Nissan Pathfinder (2012 year). Manual - part 591

PREPARATION

TM-155

< PREPARATION >

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

PREPARATION

PREPARATION

Special Service Tool

INFOID:0000000007357289

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

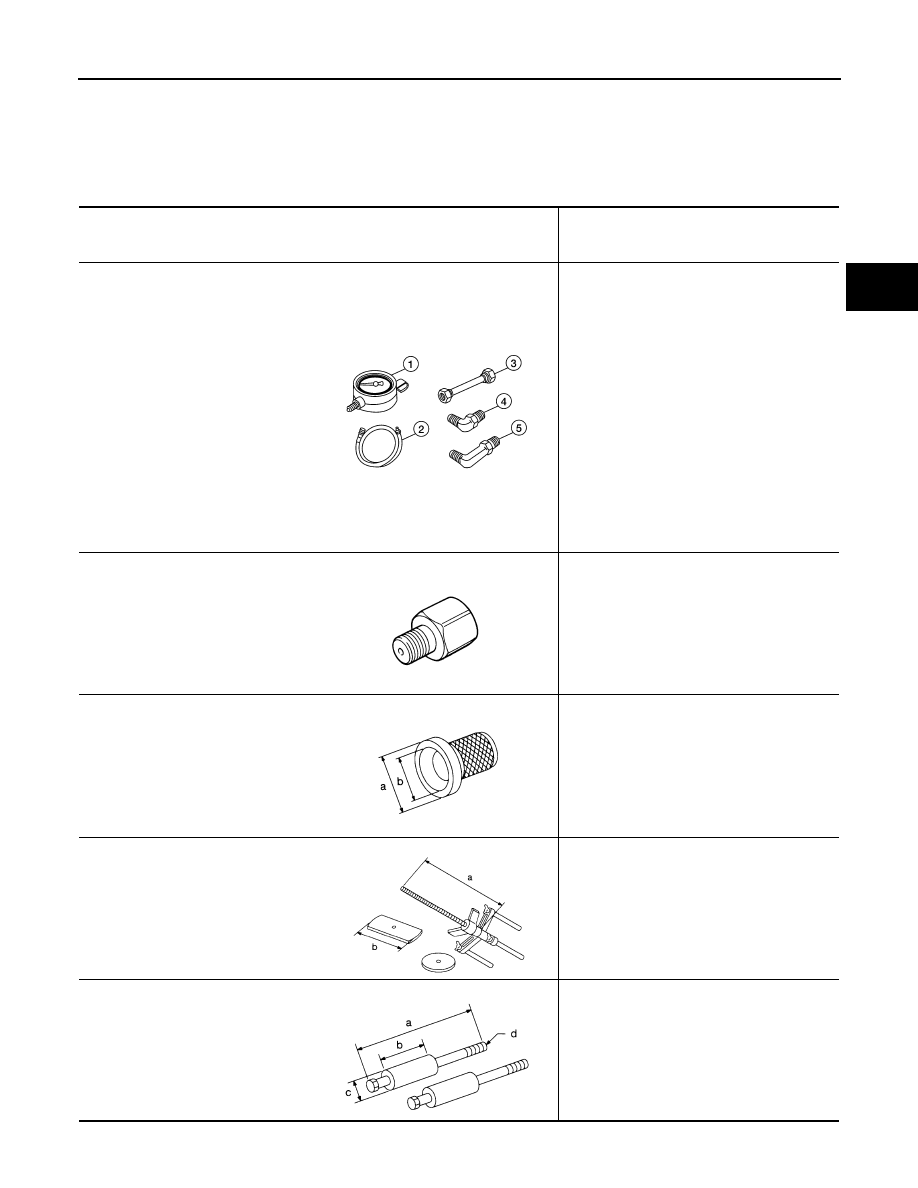

ST2505S001

(J-34301-C)

Oil pressure gauge set

1 ST25051001

( — )

Oil pressure gauge

2 ST25052000

( — )

Hose

3 ST25053000

( — )

Joint pipe

4 ST25054000

( — )

Adapter

5 ST25055000

( — )

Adapter

Measuring line pressure

KV31103600

(J-45674)

Joint pipe adapter

(With ST25054000)

Measuring line pressure

ST33400001

(J-26082)

Drift

• Installing rear oil seal (2WD models)

• Installing oil pump housing oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

KV31102400

(J-34285 and J-34285-87)

Clutch spring compressor

Installing reverse brake return spring retainer

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

ST25850000

(J-25721-A)

Sliding hammer

Remove oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in)

d: M12X1.75P

LCIA0399E

ZZA1227D

NT086

NT423

NT422

August 2012

2012 Pathfinder