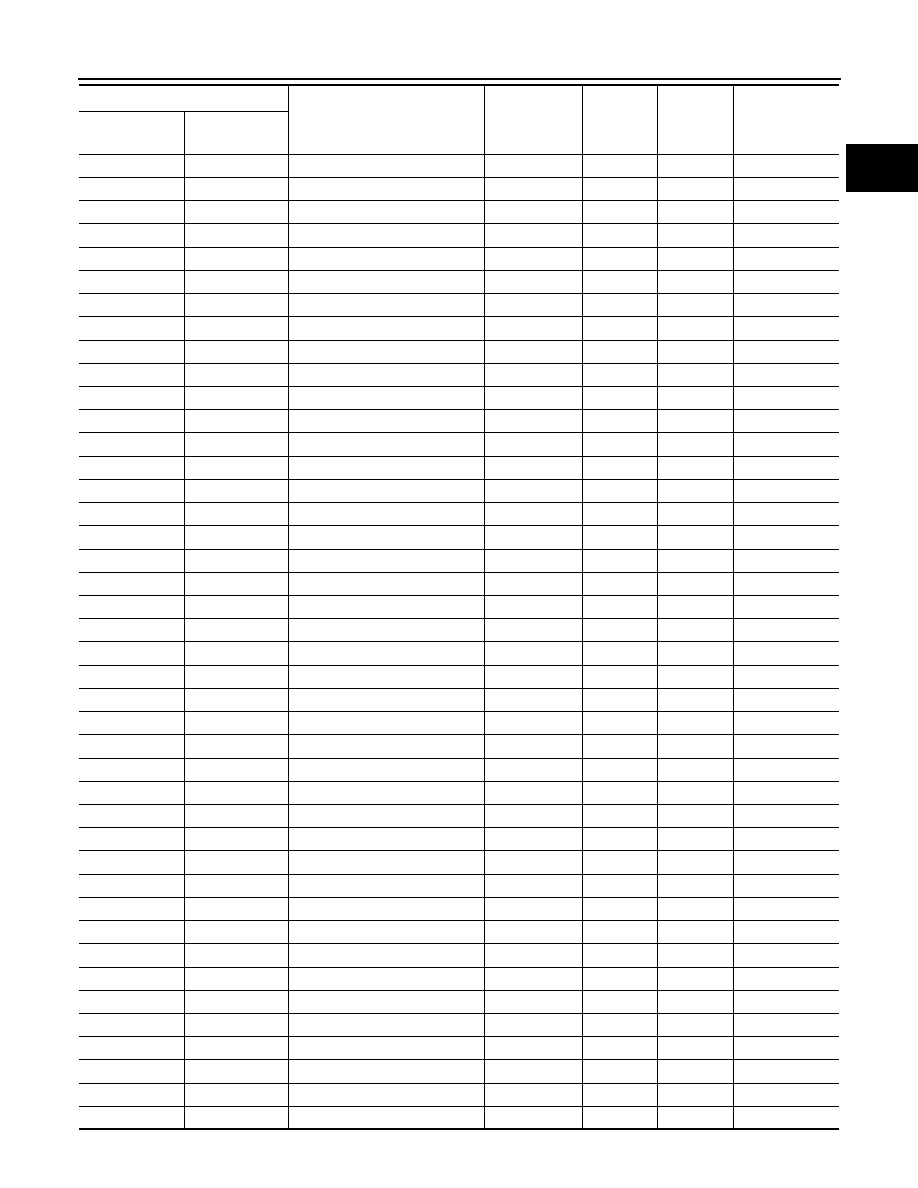

Nissan GT-R (2007-2014 year). ENGINE CONTROL SYSTEM / ENGINE MECHANICAL. Service Manual - part 2

ECM

EC-17

< ECU DIAGNOSIS INFORMATION >

[VR38]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0850

0850

P-N POS SW/CIRCUIT

—

2

×

B

P1148

1148

CLOSED LOOP-B1

—

1

×

A

P1168

1168

CLOSED LOOP-B2

—

1

×

A

P1211

1211

TCS C/U FUNCTN

—

2

—

—

P1212

1212

TCS/CIRC

—

2

—

—

P1217

1217

ENG OVER TEMP

—

1

×

B

P1220

1220

FPCM

—

1

—

—

P1225

1225

CTP LEARNING-B1

—

2

—

—

P1226

1226

CTP LEARNING-B1

—

2

—

—

P1233

1233

ETC FNCTN/CIRC-B2

—

1

×

B

P1234

1234

CTP LEARNING-B2

—

2

—

—

P1235

1235

CTP LEARNING-B2

—

2

—

—

P1236

1236

ETC MOT-B2

—

1

×

B

P1238

1238

ETC ACTR-B2

—

1

×

B

P1239

1239

TP SENSOR-B2

—

1

×

B

P1263

1263

TC SYSTEM-B2

—

2

—

—

P1290

1290

ETC MOT PWR-B2

—

1

×

B

P1334

1334

TC SYSTEM-B2

—

1

×

B

P1421

1421

COLD START CONTROL

—

2

×

A

P1550

1550

BAT CURRENT SENSOR

—

2

—

—

P1551

1551

BAT CURRENT SENSOR

—

2

—

—

P1552

1552

BAT CURRENT SENSOR

—

2

—

—

P1553

1553

BAT CURRENT SENSOR

—

2

—

—

P1554

1554

BAT CURRENT SENSOR

—

2

—

—

P1564

1564

ASCD SW

—

1

—

—

P1572

1572

ASCD BRAKE SW

—

1

—

—

P1574

1574

ASCD VHL SPD SEN

—

1

—

—

P1610

1610

LOCK MODE

—

2

—

—

P1611

1611

ID DISCORD,IMMU-ECM

—

2

—

—

P1612

1612

CHAIN OF ECM-IMMU

—

2

—

—

P1614

1614

CHAIN OF IMMU-KEY

—

2

—

—

P1615

1615

DIFFERENCE OF KEY

—

2

—

—

P1805

1805

BRAKE SW/CIRCUIT

—

2

—

—

P2096

2096

POST CAT FUEL TRIM SYS B1

—

2

×

A

P2097

2097

POST CAT FUEL TRIM SYS B1

—

2

×

A

P2098

2098

POST CAT FUEL TRIM SYS B2

—

2

×

A

P2099

2099

POST CAT FUEL TRIM SYS B2

—

2

×

A

P2100

2100

ETC MOT PWR-B1

—

1

×

B

P2101

2101

ETC FNCTN/CIRC-B1

—

1

×

B

P2103

2103

ETC MOT PWR

—

1

×

B

P2118

2118

ETC MOT-B1

—

1

×

B

P2119

2119

ETC ACTR-B1

—

1

×

B

DTC*

1

Items

(CONSULT screen terms)

SRT code

Trip

MIL

Permanent DTC

group*

4

CONSULT

GST*

2

ECM*

3

Revision: 2012 November

2014 GT-R