Nissan GT-R (2007-2014 year). STEERING SYSTEM / TRANSAXLE & TRANSMISSION. Service Manual - part 2

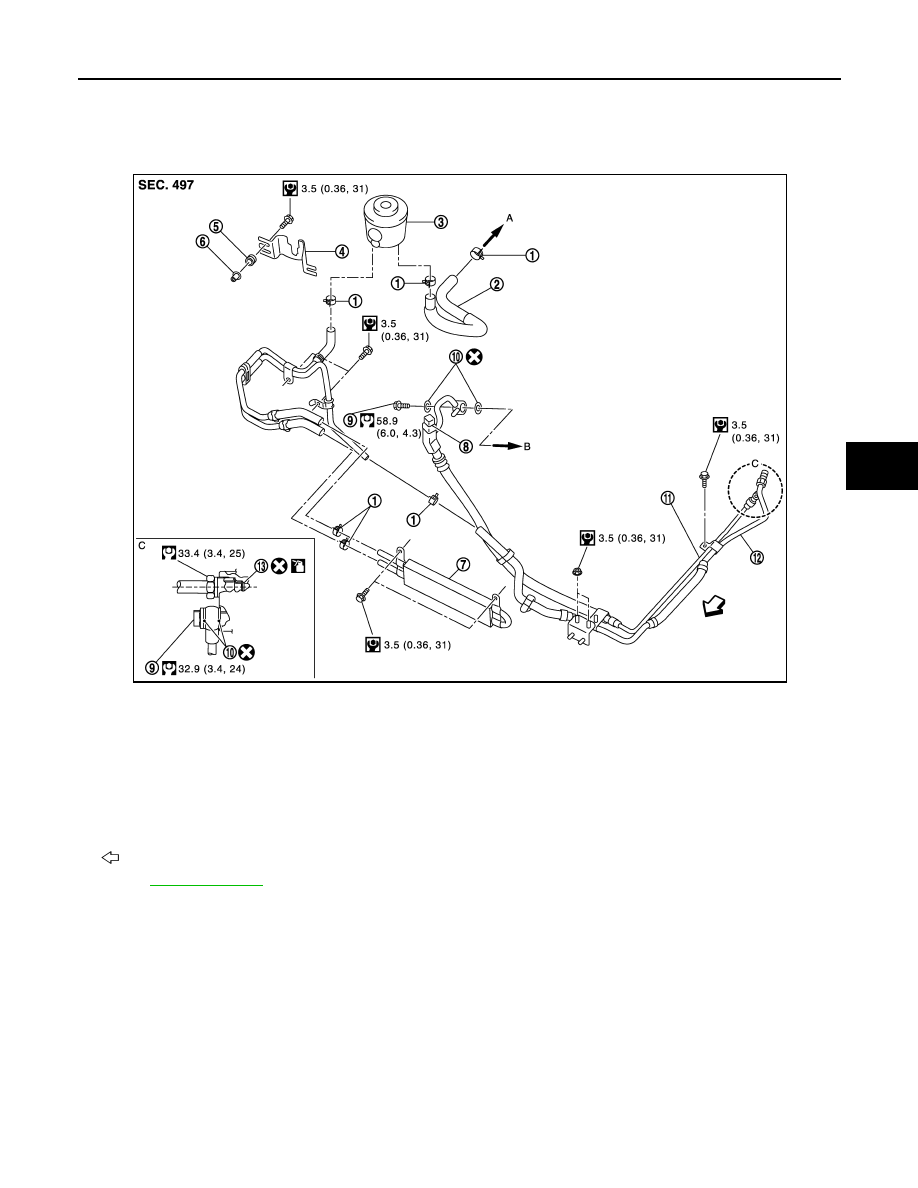

HYDRAULIC LINE

ST-17

< REMOVAL AND INSTALLATION >

C

D

E

F

H

I

J

K

L

M

A

B

ST

N

O

P

HYDRAULIC LINE

Exploded View

INFOID:0000000009160114

1.

Clamp

2.

Suction hose

3.

Reservoir tank

4.

Reservoir tank bracket

5.

Bushing

6.

Collar

7.

Oil cooler

8.

Pressure sensor

9.

Eye bolt

10. Copper washer

11.

High pressure piping

12. Low pressure piping

13. O-ring

A.

To power steering oil pump suction

piping.

B.

To power steering oil pump.

: Vehicle front

Refer to

NNGIA0037GB

2014 GT-R