Nissan GT-R (2007-2014 year). METER, WARNING LAMP & INDICATOR. Service Manual - part 3

MWI

METER SYSTEM

MWI-33

< SYSTEM DESCRIPTION >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

LOW BRAKE FLUID WARNING

Control Outline

• The combination meter receives the brake fluid level switch signal from the brake fluid level switch.

• Based on the received brake fluid level switch signal, the combination meter displays the low brake fluid

warning.

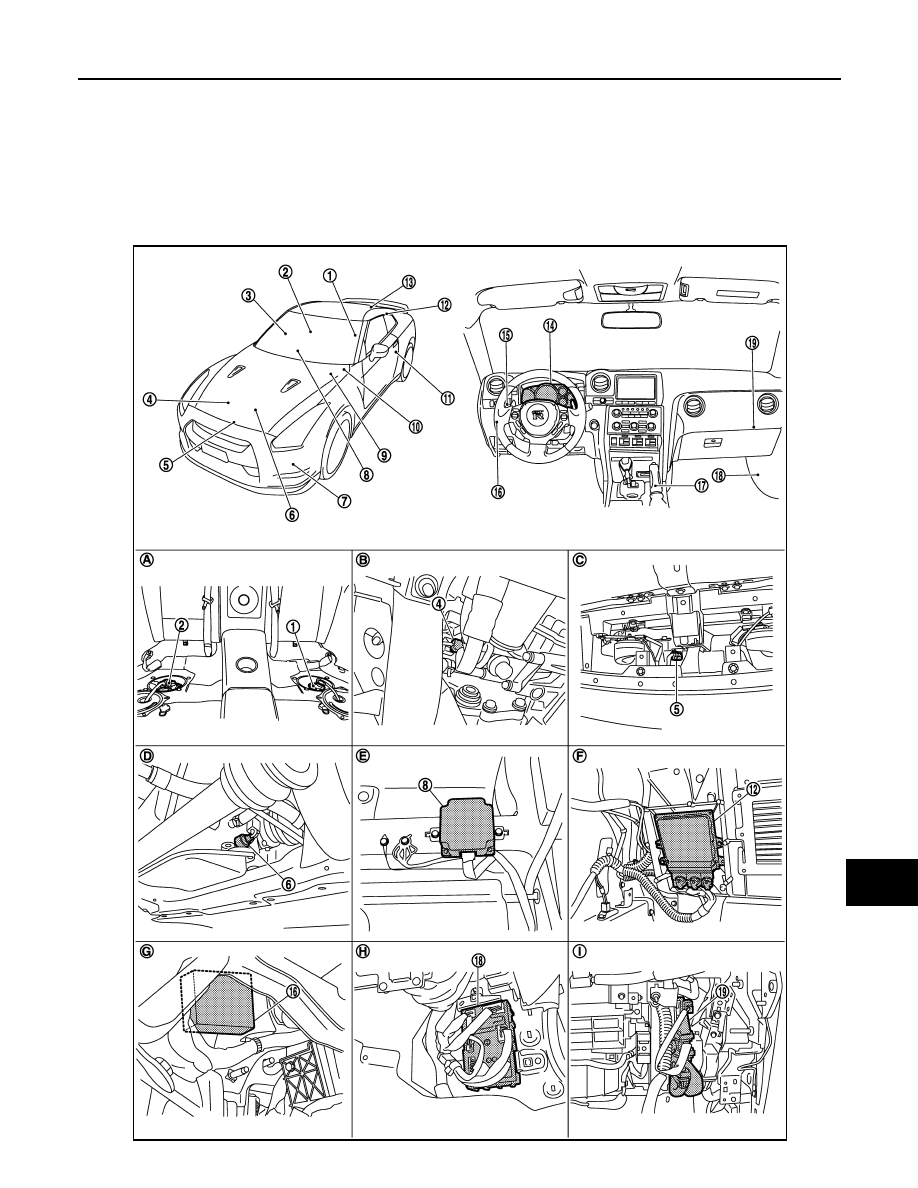

INFORMATION DISPLAY : Component Parts Location

INFOID:0000000009189328

JPNIA1142ZZ

Revision: 2012 November

2014 GT-R