Nissan Pathfinder (2012 year). Manual - part 590

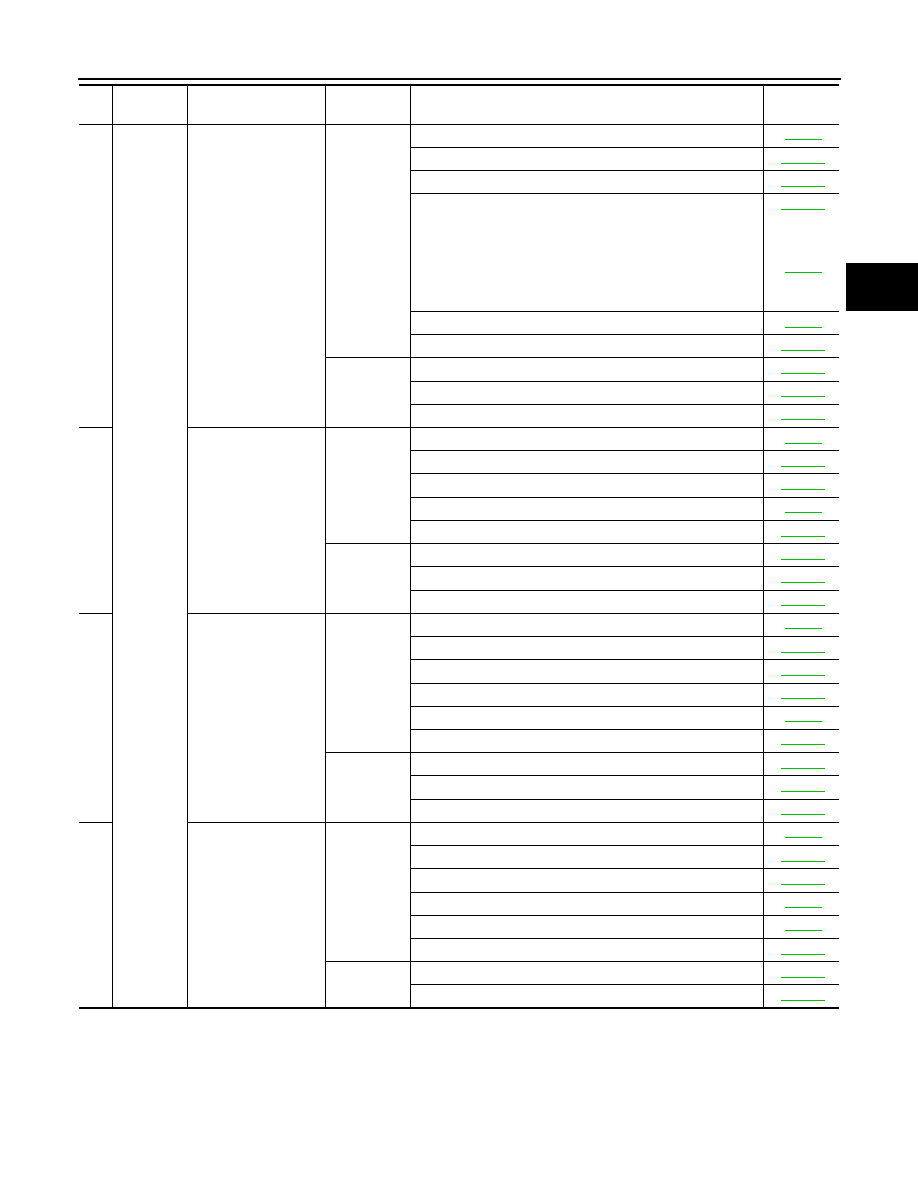

SYSTEM SYMPTOM

TM-147

< SYMPTOM DIAGNOSIS >

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

58

Others

Vehicle does not de-

celerate by engine

brake.

ON vehicle

1. Transmission range switch

2. Fluid level and state

3. Control cable adjustment

4. 1st position switch (without manual mode), manual mode

switch (with manual mode)

(without

manual

mode),

(with man-

ual mode)

5. CAN communication line

6. Control valve with TCM

OFF vehicle

7. Input clutch

8. High and low reverse clutch

9. Direct clutch

59

Engine brake does not

operate in “2” position.

ON vehicle

1. Transmission range switch

2. Fluid level and state

3. Control cable adjustment

7. CAN communication line

8. Control valve with TCM

OFF vehicle

9. Front brake (brake band)

10. Input clutch

11. High and low reverse clutch

60

Engine brake does not

operate in “1” position.

ON vehicle

1. Transmission range switch

2. Fluid level and state

3. Control cable adjustment

4. 1st position switch

5. CAN communication line

6. Control valve with TCM

OFF vehicle

7. Input clutch

8. High and low reverse clutch

9. Direct clutch

61

Engine brake does not

work M

5

→

M4.

ON vehicle

1. Transmission range switch

2. Fluid level and state

3. Control cable adjustment

4. Manual mode switch

5. CAN communication line

6. Control valve with TCM

OFF vehicle

7. Front brake (brake band)

8. Input clutch

No.

Items

Symptom

Condition

Diagnostic Item

Reference

page

August 2012

2012 Pathfinder