Nissan Pathfinder (2011 year). Manual - part 389

CYLINDER HEAD

EM-223

< REMOVAL AND INSTALLATION >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

3. Heat the cylinder head to 110

°

to 130

°

C (230

°

to 266

°

F) by

soaking it in heated oil.

4. Cool the valve seats well with dry ice. Force fit the valve seat into the cylinder head.

WARNING:

• Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

CAUTION:

• Avoid directly touching cold valve seats.

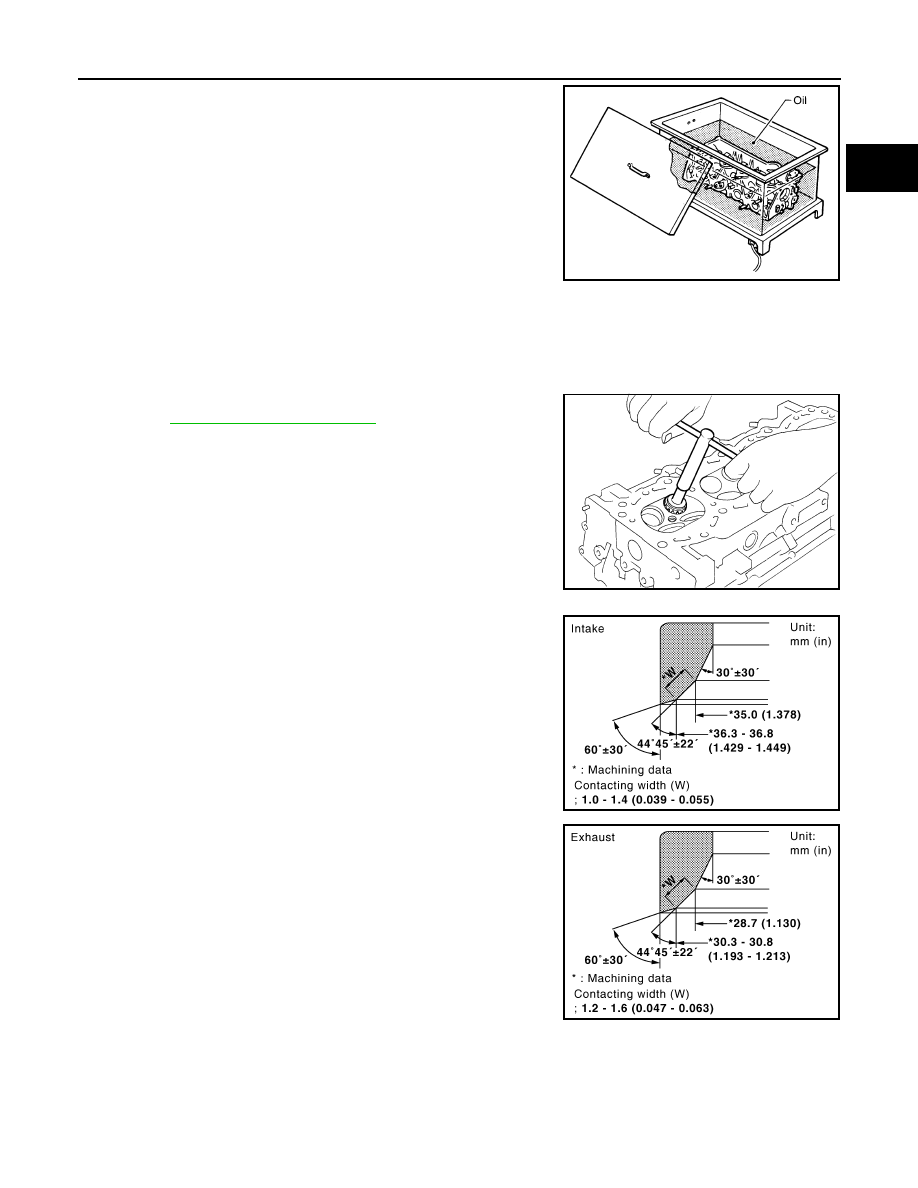

5. Finish the seat to the specified dimensions using suitable tool.

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on the cutter or cutting many different times may

result in stage valve seat.

6. Grind to obtain the dimensions indicated as shown.

• Using compound, grind to adjust valve fitting.

7. Check again for normal contact.

VALVE SPRING SQUARENESS

SEM008A

SEM934C

KBIA2531E

KBIA2544E

2011 Pathfinder