содержание .. 84 85 86 87 ..

Nissan GT-R. Manual - part 86

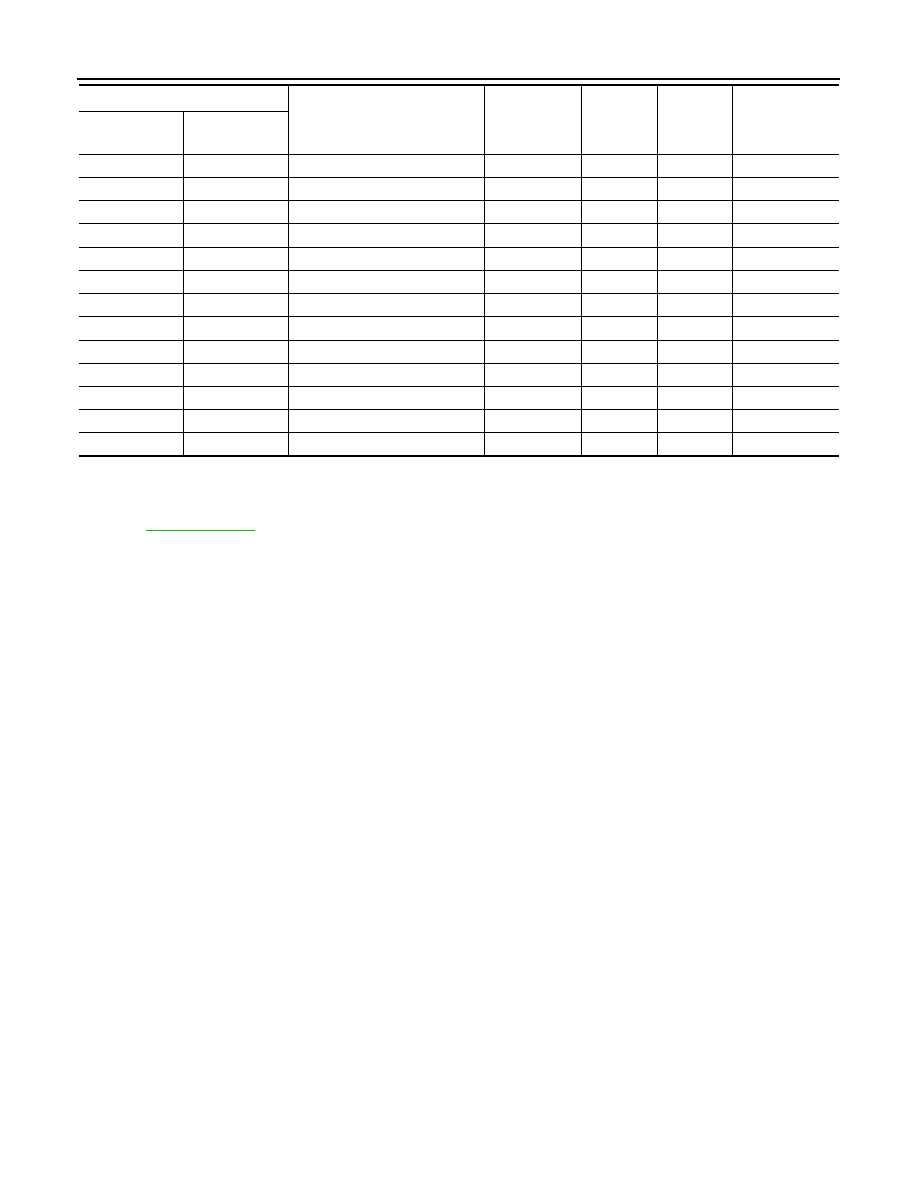

EC-18

< ECU DIAGNOSIS INFORMATION >

[VR38]

ECM

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012/ISO 15031-6.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: Refer to

, “HOW TO ERASE PERMANENT DTC”.

*5: The troubleshooting for this DTC needs CONSULT.

*6: When the ECM is in the mode that displays SRT status, MIL may blink. For the details, refer to “How to Display SRT Status”.

*7: SRT code will not be set if the self-diagnostic result is NG.

*8: When the fail-safe operations for both self-diagnoses occur, the MIL illuminates.

P2122

2122

APP SEN 1/CIRC

—

1

×

B

P2123

2123

APP SEN 1/CIRC

—

1

×

B

P2127

2127

APP SEN 2/CIRC

—

1

×

B

P2128

2128

APP SEN 2/CIRC

—

1

×

B

P2132

2132

TP SEN 1/CIRC-B2

—

1

×

B

P2133

2133

TP SEN 1/CIRC-B2

—

1

×

B

P2135

2135

TP SENSOR-B1

—

1

×

B

P2138

2138

APP SENSOR

—

1

×

B

P2263

2263

TC SYSTEM-B1

—

2

—

—

P2432

2432

SNDRY MAS A/F SE

—

2

×

B

P2433

2433

SNDRY MAS A/F SE

—

2

×

B

P2440

2440

AIR CUT S/V-B1

×

1 or 2

×

B

P2442

2442

AIR CUT S/V-B2

×

2

×

B

DTC*

1

Items

(CONSULT screen terms)

SRT code

Trip

MIL

Permanent DTC

group*

4

CONSULT

GST*

2

ECM*

3