Nissan GT-R (2007-2014 year). EXHAUST SYSTEM / EXTERIOR LIGHTING SYSTEM. Service Manual - part 2

EXL-14

< SYSTEM DESCRIPTION >

[XENON TYPE]

BACK-UP LAMP SYSTEM

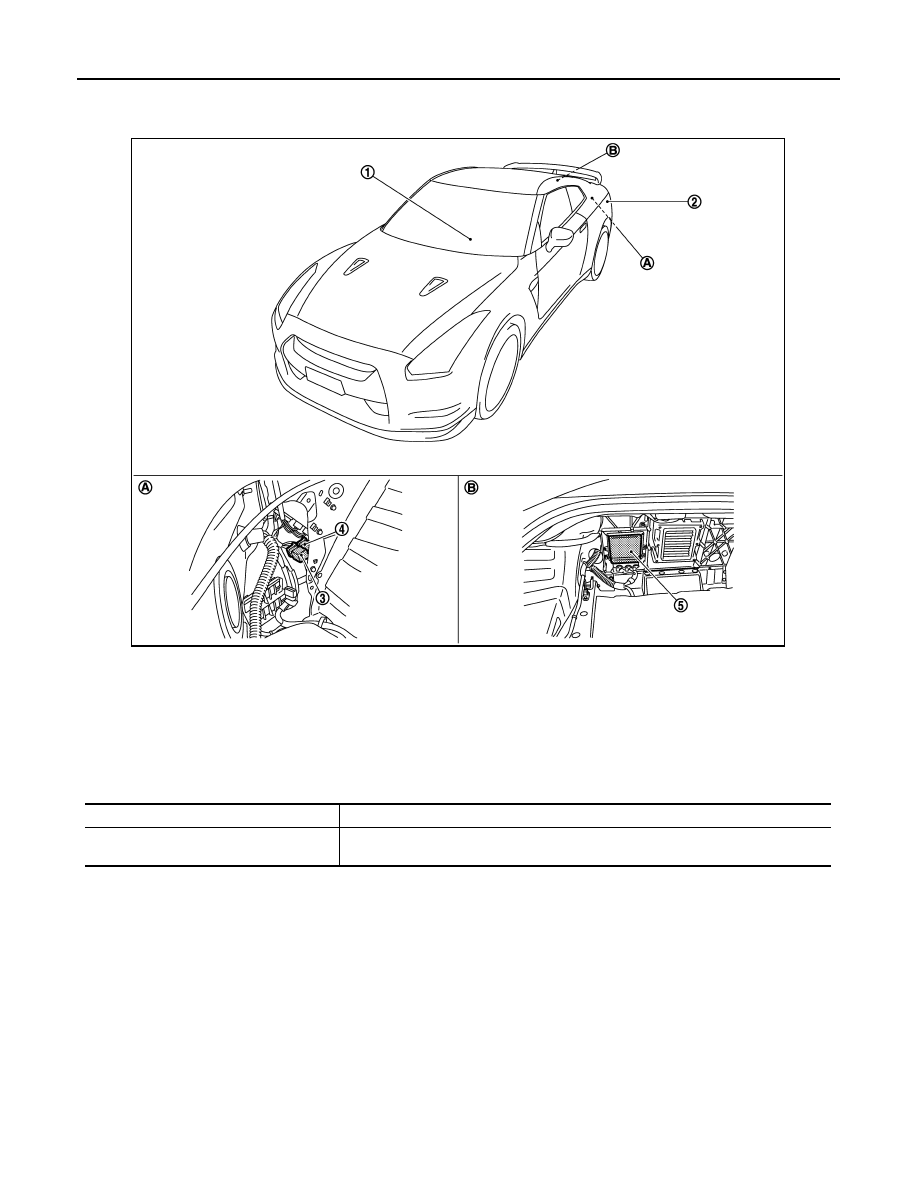

Component Parts Location

INFOID:0000000009160305

Component Description

INFOID:0000000009160306

1.

Control device

2.

Back-up lamp

3.

TCM relay

4.

Back-up lamp relay

5.

TCM

A.

Inside of rear wheel house finisher

(LH)

B.

Inside of trunk front finisher

NNLIA0021ZZ

Part

Description

TCM

• Detects the control device condition.

• Judges the back-up lamp relay ON/OFF by shift lever position status.

Revision: 2012 November

2014 GT-R