Nissan Pathfinder (2010 year). Manual - part 428

GI-30

< PRECAUTION >

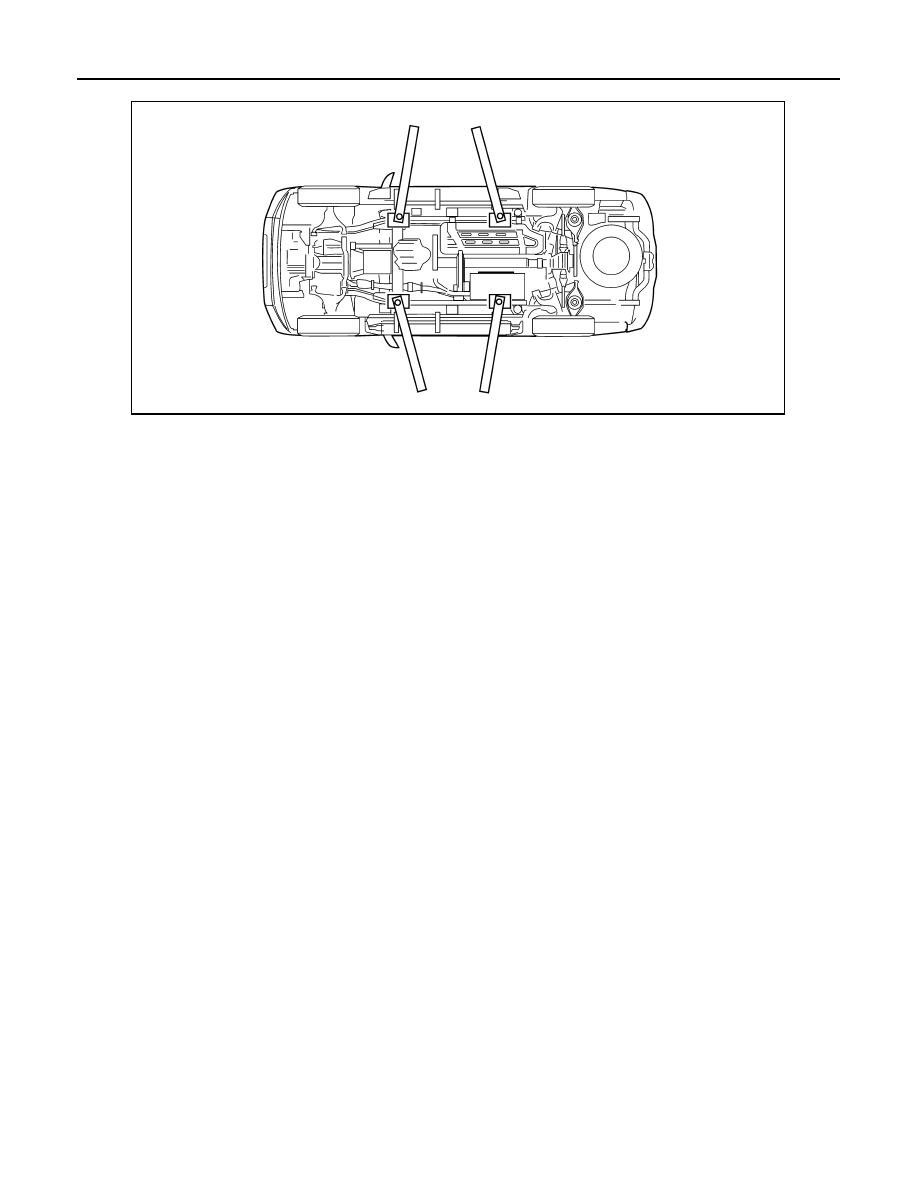

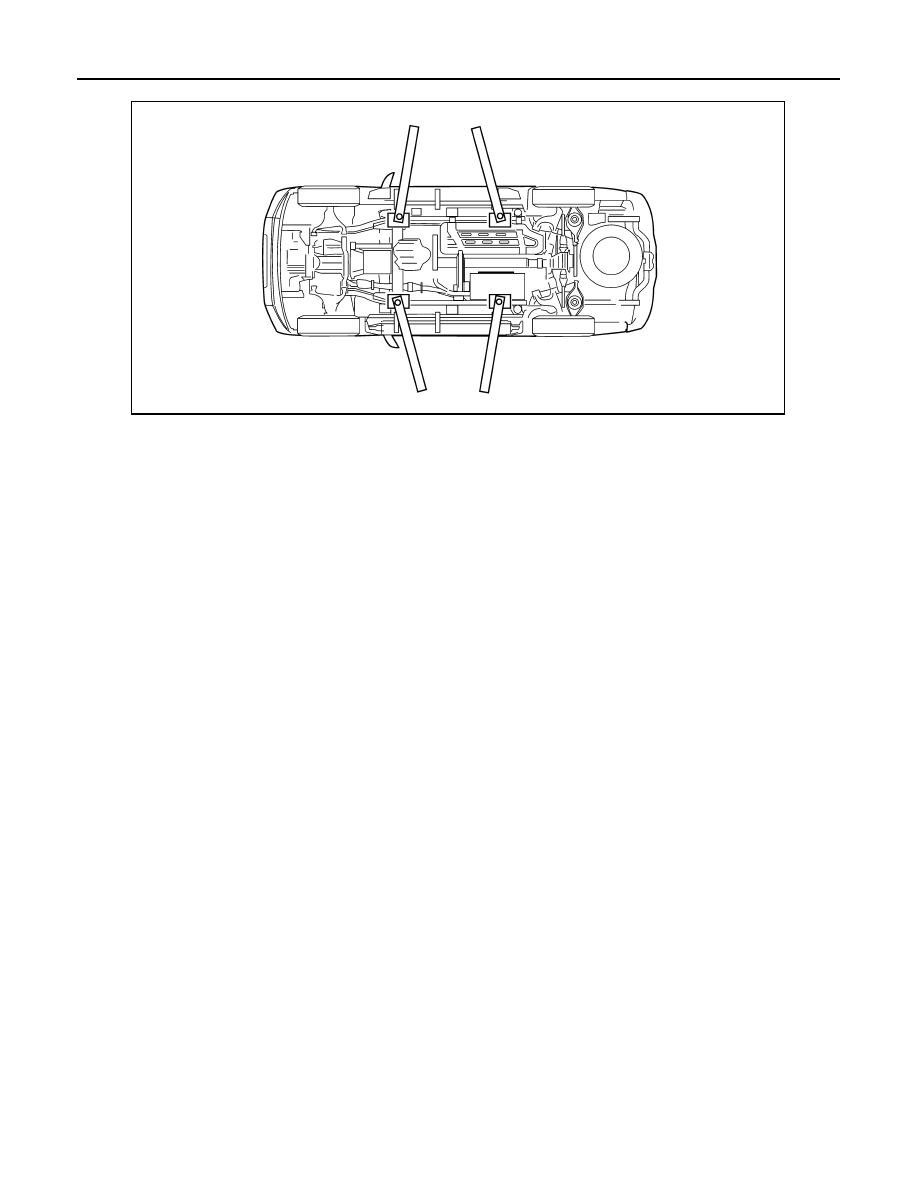

LIFTING POINT

• When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, or fuel lines.

WAIA0029E

2010 Pathfinder

|

|

|

GI-30 < PRECAUTION > LIFTING POINT • When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, or fuel lines. WAIA0029E 2010 Pathfinder |