Nissan Pathfinder (2012 year). Manual - part 356

FUEL PUMP

EC-929

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

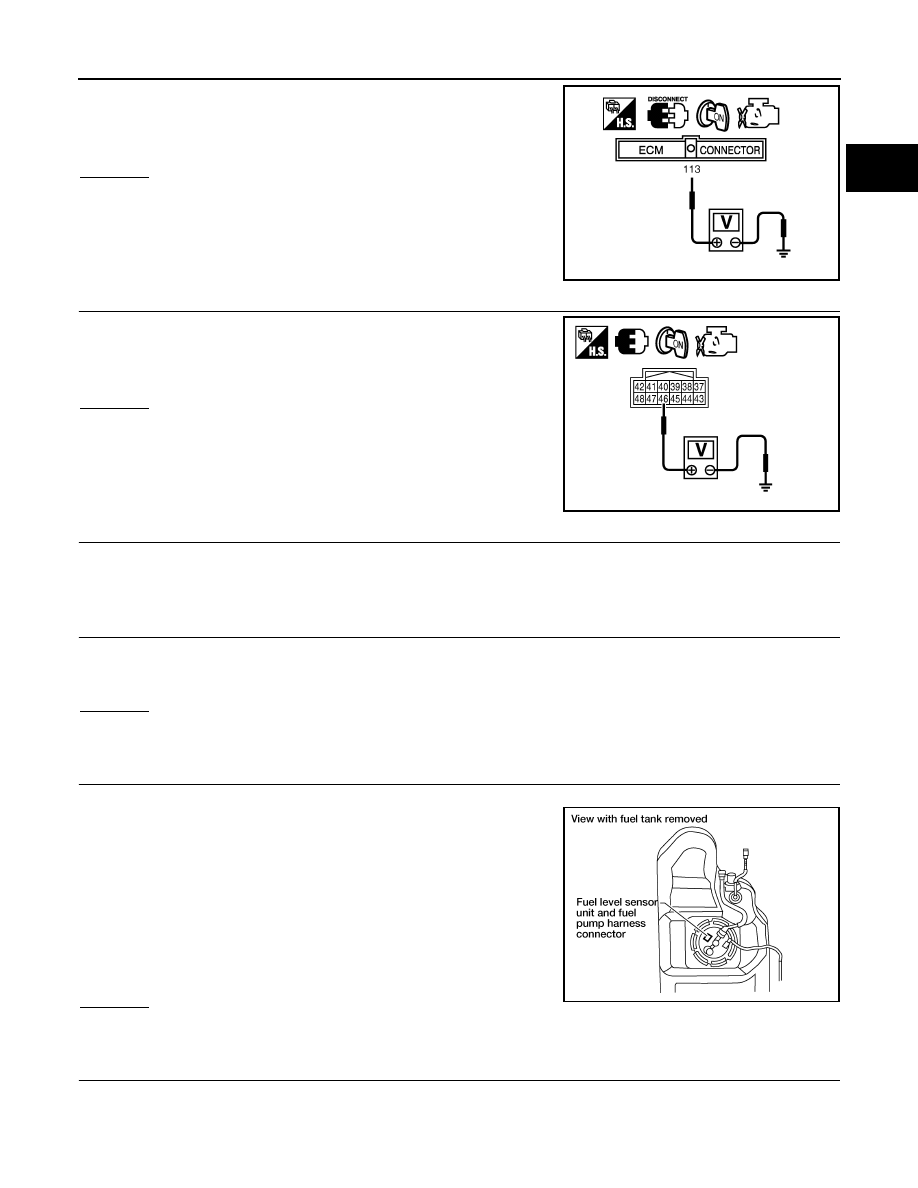

4. Check voltage between ECM terminal 113 and ground with

CONSULT or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 3.

3.

CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

Check voltage between IPDM E/R terminal 46 and ground with

CONSULT or tester.

OK or NG

OK

>> GO TO 4.

NG

>> GO TO 9.

4.

DETECT MALFUNCTIONING PART

Check harness for open or short between IPDM E/R and ECM.

>> Repair harness or connectors.

5.

CHECK FUSE

1. Turn ignition switch OFF.

2. Disconnect 15 A fuse (No. 48).

3. Check 15 A fuse.

OK or NG

OK

>> GO TO 6.

NG

>> Replace fuse.

6.

CHECK FUEL PUMP POWER SUPPLY AND GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness con-

nector.

3. Disconnect IPDM E/R harness connector E119.

4. Check harness continuity between IPDM E/R terminal 13 and

“fuel level sensor unit and fuel pump” terminal 1, “fuel level sen-

sor unit and fuel pump” terminal 3 and ground.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E41, C1

• Harness for open or short between fuel pump and IPDM E/R

Voltage: Battery voltage

PBIB1187E

Voltage: Battery voltage

PBIB2656E

Continuity should exist.

BBIA0545E

August 2012

2012 Pathfinder