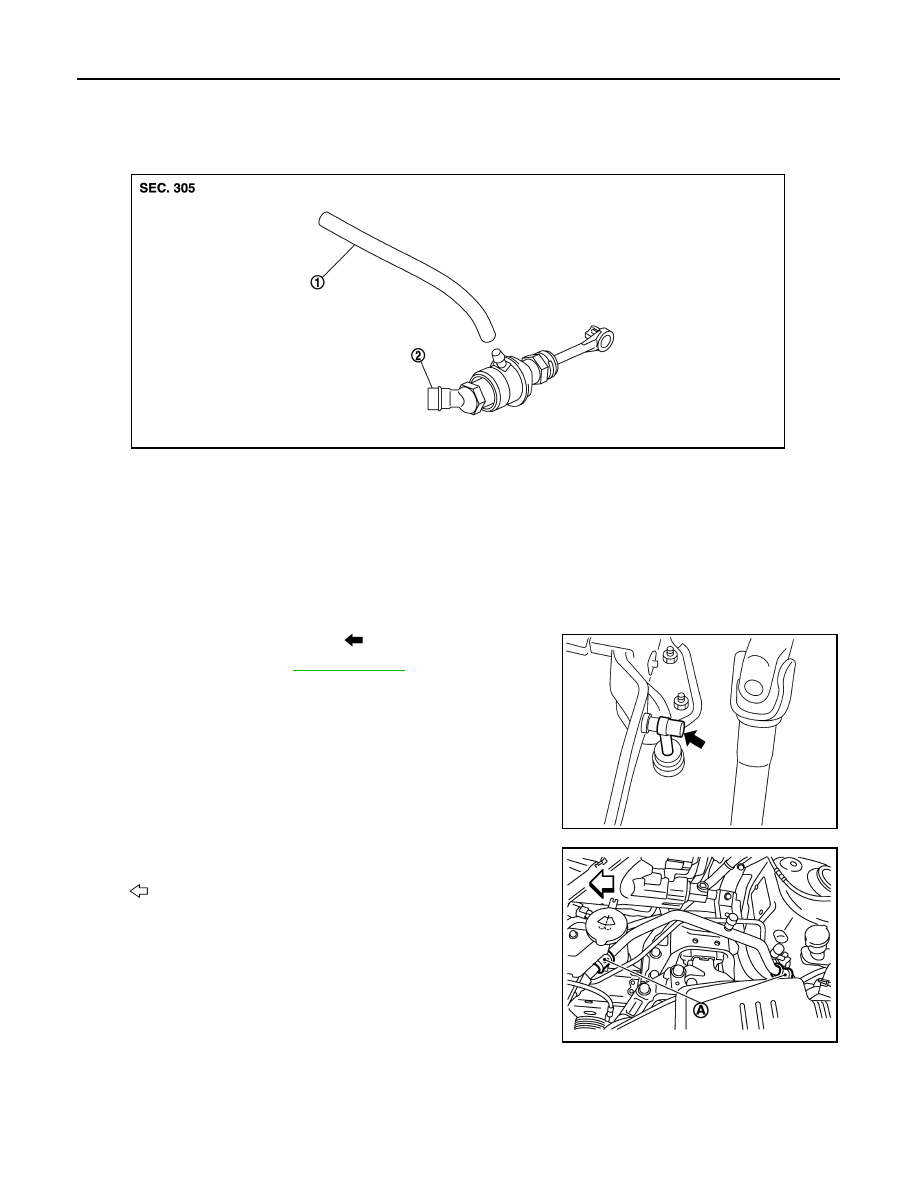

Exploded View

INFOID:0000000006056608

Removal and Installation

INFOID:0000000006056609

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

• Never disassemble clutch master cylinder.

1.

Remove master cylinder rod end (

) from clutch pedal.

2.

Drain clutch fluid. Refer to

.

3.

Remove reservoir hose from reservoir tank and master cylinder.

4.

Remove clips (A) for cooler pipe (low-pressure pipe).

1.

Reservoir hose

2.

Master cylinder

JPDIB0222ZZ

PCIB1491E

: Vehicle front

JPDIB0226ZZ