содержание .. 130 131 132 133 ..

Nissan GT-R. Manual - part 132

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-17

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

- Always adjust to toe-in. If the wheels change to toe-out, tire partial wear is accelerated and local heating may

be accelerated in the inner side of tires.

- Always adjust toe-in to 1.5 mm (0.059 in) or less because too much toe-in may promote local heat genera-

tion.

- For the above reasons, always adjust to toe-in for the vehicle of a customer who drives on a racetrack.

- Engaging in performance driving on a racetrack and ultra-high-speed driving, be sure to adjust toe-in to 1.5

mm (0.059 in) or less. If used beyond this range, it is not covered by the warranty.

• Insufficient negative camber during hard cornering on a racetrack may result in tire wear. Therefore, recom-

mend the customer to adjust negative camber angle in the negative direction when driving on a racetrack.

[To avoid uneven wear, recommend the customer to have the camber angle aligned in the positive direction

at an inspection after performance driving (at customer's expense).]

• Wheel alignment can be changed in process of time and mileage, as suspension parts do not adjust to each

other up to the mileage of about 1,000 miles or 2,000 km.

• Remarks for up to the mileage of 1,000 miles or 2,000 km

- Toe angle of one-side wheel: See reference value.

• Each part of the suspension may not conform during a normal driving because of the adoption of a hard rate

coil spring and a high damping shock absorber.

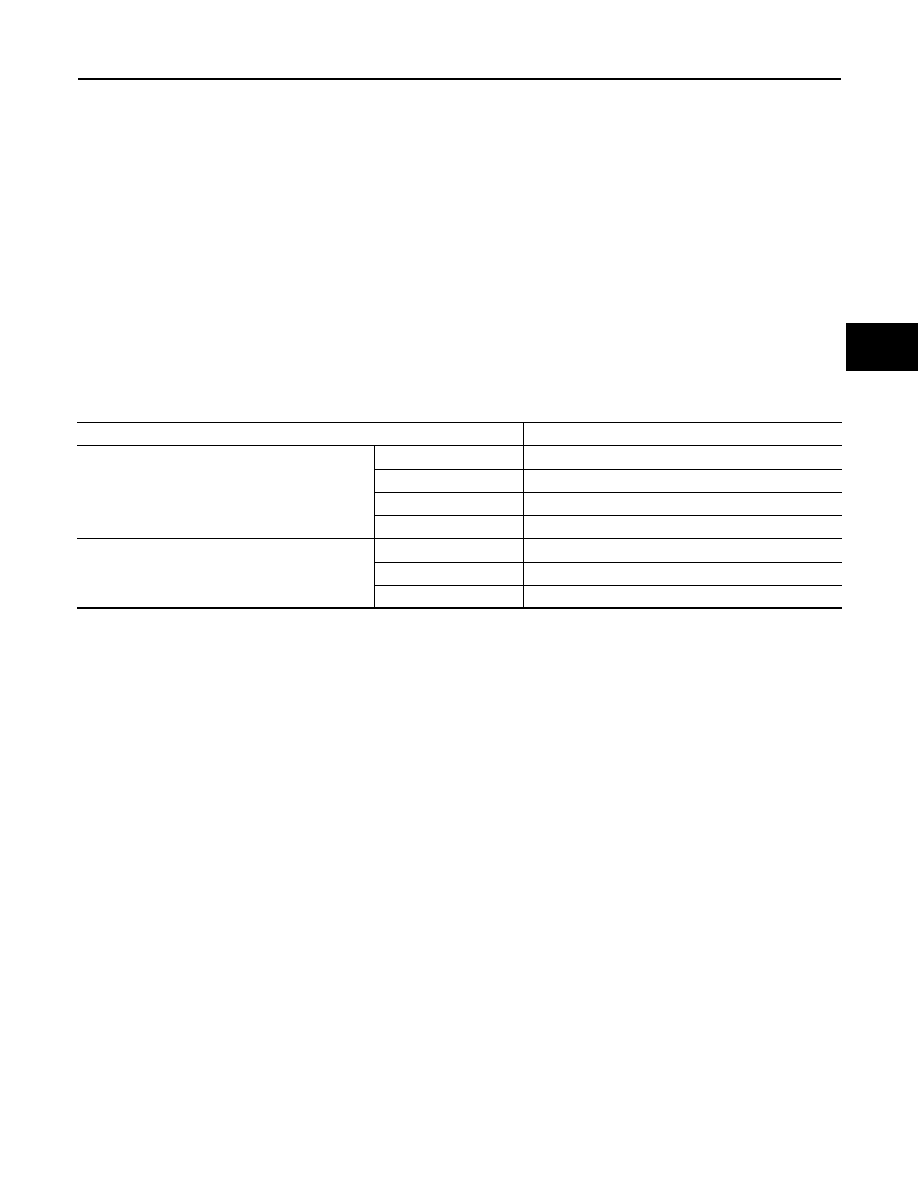

CASTER, KINGPIN INCLINATION

Measure value under unladen

*

conditions.

*: Fuel, engine coolant and lubricant are full. Jack, hand tools and mats are in designated positions.

• Wheel alignment can be changed in process of time and mileage, as suspension parts do not adjust to each

other up to the mileage of about 1,000 miles or 2,000 km.

• Each part of the suspension may not conform during a normal driving because of the adoption of a hard rate

coil spring and a high damping shock absorber.

Item

Standard

Caster

Degree minute (Decimal degree)

Minimum

5

°

45

′

(5.75

°

)

Nominal

6

°

05

′

(6.08

°

)

Maximum

6

°

45

′

(6.75

°

)

Left and right difference

0

°

30

′

(0.50

°

) or less

Kingpin inclination

Degree minute (Decimal degree)

Minimum

9

°

30

′

(9.50

°

)

Nominal

9

°

40

′

(9.67

°

)

Maximum

9

°

50

′

(9.83

°

)