Nissan Pathfinder (2012 year). Manual - part 265

P0181 FTT SENSOR

EC-201

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

>>

INSPECTION END

Component Inspection

INFOID:0000000007358112

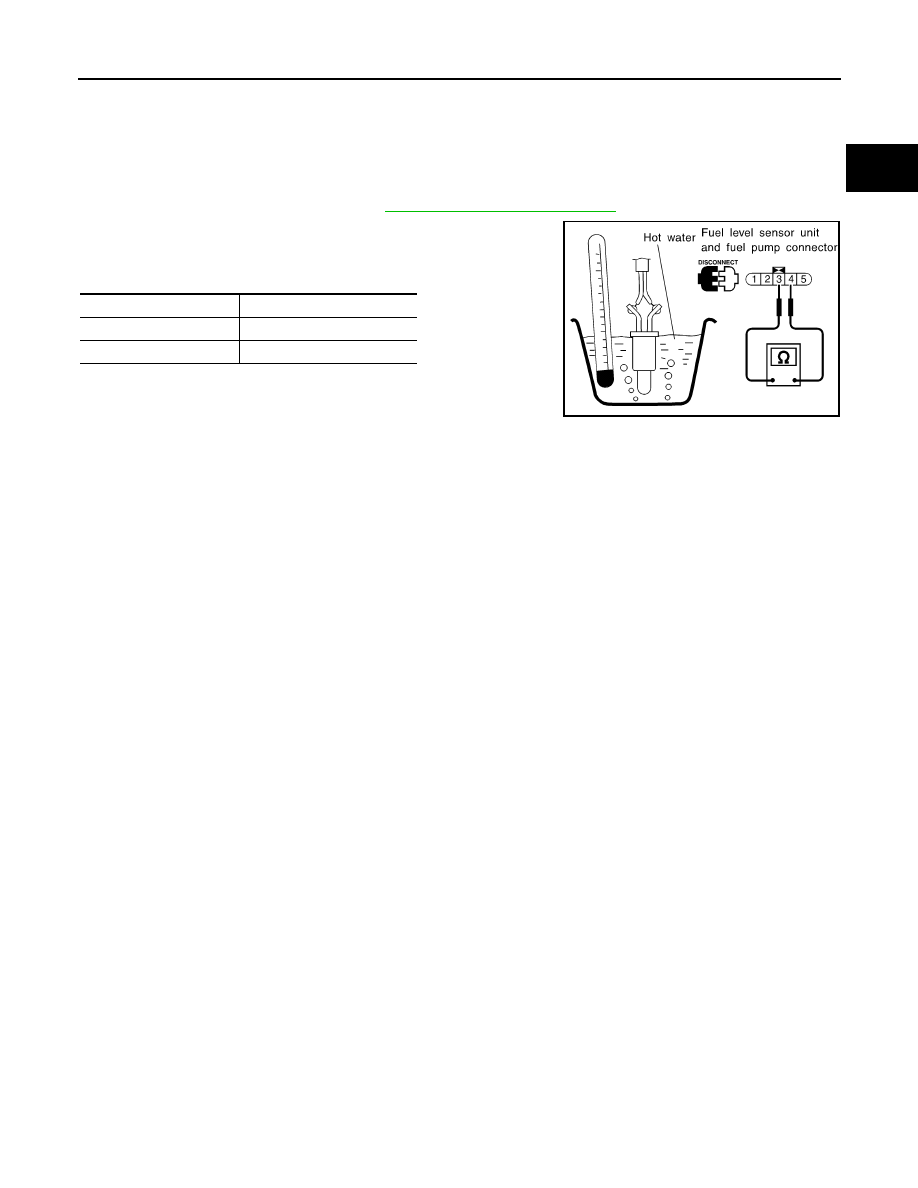

FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit. Refer to

FL-11, "Removal and Installation"

.

2. Check resistance between “fuel level sensor unit and fuel pump”

terminals 3 and 4 by heating with hot water or heat gun as

shown in the figure.

Temperature

°

C (

°

F)

Resistance k

Ω

20 (68)

2.3 - 2.7

50 (122)

0.79 - 0.90

SEF476YA

August 2012

2012 Pathfinder