Nissan Pathfinder (2012 year). Manual - part 390

FSU-10

< PERIODIC MAINTENANCE >

ON-VEHICLE SERVICE

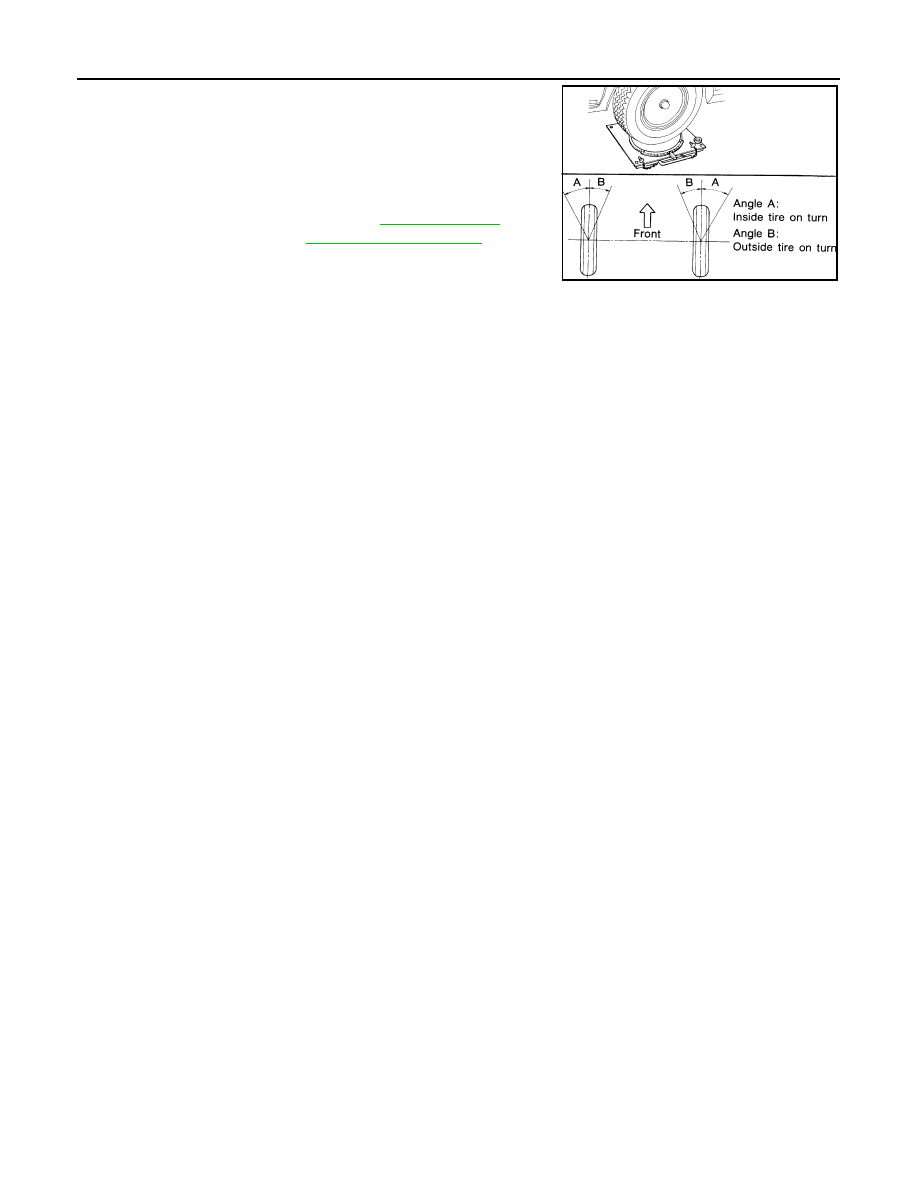

1. Place front wheels on turning radius gauges in straight ahead

position and rear wheels on stands so that vehicle can be level.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

2. Start engine and run at idle, turn steering wheel all the way right

and left, measure the turning angle.

• Any turning angles are not adjustable. If any of steering angles

are out of the specification, check if the following parts are

worn or damaged.

- Steering gear

- Steering column

- Front suspension components

If found that they are worn or damaged, replace them with new ones.

Wheel turning angle

(full turn)

: Refer to

.

SFA439BA

August 2012

2012 Pathfinder