Nissan GT-R (2007-2014 year). INSTRUMENT PANEL / LAN SYSTEM / MAINTENANCE. Service Manual - part 2

INSTRUMENT PANEL ASSEMBLY

IP-17

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

K

L

M

A

B

IP

N

O

P

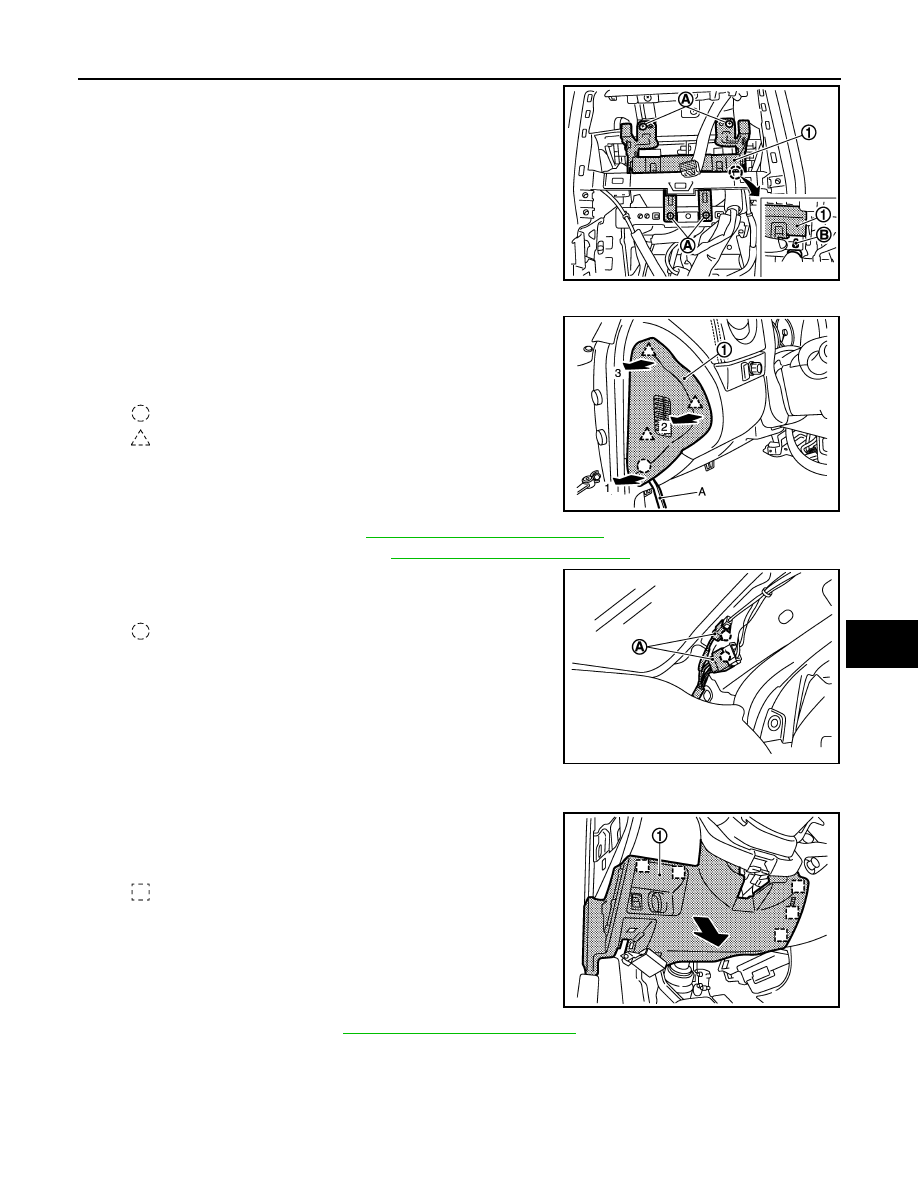

1.

Remove fixing screws (A) of A/C auto amp (1).

2.

Disengage joint of harness clamp (B).

3.

Pull back A/C auto amp.

4.

Disconnect harness connectors on the back.

14. Remove instrument side finisher LH.

1.

Insert remover tool (A) between instrument side finisher LH

(1) and instrument panel assembly.

2.

Pull instrument side finisher LH in lateral direction of vehicle

in order from 1 - 3, and then disengage clip and pawls.

15. Remove body side welt LH. Refer to

INT-15, "Removal and Installation"

.

16. Remove front pillar garnish LH. Refer to

INT-15, "Removal and Installation"

17. Disconnect harness connectors (A) from front pillar LH and

remove clips.

18. Remove instrument lower panel (driver).

1.

Remove hood opener lever mounting bolts.

2.

Pull back instrument lower panel (driver) (1) toward vehicle

lower, and then disengage metal clips.

3.

Disconnect harness connectors on the back.

19. Remove steering wheel. Refer to

ST-10, "Removal and Installation"

.

20. Remove steering column front lower cover.

NNJIA0063ZZ

: Clip

: Pawl

JMJIA2184ZZ

: Clip

JMJIA2185ZZ

: Metal clip

JMJIA2186ZZ

Revision: 2012 November

2014 GT-R